High-Precision UV Laser Seashell & Mother of Pearl Cutting Machine

Precision UV Laser Cutting for Fine Seashell Jewelry

UV Laser Cutting for Seashell Jewelry & Crafts

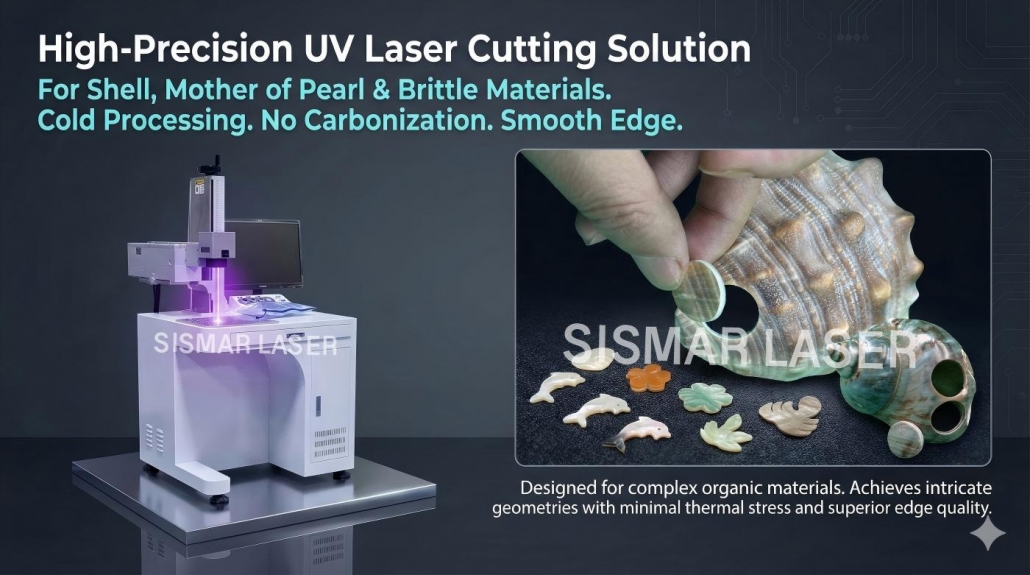

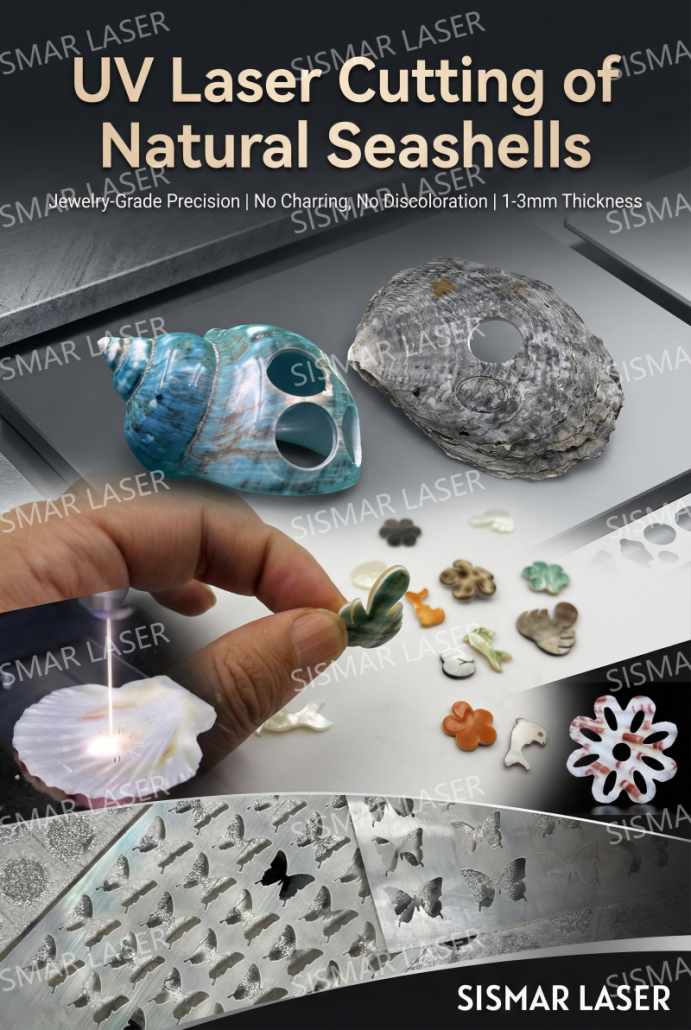

Designed for jewelry and craft makers, this UV laser cutting machine delivers clean, precise cutting on natural seashell without burning or edge damage. The 355 nm cold-processing UV laser preserves natural color and fine detail, making it ideal for earrings, pendants, inlays, and decorative shell pieces. Perfect for studios and small-scale production demanding consistency and refined finish.

UV Laser Marking & Cutting Machine for Sea Shells

Product Overview

Ever spent hours trying to cut Mother of Pearl, abalone, or exotic shells, only to end up with chipped edges, burnt surfaces, or wasted material? Traditional CO₂ or fiber lasers just don’t cut it, and mechanical routers leave you sanding for hours.

The UV Laser Seashell Cutting Machine changes all that. Using 355 nm ultraviolet laser technology, it delivers cold, micron-level precision cuts, preserving your shells’ natural color and structure. With a 100 × 100 mm working area, this machine is perfect for high-end jewelry, inlays, and custom designs—whether in small workshops or industrial production.

Clean edges, zero burning, and precise cuts—finally, a laser that works the way you need it to.

Why UV Laser is the Only Choice

Many makers ask: “Can’t I just use my CO₂ or Fiber laser?”

Here’s the truth: UV laser is the only reliable solution for delicate shells.

Cold Processing: Cuts at a molecular level without heat

Pristine Edges: Smooth, chip-free, no post-processing needed

Ultra-Fine Precision: Micron-level accuracy for intricate jewelry patterns

Maximized Material Yield: Complex nested designs save valuable material

| Feature | UV Laser | CO₂ Laser | Fiber Laser |

|---|---|---|---|

| Cutting Type | Cold / Molecular | Thermal / Burns | Thermal / Cracks |

| Edge Quality | Smooth & pristine | Burnt & yellowed | Rough & fractured |

| Precision | Micron-level | Wider kerf | Too aggressive |

| Material Impact | Preserves structure | Burns & smells | Cracks & chips |

Bottom line: If you want perfect shell edges every time, UV laser is the only way to go.

Core Advantages

Zero Thermal Impact: No warping, burning, or carbonization

Jewelry-Grade Precision: High-speed galvanometers + f-theta lens achieve ±0.01 mm tolerance

Narrow Kerf: Save raw material, perfect for intricate nested patterns

Organic-Friendly Energy: Prevents delamination or edge-chipping on multi-layered shells

Repeatable & Reliable: Ideal for both single-piece craftsmanship and batch production

Applications

High-End Jewelry: Rings, pendants, earrings, luxury watch inlays

Musical Instruments: Abalone or shell fretboard inlays

Luxury Home Decor: Shell tiles, furniture inlays, premium gifts

Fashion Accessories: Buttons, brand logos, decorative accents

If you can draw it, you can cut it. Lace patterns, logos, or micro details—no problem.

Who Benefits Most

Jewelry Makers & Brands:

Cut scrap rates from 20–30% to nearly zero

Eliminate hours of manual sanding and cleaning

Create designs impossible with CNC routers

Distributors & Agents:

Offer a blue ocean product few competitors provide

High-margin, premium-positioning solution

Reliable, low-maintenance machine built for 24/7 operation

Technical Specifications

| Item | Specification |

|---|---|

| Laser Power | 10W / 15W (Optional) |

| Wavelength | 355 nm (Ultraviolet) |

| Work Area | 100 × 100 mm (Standard) |

| Z-Axis Travel | Motorized, 120 mm |

| Positioning Accuracy | ±0.01 mm |

| Repeatability | ±0.005 mm |

| Maximum Cutting Speed | Up to 300 mm/s |

| Minimum Spot Size | ≤ 15 μm |

| Cooling System | Industrial Water Chiller |

| Supported File Formats | AI, DXF, PLT, BMP, JPG |

| Software Compatibility | AutoCAD, CorelDRAW, Adobe Illustrator |

Why This Machine is a Smart Investment

Reduce Scrap & Waste: Up to 99% usable material

Limitless Design Freedom: Cut intricate patterns and logos

Save Time & Labor: Edges are ready to assemble, polish, or inlay

Reliable ROI: A premium product for premium markets

Call to Action

Stop wasting time and valuable shell material. Upgrade your shell cutting process now.

Two UV Laser Cutting Models for Seashell

We offer two models of UV laser cutting machines designed specifically for natural seashell and delicate materials: Mini Model and Pedestal Model. Each is tailored to different production needs, allowing you to choose the machine that best fits your workshop, design requirements, and volume.

Summary:

Choose Mini Model for flexibility and space-saving precision, perfect for small-scale jewelry and craft projects. Opt for Pedestal Model if you need a stable machine for larger pieces or higher-volume production. Both machines deliver clean, precise, and consistent results, preserving the natural beauty of shells while maximizing efficiency.

Ready to find the perfect fit for your workshop? Contact us today to get a personalized recommendation or request a quote.

FAQ – UV Laser Cutting Seashell (Table Version)

| Question | Answer / Key Value Points |

|---|---|

| 1. What materials can I cut? | Natural seashell, MOP, abalone, PU films, leather, thin plastics, wood veneer, paper. Ideal for intricate jewelry inlays, earrings, pendants, and craft pieces. |

| 2. How thick can the shell be for cutting? | Up to 3mm for natural shell; up to 0.5 mm for soft polymers. Cuts delicate layers precisely without chipping. |

| 3. Will edges burn, chip, or discolor? | No. 355 nm UV “cold laser” preserves natural colors. Edges remain smooth and white—perfect for luxury jewelry and artisan crafts. |

| 4. Cutting precision | Accuracy: ±0.01 mm; Repeatability: ±0.002 mm; Minimum line width: 0.03 mm. Micron-level detail for complex designs and lace-like inlays. |

| 5. Software & file compatibility | AI, DXF, PLT, BMP, JPG. Works with AutoCAD, CorelDRAW, Illustrator. Seamlessly turn digital designs into flawless physical pieces. |

| 6. Mini vs Pedestal models | Mini: Compact, flexible, 100 × 100 mm, perfect for small workshops/prototypes/artisan jewelry. Pedestal: Stable, 110 × 110 mm, ideal for larger components, higher-volume production, professional studios. |

| 7. Cutting speed | Adjustable 50–300 mm/s depending on material and thickness. Fast, efficient cutting without compromising quality. |

| 8. Training provided? | Yes, 1–2 days remote or on-site. Covers software, material optimization, focus alignment, multi-pass cutting, troubleshooting. Enables quick, high-quality production. |

| 9. Maintenance | Daily: Check lenses, cooling, grounding, filters. Weekly: Clean optical path, inspect galvo, backup software. Monthly: Inspect chiller, laser power, platform flatness. Ensures consistent precision and reliability. |

| 10. Why UV laser vs CO₂ / fiber lasers? | Cuts at molecular level (“cold processing”). Preserves delicate shells, intricate patterns, and natural shine without burning or chipping. Perfect for premium jewelry and craftwork. |

High-Precision UV Laser Cutter for Sea Shells – Live Demo

Request a Quote for UV Laser Seashell Cutting Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Create Flawless Jewelry & Crafts with UV Laser Seashell CuttingFebruary 10, 2026 - 4:14 am

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am