High-Precision Vision Laser Marking Machine for Charging Plugs & Chargers

CCD Vision Laser Marking Machine

High-Precision Vision Laser Marking Machine

Take your mobile accessory production to the next level. Our vision laser marking machine delivers fast, accurate, and permanent markings for charging plugs, earphone covers, power banks, phone cases, and more.

With a high-resolution CCD camera and smart vision software, it automatically detects and positions each product, eliminating errors and waste. The non-contact process keeps surfaces flawless while marking logos, serial numbers, QR codes, and custom designs that last.

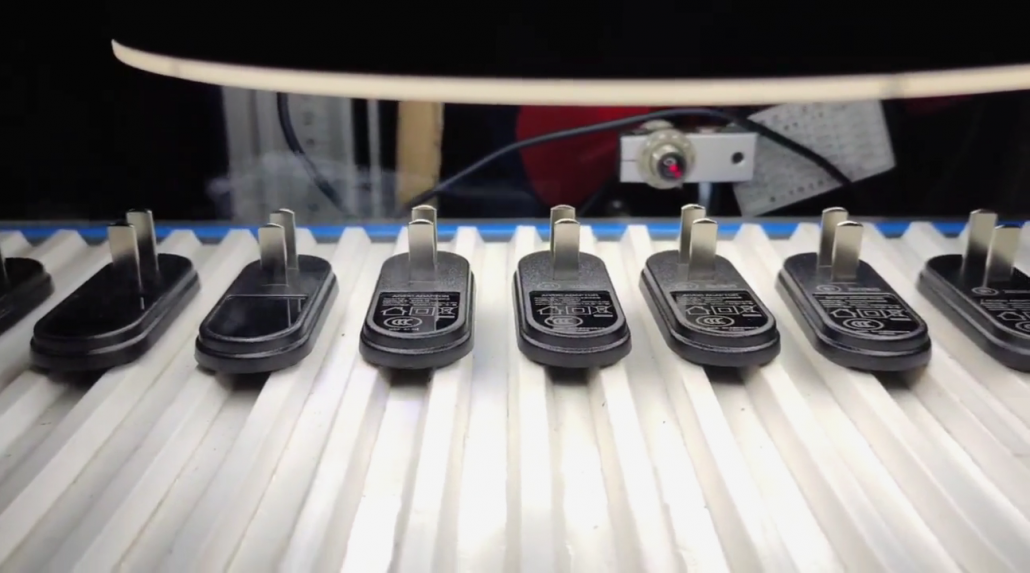

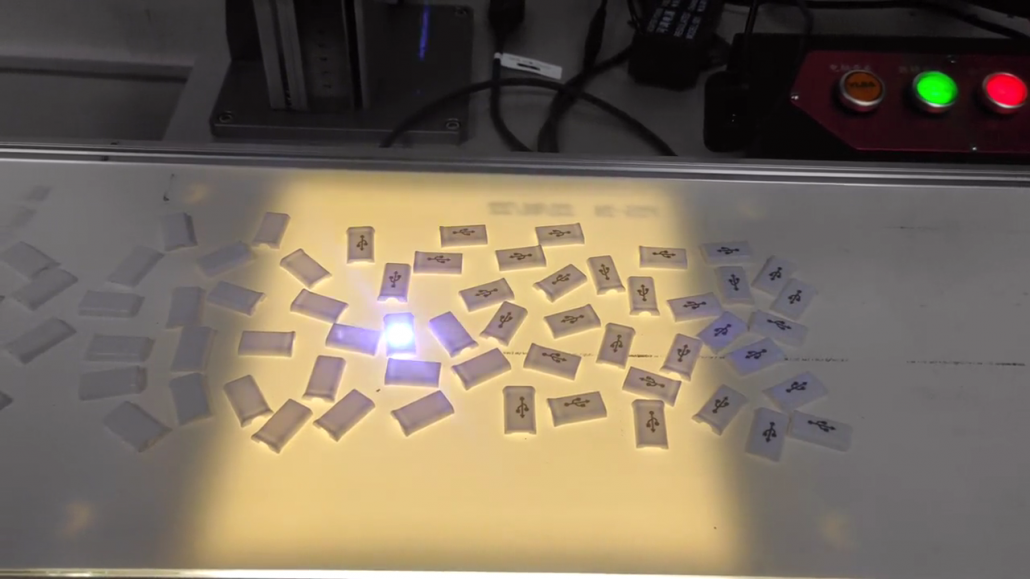

CCD visual Position Laser Marking Machine Photo

High-Precision Vision Laser Marking Machine: Make Your Mobile Accessories Stand Out

If you’re a mobile accessories manufacturer, you already know this: the quality and look of your products can make or break a sale. Traditional marking methods are slow, inaccurate, and prone to mistakes. That’s where our high-precision vision laser marking machine comes in.

It’s built for charging plugs, earphone covers, power banks, phone cases, and more—delivering crisp, permanent markings every single time. Logos, serial numbers, QR codes, or custom designs—you name it, it handles it.

Why You’ll Love This Machine

1. Pinpoint Accuracy Every Time

High-resolution CCD camera + smart vision software

Automatically detects and positions your products—no manual alignment needed

Result? Zero mistakes, zero waste

2. Lightning-Fast Marking

High-speed galvanometer system + optimized algorithms

Cuts marking time down to milliseconds

Produces more parts per hour, boosting your production efficiency

3. Non-Contact, No Damage

Laser marking is non-contact

Keeps high-end surfaces like power banks and earphones pristine

Perfect for products where looks matter

4. Long-Lasting Marks with Anti-Counterfeit Benefits

Wear-resistant and environment-proof

Helps with product traceability and anti-counterfeiting

Keeps your brand professional and trustworthy

Perfect For These Applications

Charging Plugs & Chargers: Logos, model numbers, CE/FCC marks

Bluetooth & TWS Earphones: Brand name, left/right labels, anti-counterfeit codes

Power Banks & Mobile Chargers: Capacity, production date, safety warnings

Phone Cases & Covers: Custom patterns, text, textures—boosts product value

No matter the batch size, from small runs to mass production, this machine handles it all.

Quick Specs

| Parameter | Specification |

|---|---|

| Laser Type | Pulsed Fiber Laser / UV Laser (optional) |

| Laser Power | 20W / 30W / 50W (Fiber Laser); 3W / 5W (UV Laser) |

| Marking Area | 110×110mm (standard); optional 175×175mm, 200×200mm |

| Marking Speed | ≤7000mm/s |

| Minimum Line Width | 0.01mm |

| Minimum Character | 0.1mm |

| Positioning Accuracy | ±0.01mm |

| Vision System | High-res CCD + smart vision software |

| Supported Files | PLT, DXF, AI, BMP, JPG, PNG… |

| Cooling | Air-cooled |

| Power | AC 220V, ≤1000W |

| Machine Size | Approx. 700×600×1350mm |

| Software | Proprietary control software, multi-OS |

Customizable options available—adjust laser power, marking area, and software features to fit your production needs.

What This Machine Does For You

Boost Product Quality & Brand Image

Sharp, permanent markings make your products look premium

Instantly increases brand credibility

Reduce Costs & Labor Dependence

Automated vision system reduces need for skilled operators

Lowers labor costs and human error

Expand Product Lines & Business Opportunities

Flexible marking handles custom orders quickly

Opens new revenue streams with personalized products

Why Choose Laser Marking Over Traditional Marking for Mobile Accessories?

If you’re in the mobile accessories business—chargers, earphones, power banks—you already know: details matter. The logo has to be sharp, the serial number must be readable, and the surface can’t get damaged. Here’s where laser marking simply outperforms old-school methods like ink printing or mechanical engraving:

Pinpoint Precision – Laser hits accuracy within ±0.01mm, perfect for tiny, curved, or irregular parts. Traditional methods? They struggle to stay consistent.

Permanent & Clean – No fading, no smudging, no scratching. Your branding stays sharp for the lifetime of the product.

Faster Production – High-speed lasers mark products in milliseconds. Traditional printing or engraving slows you down with manual setups and extra steps.

Non-Contact = No Damage – The laser never physically touches your product, so even glossy power banks or delicate earbud cases stay flawless.

Flexible & Customizable – Logos, QR codes, barcodes, anti-counterfeit marks… you name it, the laser does it—without swapping tools or consumables.

Cost-Effective – Forget ink refills or worn engraving bits. Lasers require minimal maintenance and cut long-term production costs.

Laser Marking vs. Traditional Marking for Mobile Accessories

| Traditional Marking | Laser Marking |

|---|---|

| Low precision – Printing or engraving struggles on tiny or irregular parts | High precision – ±0.01mm accuracy, perfect for chargers, earbud cases, power banks |

| Fades or blurs – Ink wears off, engraving loses clarity over time | Permanent clarity – Marks stay sharp, wear-resistant, and fade-proof |

| Slow & labor-intensive – Manual alignment and multiple steps required | High speed – Up to 7000mm/s marking speed boosts productivity |

| Contact process – Risk of scratches or surface damage | Non-contact – Laser leaves surfaces flawless |

| High consumable costs – Ink, molds, or engraving bits need replacement | Low maintenance – No consumables, lower long-term cost |

| Limited applications – Simple text or basic graphics only | Versatile – Logos, QR codes, barcodes, serial numbers, anti-counterfeit marks |

👉 Summary:

For mobile accessories like chargers, earphones, power banks, and cases, laser marking delivers precision, durability, and efficiency that traditional methods can’t match—helping your brand stand out while cutting production costs.

👉 Bottom line: Laser marking isn’t just “another option.” It’s the smarter, faster, and more professional way to brand mobile accessories—helping you stand out in a competitive market.

FAQ – High-Precision Vision Laser Marking Machine

Q1: What types of products can this machine mark?

A: Almost anything in mobile accessories—charging plugs, earphone covers, TWS earphones, power banks, phone cases, and more. It works on plastics, metals, and composite materials.

Q2: How precise is it?

A: Very precise. The built-in high-res CCD camera + vision software ensures markings are accurate to ±0.01mm, even on small or oddly-shaped products.

Q3: Is it easy to operate?

A: Absolutely. The software is intuitive and supports common file formats (PLT, DXF, AI, BMP, JPG, PNG, etc.). With minimal training, your team can start marking in no time.

Q4: Will it damage my products?

A: No. The laser is non-contact, so surfaces stay flawless. Perfect for high-end accessories where appearance matters.

Q5: Can it handle high-volume production?

A: Yes. High-speed galvanometer technology allows fast, stable marking for both small batches and mass production.

Q6: What types of marks can it make?

A: Logos, serial numbers, QR codes, barcodes, custom text, patterns, and anti-counterfeit codes. The marks are permanent, wear-resistant, and environment-proof.

Q7: Can the machine be customized?

A: Yes. We can adjust laser power, marking area, and software features to match your production needs.

Q8: What support do you provide?

A: We offer one-year warranty for the machine, extended warranty for the laser, 24/7 technical support, remote assistance, and training to get your team up and running quickly.

CCD Visual Position Laser Marking Video

Request a Quote for a CCD Visual Position Laser Marking Machine

SISMAR LASER has CCD visual Position laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality green laser marking machine that exceeds your expectations. You can also schedule a demo to see how green laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am

- EZCAD common errorMarch 18, 2025 - 2:09 am