UV Laser Marking Machine

UV Laserr Marking Machine

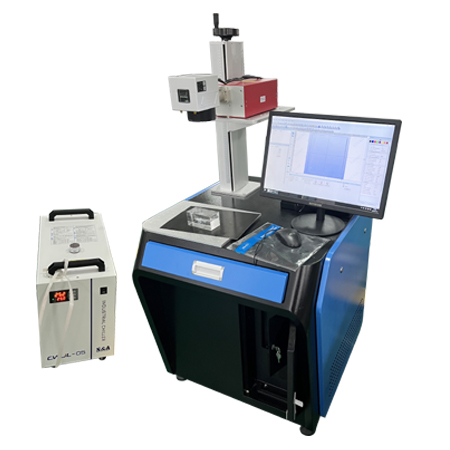

The UV Laser Marking Machine offers high-precision engraving with a 355nm wavelength, ensuring ultra-fine, clean markings on a variety of materials. It is designed for heat-sensitive surfaces, minimizing thermal damage during the marking process.

Advantages:

- Precision: High-detail engravings

- No Heat Damage: Safe for sensitive materials

- Speed: Fast marking process

- Versatility: Works on various materials

Perfect for industries needing accurate, clean engravings with minimal thermal effects.

Standard version-UV Laser Marking Machine

Standard version-Mini model

Standard version-pedestal model

UV Laser Marking Machine with Optional part

Online Flying UV laser Marking Machine

CCD Visual Position UV Laser Marking Machine

3D UV Laser Marking Machine

UV Laser Marking Machine – The Ultimate Tool for Precise, High-Quality Engraving

Are you tired of blurry, inconsistent engravings on your products? The UV Laser Marking Machine is here to change that. With its 355nm wavelength, this machine delivers ultra-fine, high-precision markings on plastics, metals, glass, and other heat-sensitive materials. Whether you’re in electronics, medical devices, jewelry, or cosmetics packaging, the UV Laser Marking Machine is the tool you need to elevate your product’s quality.

Why This Machine is a Game Changer:

- Unmatched Precision: Achieve sharp, detailed engravings that are literally a fraction of a micron. No more blurred or inconsistent marks—just pure precision.

- No Heat Damage: Unlike traditional lasers, the UV laser won’t damage or warp your delicate materials. It’s perfect for plastics and coated materials that need precision without the heat.

- Super Fast: Time is money, right? This high-speed laser machine doesn’t just deliver top-notch results; it does it quickly, so you can get more done in less time.

- Total Versatility: Whether you’re marking logos, serial numbers, or customized designs, the UV Laser Marking Machine can handle it all—on electronics, medical devices, jewelry, and much more.

Top Benefits You Can’t Ignore:

- Clean, Sharp Results: The UV Laser Marking Machine delivers precision engravings that stand out—perfect for that extra touch of professionalism.

- Eco-Friendly & Efficient: This energy-efficient machine doesn’t just save you time, it also reduces waste, making it a more sustainable choice for your business.

- Built to Last: The engravings you make with the UV laser are permanent, resistant to wear, and incredibly durable, making them perfect for high-end products that require long-lasting identification.

UV Laser Marking Machine – Specifications

| Parameter | Description |

|---|---|

| Laser Type | UV Laser (355nm) |

| Laser Power Options | 3W, 5W, 10W, 20W |

| Marking Area | 110mm x 110mm, 150mm x 150mm, 200mm x 200mm |

| Marking Speed | Up to 8000mm/s |

| Marking Depth | 0.01mm – 1mm (depending on material) |

| Beam Quality | M2 < 1.5 |

| Cooling Method | Air or Water Cooling |

| Minimum Line Width | 0.01mm |

| Repeat Accuracy | ≤ 0.002mm |

| Working Life | ≥ 100,000 hours |

| Power Supply | AC 110V/220V ±10%, 50/60Hz |

| Operating System | Windows-based Software (EZCAD, etc.) |

| Material Compatibility | Plastics, Metals, Glass, Ceramic, Coated Surfaces |

| Machine Dimensions | 800mm x 750mm x 500mm |

| Weight | 50kg – 100kg (depending on configuration) |

These UV Laser Marking Machine parameters ensure high-precision engraving and marking for a variety of applications, from electronics to jewelry. The machine’s versatility and speed make it a perfect choice for industries that demand high-quality and efficient laser marking solutions.

Ready to take your engraving game to the next level? The UV Laser Marking Machine will boost your productivity, improve your product quality, and give you that competitive edge. Don’t settle for anything less than perfection—get the precision and speed you deserve with the UV Laser Marking Machine.

UV Laser Marking Machine – The Ultimate Advantage for Your Business

Looking for a laser marking machine that delivers precision, speed, and unmatched quality? The UV Laser Marking Machine is the perfect solution, offering advantages that other laser systems just can’t match.

1. Superior Precision

The UV Laser Marking Machine delivers sub-micron precision, ensuring your engravings are crisp, clean, and incredibly detailed. Whether you’re marking logos, serial numbers, or intricate designs, you’ll get perfect results every time. With the ability to etch the most fine details, this machine is ideal for high-end products where precision is paramount.

2. No Heat Damage

One of the biggest problems with traditional laser systems is the heat distortion they cause on sensitive materials. Not with the UV Laser Marking Machine! This machine operates with minimal heat, making it perfect for delicate surfaces like plastics, thin metals, and coated materials. You can get high-quality engravings without worrying about damage or warping.

3. Faster Production, More Efficiency

In today’s fast-paced market, speed is key. The UV Laser Marking Machine doesn’t just mark quickly; it does so without sacrificing quality. With its high-speed capabilities, you’ll be able to mark more products in less time, maximizing your productivity and improving your bottom line.

4. Eco-Friendly and Cost-Effective

The UV Laser technology is energy-efficient and eco-friendly, producing minimal waste while maximizing output. You’ll save on operational costs and contribute to a more sustainable future—all without compromising performance. It’s a win-win.

5. Long-Term Durability

When you invest in a UV Laser Marking Machine, you’re getting a tool built to last. Designed for low-maintenance and high-reliability, this machine will keep delivering top-quality results for years. Its durable construction means fewer repairs and interruptions, saving you time and money in the long run.

6. Versatile Applications

From electronics to medical devices, jewelry, and cosmetics, the UV Laser Marking Machine can handle a variety of materials and industries. Whether you need to mark serial numbers, barcodes, or logos, this machine adapts to your needs, giving you ultimate flexibility.

Why Choose the UV Laser Marking Machine?

- Precision that delivers flawless engravings

- Minimal heat to protect your delicate materials

- High-speed operation to increase productivity

- Eco-friendly and cost-efficient

- Built to last, with low maintenance

The UV Laser Marking Machine is the perfect tool for businesses that demand accuracy, speed, and versatility. Stop settling for less and start delivering top-tier engravings with every product. Your customers will notice the difference—and so will your bottom line.

UV Laser Marking Machine Applications: Unleashing Precision on Glass, Plastic, and PCBs

If you’re looking for top-tier precision and unmatched quality for delicate materials, the UV Laser Marking Machine is your go-to solution. With its ultra-short wavelength (355nm), this machine offers flawless and non-contact marking, ensuring high-quality results without damaging your products. Let’s dive into the key applications where the UV Laser truly shines:

1. Glass Marking: Clean, Sharp, and Lasting Engravings

When it comes to glass marking, whether you’re working on luxury items, bottles, or fine glassware, the UV Laser Marking Machine delivers sharp, high-contrast engravings that won’t cause any cracks or heat distortion. Whether it’s for branding, logos, or QR codes, the UV laser ensures your designs are precise and permanent.

2. Plastic Marking: Crisp, Clear Details Without Heat Damage

For industries using plastics like consumer electronics, automotive parts, and medical devices, UV laser technology stands out. Unlike traditional lasers, UV lasers mark plastics without causing melting, warping, or color fading. Whether you’re working with ABS, PVC, or PC, you can get clean, long-lasting marks that remain sharp over time.

3. PCB Marking: Ultra-Precise, Clean, and Reliable

When it comes to marking printed circuit boards (PCBs), UV lasers are unbeatable. The high precision and minimal heat generation mean you can mark serial numbers, barcodes, and logos on PCBs without worrying about damaging sensitive components. UV lasers create highly legible and permanent markings that maintain the integrity of your electronics.

4. Cosmetics & Packaging: Fine, Non-Damaging Marks

For cosmetic packaging and small glass or plastic containers, UV lasers provide the perfect solution for intricate designs and branding. With no heat distortion and non-contact marking, you get detailed and clean engravings that elevate the product’s appeal without damaging the material.

Why Choose UV Laser Marking?

The UV Laser Marking Machine is the ultimate tool for industries demanding precision, non-damaging marks, and long-lasting engravings on materials like glass, plastic, and PCBs. If you’re in the electronics, cosmetics, or jewelry industries, the UV laser is your best choice for high-quality, clear, and permanent marks.

With the ability to work on delicate surfaces while maintaining exceptional accuracy, the UV laser will help your business produce premium-quality products that stand out in the market.

UV Laser Marking Machine vs Fiber Laser Marking Machine vs CO2 Laser Marking Machine: What’s the Difference?

If you’re looking to mark, engrave, or cut with precision and clarity, choosing the right laser marking machine is crucial. But with so many options out there, it can get confusing. Let’s break down the key differences between the UV Laser, Fiber Laser, and CO2 Laser machines to help you make the smartest choice for your business.

1. Precision and Detail: Who Wins?

UV Laser Marking Machine: Hands down, the UV Laser wins when it comes to fine, detailed work. If you need to mark small parts, intricate logos, or serial numbers with sub-micron precision, the UV laser is your best option. It’s a game-changer for high-precision engraving on plastics, glass, and coated metals. No other laser comes close to achieving the level of detail you’ll get with this machine.

Fiber Laser Marking Machine: Great for metals, especially for engraving on stainless steel, aluminum, and other industrial metals. However, it lacks the subtlety of the UV Laser, especially for marking delicate plastics or doing fine engravings on small, detailed designs.

CO2 Laser Marking Machine: While excellent for marking non-metals like wood, plastics, and leather, the CO2 Laser doesn’t quite stack up when it comes to precision on metal or delicate details. It’s good for larger areas but struggles with fine engravings.

2. Heat Generation: Which One Keeps It Cool?

UV Laser Marking Machine: The UV Laser uses a cooler process—it operates with minimal heat, which means it won’t damage heat-sensitive materials. You get fine markings without worrying about warping or melting delicate materials. This makes it ideal for marking plastics, coated surfaces, and thin metals.

Fiber Laser Marking Machine: The Fiber Laser generates more heat, which can be problematic for plastics or thin metals. If you’re not careful, this can lead to distortion or damage to your workpiece.

CO2 Laser Marking Machine: Similar to the Fiber Laser, the CO2 Laser generates more heat. It can be problematic when working with plastic materials and may cause burn marks or surface damage on thin or delicate items.

3. Material Versatility: Which One Handles More?

UV Laser Marking Machine: The UV Laser is incredibly versatile. It marks a wide variety of materials, including plastics, glass, metals, ceramics, and even coated surfaces. It’s perfect for industries like electronics, medical devices, jewelry, and cosmetics, where you need flexibility to work with different materials without compromising quality.

Fiber Laser Marking Machine: Fiber lasers are ideal for marking metals, including stainless steel, aluminum, and brass. However, they struggle with materials like plastics and glass—you’re pretty much limited to metals.

CO2 Laser Marking Machine: The CO2 Laser is great for non-metals like wood, plastics, and leather. But it can’t touch metal marking or coated surfaces, which makes it less versatile than both the UV Laser and Fiber Laser when it comes to material variety.

4. Speed: Which One is Faster for Your Jobs?

UV Laser Marking Machine: Fast and efficient when it comes to high-precision, detailed marking. It can keep up with both speed and quality, especially for small or delicate parts. So, if you’re marking a lot of small items, the UV laser can save you time while still delivering perfect quality.

Fiber Laser Marking Machine: Very fast for metal marking. If you’re working with metals and need to mark large quantities, the Fiber Laser will get the job done quickly.

CO2 Laser Marking Machine: Speed can vary depending on the material, but the CO2 Laser is generally slower compared to the other two, especially when working with fine details. It’s best for larger-area markings on non-metals.

5. Cost: Which One Gives You More Value?

UV Laser Marking Machine: While UV Lasers tend to have a higher initial price, their precision, versatility, and minimal heat generation mean you’ll get long-term value from this machine. If your business requires high-quality, fine-detail engraving on a variety of materials, the UV Laser will pay for itself.

Fiber Laser Marking Machine: Lower upfront cost compared to the UV Laser, but you’ll miss out on working with non-metal materials and delicate designs. Good value for metal marking, but limited versatility.

CO2 Laser Marking Machine: Affordable, but it’s only a good choice if you’re working with non-metals. If you need to mark metals or fine details, it may not be the best investment in the long run.

Which Laser is Right for You?

- If you need ultra-precise, detailed engravings on multiple materials like plastics, glass, and metal, go with the UV Laser Marking Machine.

- If you’re focused on high-speed metal marking for industrial applications, then the Fiber Laser is your best option.

- If you’re working primarily with non-metals like wood, plastics, and leather, the CO2 Laser might still work for your needs, but it lacks the versatility of the other two.

Now you’ve got a clearer picture of what each laser marking machine brings to the table—making it easier for you to choose the one that best fits your needs!

Frequently Asked Questions (FAQ) – UV Laser Marking Machine

1️⃣ What is a UV Laser Marking Machine?

A UV Laser Marking Machine uses a ultraviolet laser with a short wavelength (355nm) to create precise and high-contrast markings on a wide range of materials. This technology is perfect for marking delicate, high-precision, or heat-sensitive materials that cannot withstand traditional laser types like CO2 or fiber lasers. It’s ideal for fine engraving, text, logos, and barcode marking.

2️⃣ What materials can be marked with a UV Laser Marking Machine?

A UV Laser Marking Machine is highly versatile and can mark a variety of materials, including:

- Plastics: ABS, PC, PVC, nylon, and more.

- Glass: Including glass bottles, windows, and mirrors.

- Ceramics: Porcelain, tiles, etc.

- Coated metals: Such as anodized aluminum, coated stainless steel, and more.

- Silicone: Used in medical devices and electronic applications.

- Painted or coated surfaces: Leaves a clean and sharp mark without damaging the base material.

It’s perfect for delicate materials or items requiring high-detail marking, like electronics, medical devices, luxury goods, and more.

3️⃣ How does a UV Laser Marking Machine work?

The UV laser generates short-wavelength light that is absorbed by the material. This causes minimal heat accumulation and results in precise, clean marks. The short wavelength ensures high resolution and enables the machine to engrave or mark fine details with accuracy down to microns. The UV laser is especially suitable for applications where traditional lasers would cause heat distortion or material degradation.

4️⃣ What is the marking speed of the UV Laser Marking Machine?

The marking speed of a UV Laser Marking Machine can vary based on the specific model and the complexity of the marking design. Typically, speeds range from 1000mm/s to 8000mm/s depending on the application. However, due to the precision required for UV laser marking, the speed is often balanced with accuracy.

5️⃣ What is the laser power of the UV Laser Marking Machine?

The UV Laser Marking Machine typically comes with a laser power range of 3W to 15W. Lower power options (around 3W-5W) are suitable for fine, detailed work, while higher power options (around 8W-15W) can be used for deeper engraving or cutting on thicker or harder materials.

6️⃣ Is the UV Laser Marking Machine easy to operate?

Yes! The UV Laser Marking Machine is designed to be user-friendly, with intuitive software that allows you to easily upload designs, set parameters, and start the marking process. It typically has a touchscreen interface and automatic calibration to ensure accuracy. Whether you’re a beginner or an experienced user, the machine offers easy setup and operation.

7️⃣ What industries benefit from the UV Laser Marking Machine?

The UV Laser Marking Machine is widely used in industries that require high-precision and clean marking on sensitive materials, such as:

- Electronics: Marking parts like PCBs, mobile phones, and circuit boards.

- Medical Devices: Engraving serial numbers, logos, and barcodes on surgical instruments, implants, and medical packaging.

- Cosmetics: Engraving logos or text on cosmetic packaging or luxury items.

- Jewelry: Marking logos, serial numbers, and personalized designs on delicate jewelry pieces.

- Packaging: Creating clear, high-quality markings on packaging materials, such as bottles and containers.

- Luxury Goods: Engraving serial numbers or authenticity marks on high-end goods.

8️⃣ What is the precision of the UV Laser Marking Machine?

The UV laser provides extremely high precision with an engraving accuracy of up to 0.001mm. This makes it perfect for applications that require fine details such as small text, logos, and high-contrast designs.

9️⃣ What are the advantages of using a UV Laser Marking Machine?

- High Precision: Achieve sharp, detailed markings with minimal distortion.

- No Heat Damage: The UV laser minimizes heat-affected zones, ensuring that delicate materials remain intact.

- Versatile Applications: Can be used on a wide range of materials, including plastics, glass, and coated metals.

- Non-contact Process: The UV laser doesn’t physically touch the material, which helps to preserve the integrity of the surface.

- Environmentally Friendly: UV lasers don’t require consumables, such as ink or chemicals, making them a cleaner solution.

- Long Service Life: The UV laser has a long lifespan and requires very little maintenance.

🔟 Can the UV Laser Marking Machine be used for both engraving and cutting?

Yes, the UV Laser Marking Machine can perform both engraving and cutting, depending on the material and the power setting. While it is more commonly used for engraving due to its high precision and minimal heat output, it can also cut through thin materials like plastic and coated metals with the right settings.

1️⃣1️⃣ What is the maintenance required for the UV Laser Marking Machine?

The maintenance requirements are relatively low for the UV Laser Marking Machine. Key maintenance tasks include:

- Regular cleaning of the lens and mirrors to ensure optimal performance.

- Check and replace the air filter regularly to keep the system cool.

- Inspect the laser source for signs of wear or damage.

- Software updates to ensure the latest features and improvements.

1️⃣2️⃣ What is the price range of the UV Laser Marking Machine?

The price of the UV Laser Marking Machine typically ranges from $10,000 to $40,000, depending on the model and configuration. Factors such as the power, marking area, and additional features like the cooling system can affect the final price.

1️⃣3️⃣ Is the UV Laser Marking Machine suitable for high-volume production?

Yes, the UV Laser Marking Machine is designed to handle high-volume production runs, offering fast marking speeds and long-lasting performance. Its durable design and low maintenance requirements make it a reliable choice for industries that need to process large quantities of parts consistently.

UV Laser Marking Video

Laser Marking Plastic

Laser Marking Gem stone

Laser Marking Plastic seals

Online Flying Laser Marking

CCD Visual Position Laser Marking

3D Laser Marking

Request a Quote for UV Laser Marking Machine

SISMAR LASER has UV laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your UV laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how UV laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Create Flawless Jewelry & Crafts with UV Laser Seashell CuttingFebruary 10, 2026 - 4:14 am

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am