Descripción

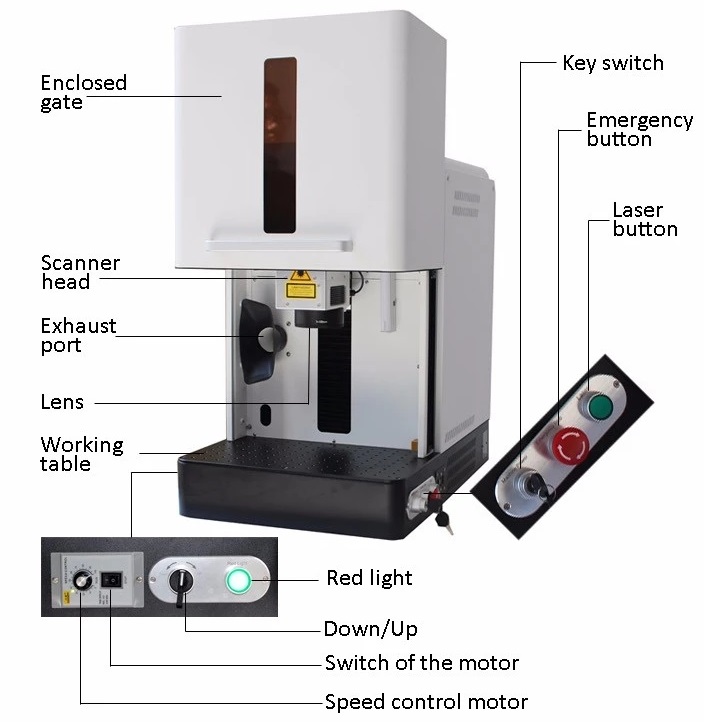

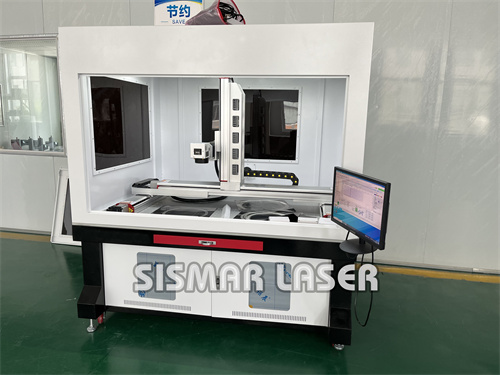

Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora: Precisión, Seguridad y Versatilidad para Cada Necesidad

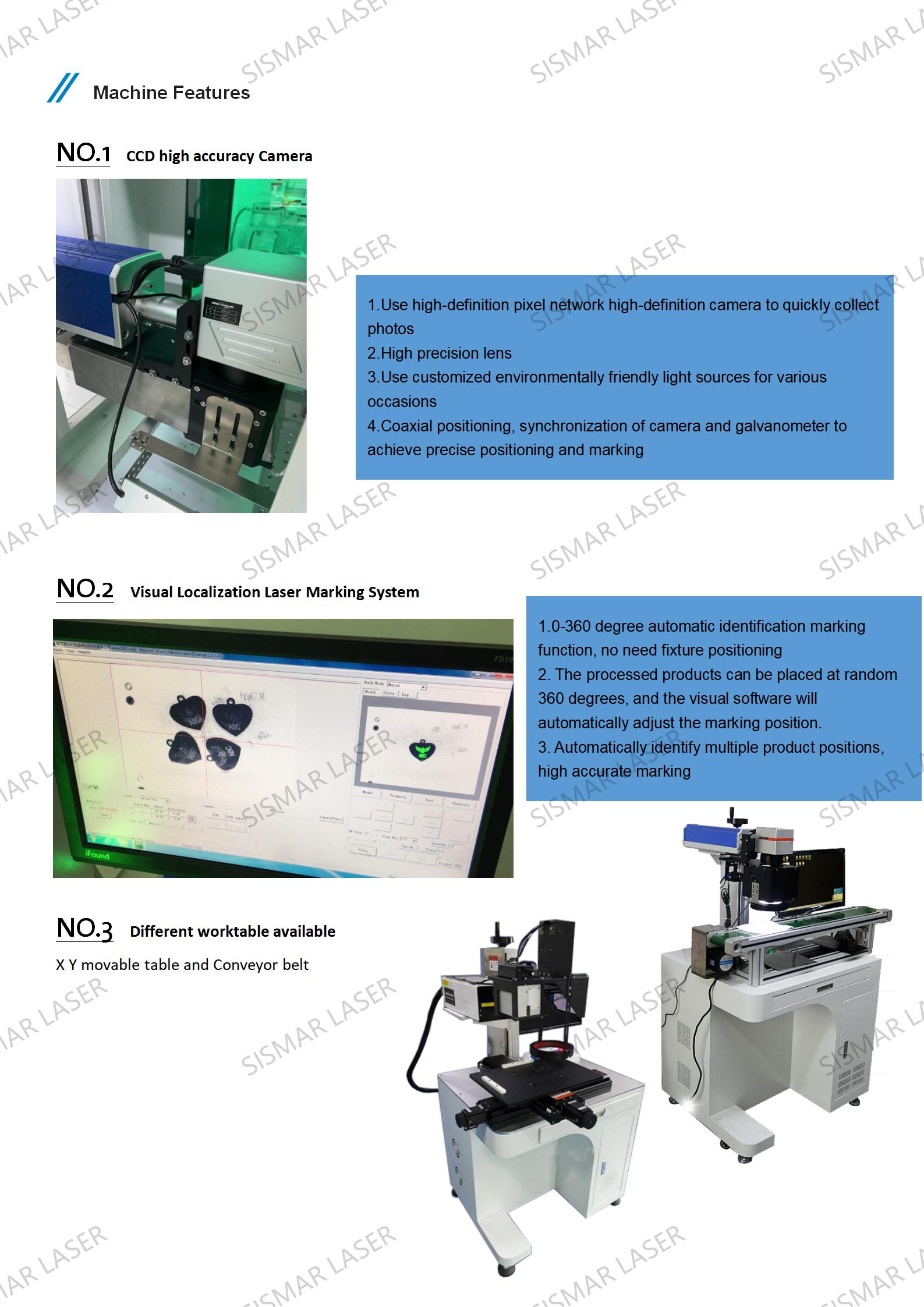

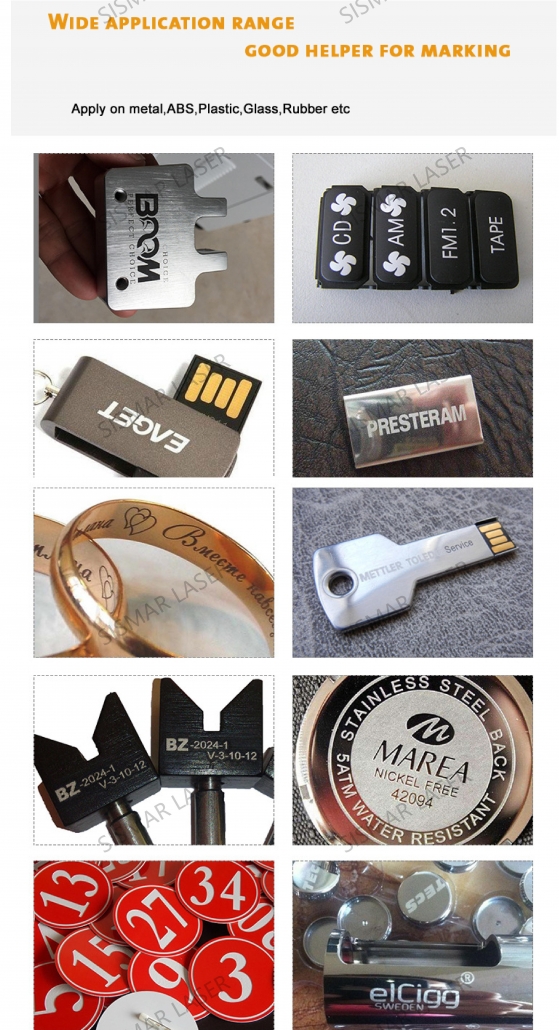

¿Buscas mejorar tu capacidad de marcado láser? La Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora es la solución ideal. Ya sea que necesites marcar joyería delicada, cortar componentes industriales o grabar electrónicos, esta máquina compacta, segura y de alto rendimiento es la opción perfecta. Con opciones de potencia que van de 20W a 200W, está diseñada para satisfacer las demandas de cada proyecto.

Por qué necesitas la Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora:

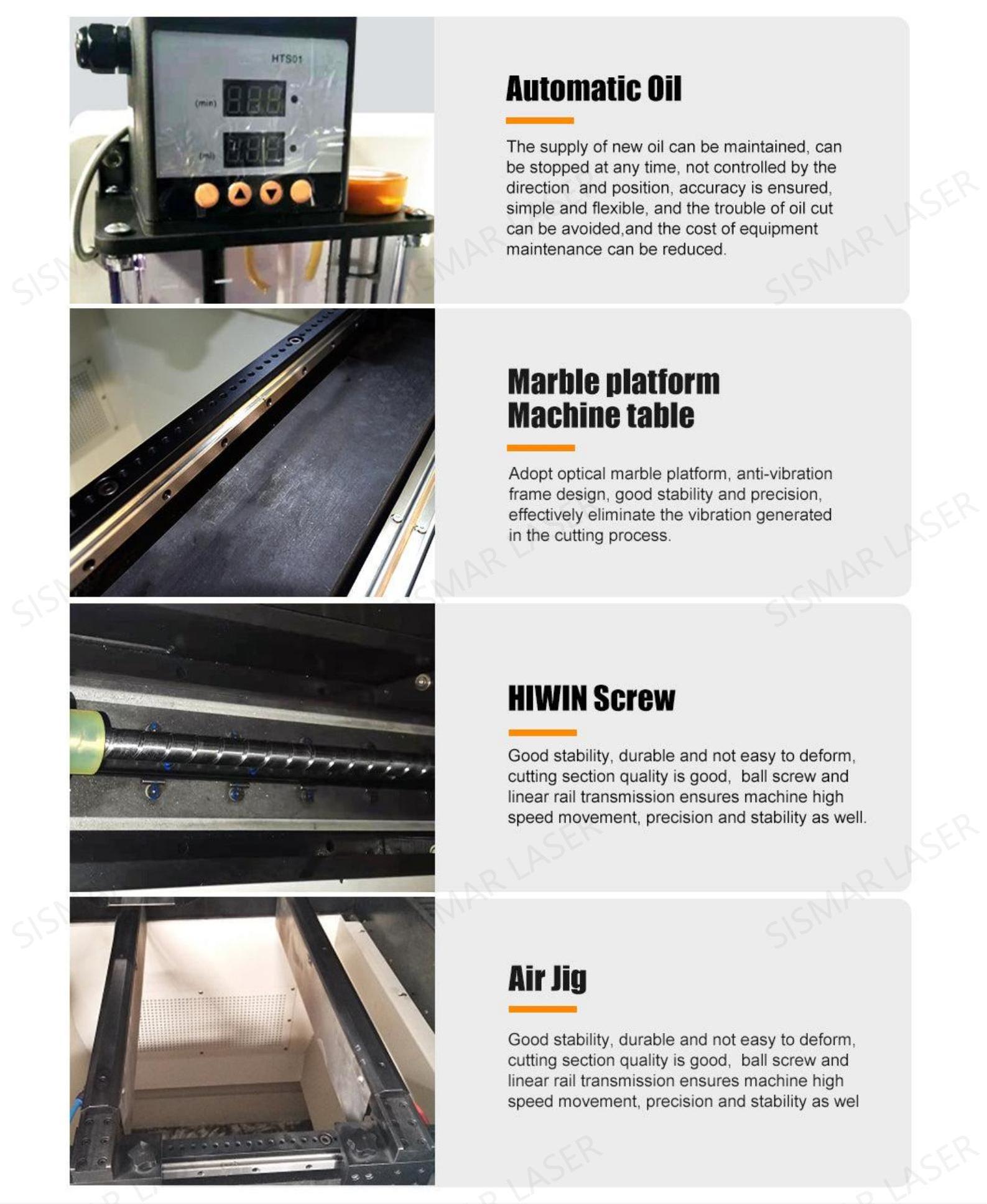

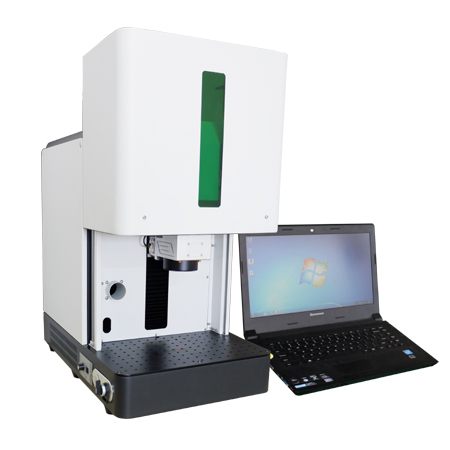

🔹 Seguridad ante todo: Con una cubierta protectora incorporada, la Mini Fiber Laser garantiza la seguridad de los operadores en todo momento. También cuenta con un pilar elevador eléctrico para ajustes fáciles de altura, lo que la hace perfecta para materiales y piezas de trabajo de diferentes tamaños.

🔹 Trabajo más limpio y eficiente: El área de trabajo sellada, combinada con un avanzado sistema de recuperación de polvo, asegura que materiales como oro, plata y otros materiales finos sean manejados con la máxima eficiencia. Perfecta para grabado y corte de joyería, el sistema asegura un espacio de trabajo más limpio y una extracción más eficaz.

🔹 Potencia para cada necesidad: Elige entre opciones de 20W, 30W, 50W, 60W, 100W o 200W, dependiendo de tu proyecto. Desde grabados finos hasta cortes pesados, tenemos la solución ideal para ti.

🔹 Versatilidad en diversas industrias: Perfecta para joyería, electrónica, automotriz e industria, esta máquina láser es ideal para marcar, grabar y cortar una amplia gama de materiales.

🔹 Precisión: Espera marcas nítidas, limpias y duraderas en cada uso, ya sea trabajando con metales lisos, plásticos o superficies irregulares.

Opciones de Potencia y sus Aplicaciones:

🔹 20W: Perfecta para grabado de detalles finos en joyería y pequeños electrónicos. Ideal para marcar metales, plásticos y acrílicos con alta precisión.

🔹 30W: Una excelente opción para grabado más detallado en joyería y corte ligero de plásticos y metales finos. Ideal para proyectos pequeños a medianos.

🔹 50W: Para quienes necesitan más potencia, el 50W es ideal para cortar oro, plata y platino en aplicaciones de joyería, así como para grabar componentes electrónicos más grandes y placas de circuito.

🔹 60W & 100W: Estas opciones están diseñadas para grabado más profundo, corte de metales y marcado de componentes industriales más grandes. Perfecta para cortar joyería, electrónicos y piezas automotrices.

🔹 200W: El modelo más potente para corte a alta velocidad y grabado profundo en metales gruesos y materiales industriales. Ideal para producción a gran escala y aplicaciones de marcado o grabado pesado.

Aplicaciones en Diversas Industrias:

🔹 Grabado y Corte de Joyería Láser: Ya sea grabando diseños detallados en oro, plata y platino, o cortando piezas intrincadas de joyería, la Mini Fiber Laser ofrece precisión excepcional.

🔹 Marcado de Electrónica y PCB: Perfecta para marcar placas de circuito y componentes electrónicos con números de serie, logotipos y marcas comerciales, asegurando trazabilidad y protección de marca.

🔹 Piezas Industriales y Automotrices: Ya sea cortando metales o grabando piezas, la Mini Fiber Laser garantiza marcas de alta calidad y duraderas para herramientas, componentes automotrices y maquinaria industrial.

La Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora ofrece una combinación inigualable de seguridad, precisión y versatilidad. Elige la potencia perfecta para tus necesidades—ya sea en joyería, electrónica, automotriz o aplicaciones industriales, esta máquina garantiza resultados limpios, precisos y eficientes en todo momento.

🌟 ¡No esperes más! Desbloquea el potencial de tu negocio con la Mini Fiber Laser hoy mismo.

Parámetro

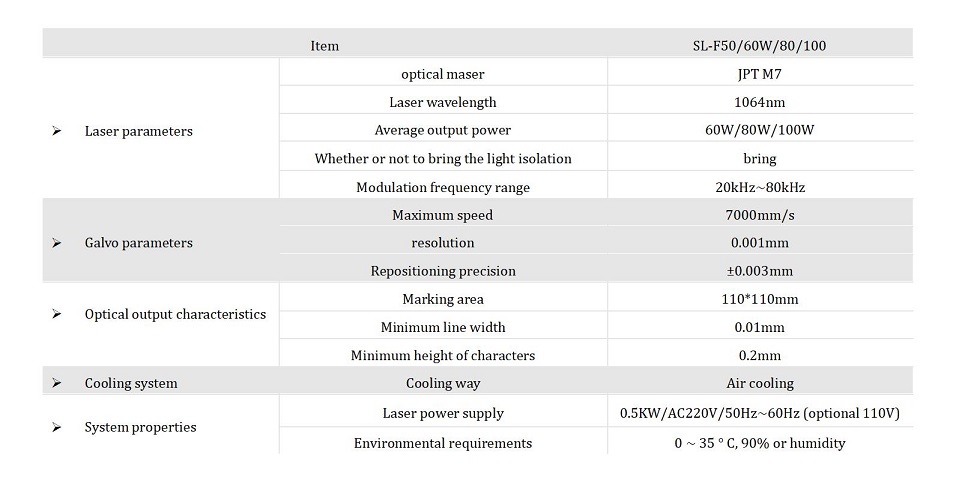

Especificaciones Técnicas de la Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora

| Parámetro |

Especificación |

| Potencia del Láser |

20W, 30W, 50W (opcional) |

| Longitud de Onda del Láser |

1064 nm |

| Tipo de Láser |

Raycus, IPG, MAX, CAS (opcional) |

| Área de Marcado |

100×100 mm a 300×300 mm (opcional) |

| Velocidad de Marcado |

≤7000 mm/s |

| Ancho Mínimo de Línea |

0.01 mm |

| Tamaño Mínimo de Caracteres |

0.2 mm |

| Frecuencia de Pulso |

20 kHz a 80 kHz |

| Sistema de Enfriamiento |

Enfriamiento por aire |

| Fuente de Alimentación |

AC 220V/50Hz o AC 110V/60Hz |

| Precisión de Repetición |

±0.15 mm |

| Profundidad de Marcado |

0.01 mm a 5 mm (opcional) |

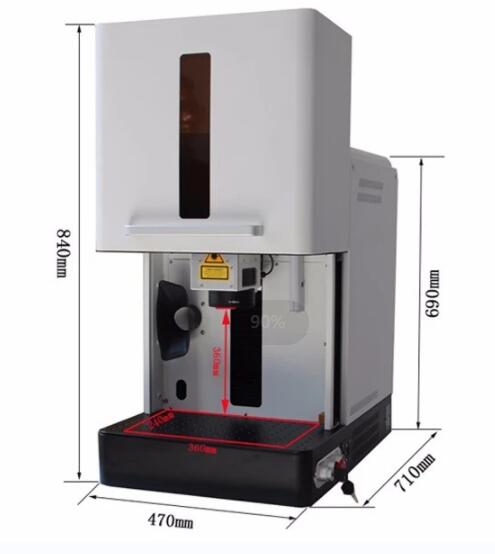

| Dimensiones (L×A×A) |

1180×600×1320 mm (opcional) |

| Peso |

Aproximadamente 150 kg (varía según el modelo) |

| Compatibilidad de Software |

Soporta CorelDRAW, AutoCAD, Photoshop, etc. |

| Durabilidad de la Fuente Láser |

Más de 100,000 horas |

Nota: Los parámetros específicos pueden variar según el modelo y la configuración. Es recomendable confirmar las especificaciones detalladas con el proveedor para asegurarse de que la máquina cumpla con los requisitos específicos.

Ventaja

¿Por Qué la Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora es Imprescindible para Tu Negocio (y Cómo Impulsará Tus Ganancias)

Si estás comprometido con hacer crecer tu negocio y dar el salto al futuro de la fabricación de precisión, entonces necesitas poner atención. La Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora no es solo una herramienta, ¡es un cambio total en las reglas del juego!

Ya sea que manejes un negocio de joyería, trabajes en electrónica o produzcas piezas automotrices, esta máquina compacta y poderosa revolucionará la forma en que operas. Aquí te decimos por qué no puedes esperar más para poner en tus manos esta increíble tecnología.

1. Precisión que Dejará Atrás a tus Competidores 🏆

Vamos a ser realistas: cuando se trata de marcar productos delicados—especialmente en la industria de la joyería—la precisión es clave. La Máquina de Marcado Láser de Fibra Mini es una bestia en cuanto a detalle. Ofrece una precisión inigualable, ya sea que estés marcando joyas de metal, cortando diseños intrincados o grabando mensajes personalizados en metales preciosos.

Esta máquina de marcado láser para joyería asegura que cada marca, cada diseño, sea nítido, claro y perfecto. Y para el corte láser de joyería, obtendrás bordes suaves y limpios que los métodos tradicionales simplemente no pueden igualar.

Imagina poder marcar oro, plata y platino con precisión impecable en cada uso. Esto no es solo precisión; esto es artesanía de otro nivel.

2. Diseño Compacto con Gran Impacto 🛠️

No dejes que el “mini” te engañe—la Máquina de Marcado Láser de Fibra Mini tiene un impacto impresionante a pesar de su diseño compacto. Si tienes poco espacio en tu taller o fábrica, este diseño ahorrador de espacio te permite maximizar tu área de trabajo sin comprometer el rendimiento.

Para negocios en espacios reducidos, como aquellos que operan máquinas de corte láser para joyería, esta es la solución perfecta. Ahora puedes integrar potencia láser de alta gama en tus espacios más pequeños, todo mientras aumentas tu capacidad de producción. Tamaño pequeño, gran impacto.

3. Velocidad, Velocidad, Velocidad – Aumenta tu Producción con Precisión Láser ⚡

El tiempo es dinero—y la Máquina de Marcado Láser de Fibra Mini lo sabe. La velocidad con la que opera es impresionante. Ya sea que estés cortando patrones intrincados en joyas o marcando números de serie en componentes electrónicos, esta máquina no solo es rápida—es eficiente.

Mayor producción significa más productos en menos tiempo, y más productos significan más ventas. En un mundo donde cada segundo cuenta, la capacidad de producir más rápido y con alta calidad en joyería, electrónica o piezas automotrices, es una ventaja clave sobre tus competidores.

4. Sin Límites: Perfecta para Múltiples Materiales y Aplicaciones 🔄

No importa si trabajas con metales, plásticos o cerámica—la Máquina de Marcado Láser de Fibra Mini está diseñada para manejarlo todo. Su versatilidad es lo que la hace tan popular en industrias que van desde el marcado de joyas hasta el grabado de electrónica.

La flexibilidad de esta máquina te permite cambiar entre diferentes materiales y tareas sin problemas. Marca logotipos, números de serie, códigos de barras o incluso diseños personalizados en cualquier material que necesites, sin preocuparte por tiempos de configuración o tener que cambiar de máquina.

Ya sea que trabajes en joyería fina, electrónica o componentes automotrices, esta máquina te brinda la flexibilidad para hacerlo todo.

5. Inversión Rentable con un ROI Impactante 💰

¿Piensas que invertir en una Máquina de Marcado Láser de Fibra Mini es un gran paso? Piensa de nuevo. Esta máquina no es solo un activo—es una inversión. Su bajo mantenimiento y alta durabilidad significan que ahorrarás dinero en reparaciones, tiempos de inactividad y consumibles. No tendrás que gastar una fortuna en tinta o gas, ni preocuparte por problemas constantes de mantenimiento.

De hecho, esta máquina de marcado láser se pagará sola en muy poco tiempo. Más eficiencia, menos errores y mayor producción significan mayores ganancias. Si diriges un negocio de joyería, imagina cuánto tiempo ahorrarás al no tener que grabar o cortar manualmente diseños intrincados. Con esta máquina, mejorarás tanto tu producción como la calidad.

6. Fabricación Ecológica y Sostenible 🌱

¿Quieres reducir tu huella de carbono sin perder resultados de primer nivel? La Máquina de Marcado Láser de Fibra Mini es energéticamente eficiente y no usa consumibles. Esto significa sin químicos dañinos, sin residuos tóxicos y sin consumo excesivo de energía.

Si deseas tener un negocio más sostenible—ya sea en joyería o en cualquier otro tipo de marcado de alta precisión—esta máquina te ayuda a lograrlo. Es mejor para el planeta y mejor para tu rentabilidad.

¿Por qué esperar? Invierte hoy en el futuro de tu negocio! 🚀

Ahora que ves las ventajas, probablemente estés pensando, “¿Cómo puedo poner mis manos en esta Máquina de Marcado Láser de Fibra Mini lo antes posible?”

Ya sea que marques joyería, electrónica o piezas automotrices, esta máquina te ofrece todo lo que necesitas: velocidad, precisión, versatilidad y rentabilidad.

Es hora de dejar atrás el equipo anticuado y llevar tu negocio al siguiente nivel. No dejes que tus competidores te superen. Obtén la ventaja que necesitas—actualízate a la Máquina de Marcado Láser de Fibra Mini hoy mismo.

¿Listo para ver cómo funciona? ¡Haz tu pedido ahora y empieza a marcar con precisión y velocidad!

Aplicación

Aplicaciones de la Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora

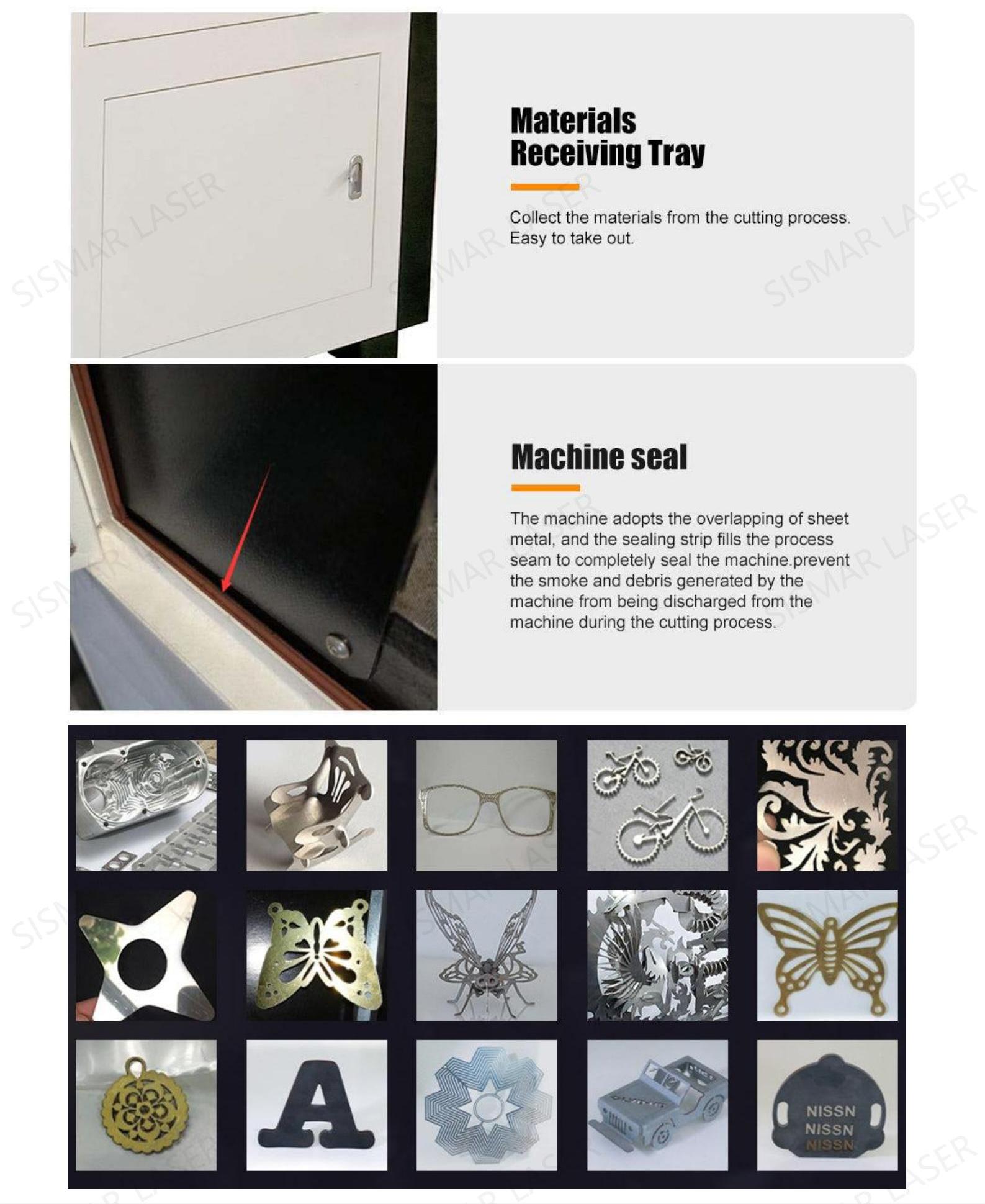

La Máquina de Marcado Láser de Fibra Mini con Cubierta Protectora es una herramienta versátil que puede usarse en una amplia variedad de industrias. Su precisión, velocidad y diseño compacto la convierten en la opción ideal para tareas que van desde el corte láser de joyería hasta el marcado de electrónica, grabado automotriz y mucho más. Ya sea que trabajes en diseños personalizados de alta gama o en producción en masa, esta máquina está diseñada para cumplir con todas tus necesidades. A continuación, exploramos algunas de las principales aplicaciones en las que esta poderosa máquina puede marcar la diferencia.

1. Industria de la Joyería: Corte y Grabado Láser de Precisión 💍

La Máquina de Marcado Láser de Fibra Mini es un cambio de juego en la industria de la joyería. Ofrece precisión excepcional a la hora de cortar joyas con láser y grabar diseños intrincados en metales preciosos como oro, plata y platino.

- Grabado Láser: Ideal para marcar números de serie, logotipos de marcas y mensajes personalizados en joyería fina.

- Corte Láser: Perfecta para cortar diseños delicados en piezas pequeñas de joyería con bordes suaves y limpios.

- Personalización: Añade toques únicos a anillos, collares, pulseras y otras piezas grabando texto o diseños personalizados.

Para los joyeros, esta máquina ofrece la capacidad de crear diseños altamente detallados y consistentes mientras se minimiza el riesgo de errores. Es la herramienta perfecta tanto para diseños personalizados como para producción en masa.

2. Electrónica: Marcado de Componentes con Alta Precisión ⚙️

En la industria electrónica, la Máquina de Marcado Láser de Fibra Mini sobresale en el marcado de detalles pequeños e intrincados en componentes como placas de circuitos, condensadores y microchips.

- Marcado de Componentes: Marca fácilmente números de serie, códigos de barras y logotipos en dispositivos electrónicos.

- Marcado de Códigos QR: Ideal para grabar códigos QR en dispositivos como teléfonos, laptops y gadgets.

- Trazabilidad: Asegura que cada componente pueda rastrearse hasta su origen, mejorando la calidad del producto y el cumplimiento de normativas.

La alta precisión de esta máquina asegura que incluso los componentes más pequeños sean marcados de manera clara, sin distorsiones, lo que la convierte en una herramienta invaluable para los fabricantes de electrónica.

3. Industria Automotriz: Marcado Duradero y Confiable 🚗

La Máquina de Marcado Láser de Fibra Mini también es ideal para la industria automotriz, donde el marcado duradero y de alta calidad es esencial.

- Identificación de Piezas: Marca piezas automotrices como componentes de motores, chasis y cajas de cambios con números de serie o logotipos de marcas.

- Marcado Duradero: La tecnología láser de fibra crea marcas que son resistentes al desgaste, la corrosión y las altas temperaturas.

- Marcado de Metales: Ideal para marcar piezas metálicas como pastillas de freno, bloques de motor y ruedas.

Esta máquina garantiza que los componentes automotrices sean marcados con precisión y que las marcas perduren durante toda la vida útil del vehículo, incluso bajo condiciones extremas.

4. Herramientas y Maquinaria: Grabado de Alta Velocidad para Herramientas Industriales 🛠️

Para los fabricantes que trabajan en los sectores de herramientas y maquinaria, la Máquina de Marcado Láser de Fibra Mini es perfecta para grabar y marcar herramientas industriales.

- Marcado de Herramientas: Marca equipos como llaves, destornilladores y piezas de máquinas con números de serie, logotipos o certificaciones de seguridad.

- Marcas Duraderas: Las marcas son resistentes al desgaste, asegurando que permanezcan legibles incluso después de un uso prolongado en entornos difíciles.

La capacidad de esta máquina para marcar piezas de alta durabilidad la convierte en una herramienta clave para cualquier fabricante en el sector de equipos industriales.

5. Industria Médica: Marcado Preciso para Dispositivos Médicos 🏥

En la industria médica, la precisión es crítica, especialmente cuando se trata de marcar dispositivos médicos que requieren trazabilidad y el cumplimiento de normativas regulatorias.

- Marcado de Dispositivos Médicos: Ideal para marcar instrumentos quirúrgicos, herramientas médicas e implantes con números de serie, números de parte y códigos de barras.

- Alta Precisión: La Máquina de Marcado Láser de Fibra Mini proporciona la precisión necesaria para partes pequeñas y delicadas, asegurando marcas claras que cumplen con estrictas regulaciones.

Ya sea que estés marcando cuchillos quirúrgicos o dispositivos implantables, esta máquina está diseñada para cumplir con los más altos estándares de precisión y fiabilidad.

6. Bienes de Consumo: Branding Rápido y Preciso 📦

Para los fabricantes de bienes de consumo, esta máquina de marcado láser ofrece soluciones rápidas, eficientes y precisas. Ya sea que estés marcando tus productos o grabando un logotipo, esta máquina hará que tus productos se destaquen en el mercado.

- Branding: Marca el empaquetado de productos, etiquetas y productos con el logotipo de tu empresa o un número de serie único.

- Producción en Masa: Las capacidades de alta velocidad aseguran que incluso grandes volúmenes de productos se puedan marcar rápidamente sin comprometer la calidad.

Ya sea que estés marcando empaques de cosméticos, equipos deportivos o gadgets, la Máquina de Marcado Láser de Fibra Mini está lista para la tarea.

7. Aeroespacial: Marcado Confiable para Componentes Críticos ✈️

En el sector aeroespacial, donde la fiabilidad y la seguridad son primordiales, la Máquina de Marcado Láser de Fibra Mini asegura que los componentes críticos estén marcados de manera clara y permanente.

- Identificación de Componentes: Marca partes de aeronaves, como componentes de motores, frenos y cables, con números de identificación únicos o códigos de parte.

- Cumplimiento Regulatorio: Asegura que todas las partes cumplan con las normativas de la industria mediante el marcado preciso de cada componente.

La precisión de esta máquina la convierte en la opción ideal para industrias de alto riesgo como la aeroespacial, donde el fracaso no es una opción.

¿Por Qué la Máquina de Marcado Láser de Fibra Mini es la Elección Perfecta para Ti?

Desde joyería hasta electrónica y más allá, la Máquina de Marcado Láser de Fibra Mini está diseñada para manejar una amplia variedad de industrias. Ya sea que estés grabando números de serie en electrónica, cortando diseños intrincados en joyería o marcando partes automotrices, esta máquina aporta velocidad, precisión y versatilidad a cada proyecto.

Invertir en esta máquina significa que obtendrás una herramienta capaz de manejar todas tus necesidades de marcado con facilidad, sin importar la industria. ¿Estás listo para elevar tus procesos de fabricación? La Máquina de Marcado Láser de Fibra Mini es la adición perfecta para cualquier negocio que quiera estar a la vanguardia.

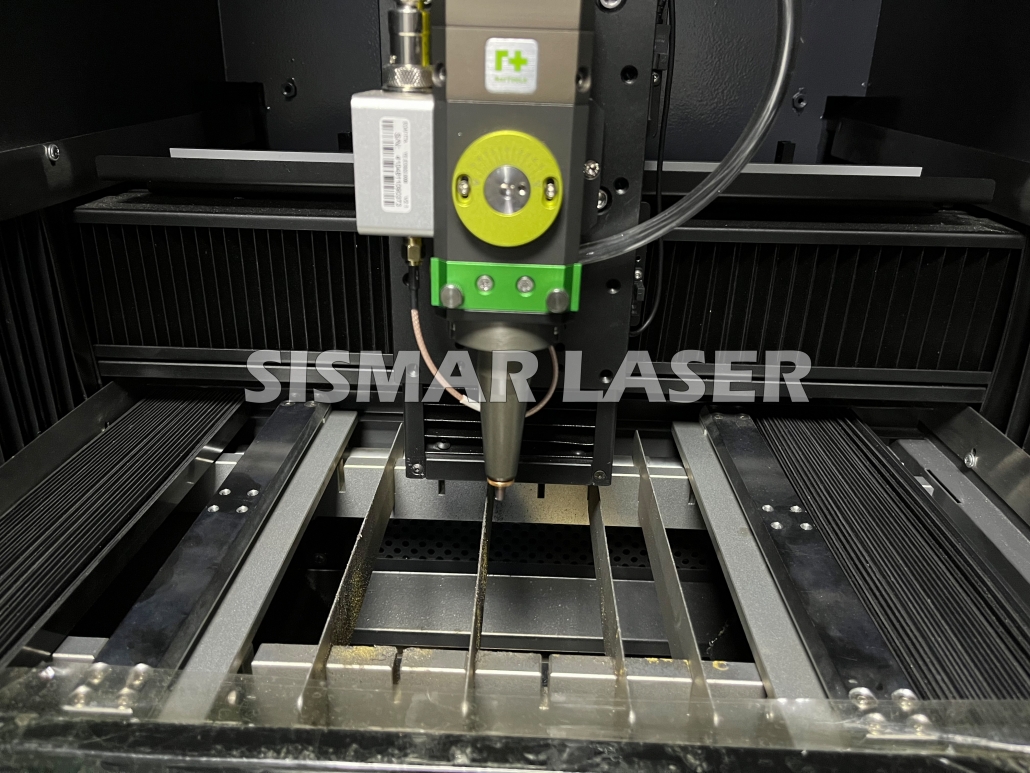

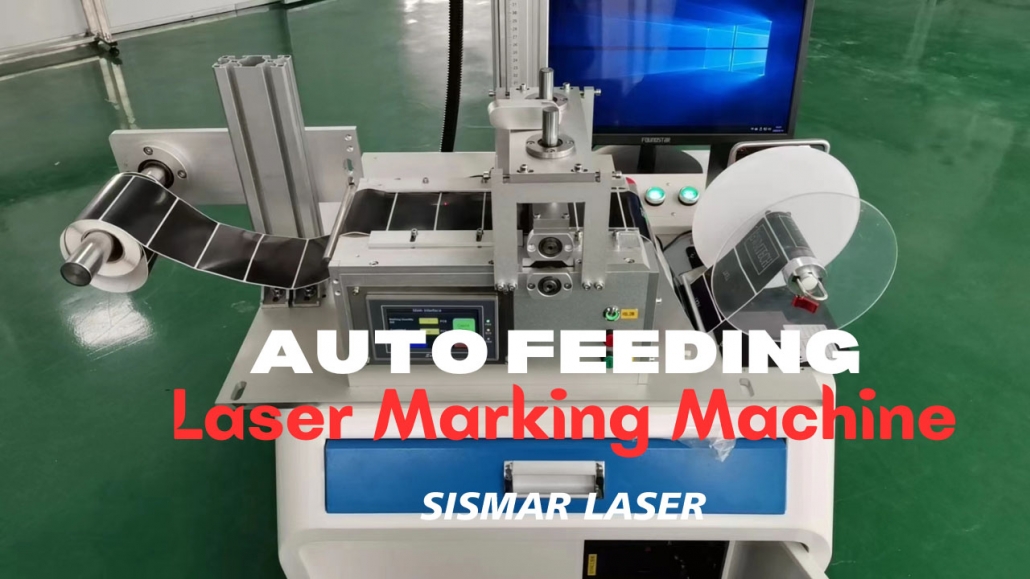

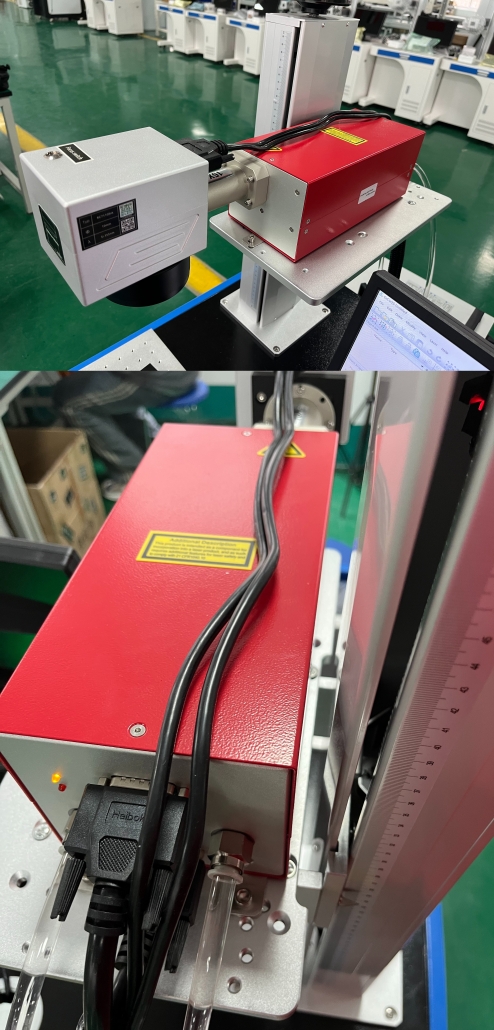

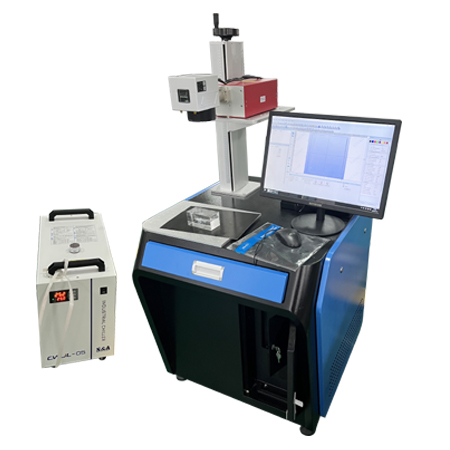

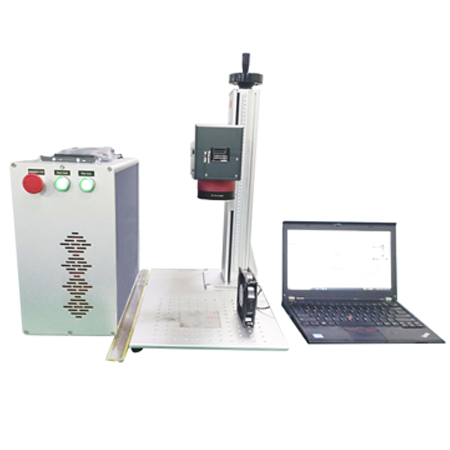

Fotos Detalladas