High-Speed UV Flying Laser Marking for PP Hollow Sheets

High-Speed UV Flying Laser Marking for PP Hollow Sheets

Boost your PP hollow sheet production with our High-Speed UV Flying Laser Marker. Say goodbye to slow inkjet printing, messy labels, and frequent downtime. This UV laser marking machine delivers fast, precise, and permanent marks directly on PP hollow sheets—on the fly.

With zero consumables and high-speed automated operation, our UV laser marking system ensures clear, durable, and high-contrast logos, QR codes, barcodes, and serial numbers. Perfect for industrial production lines, it dramatically increases efficiency, reduces labor costs, and keeps your PP hollow sheet products looking professional and traceable.

Upgrade your production today with a reliable, high-speed UV flying laser marking solution!

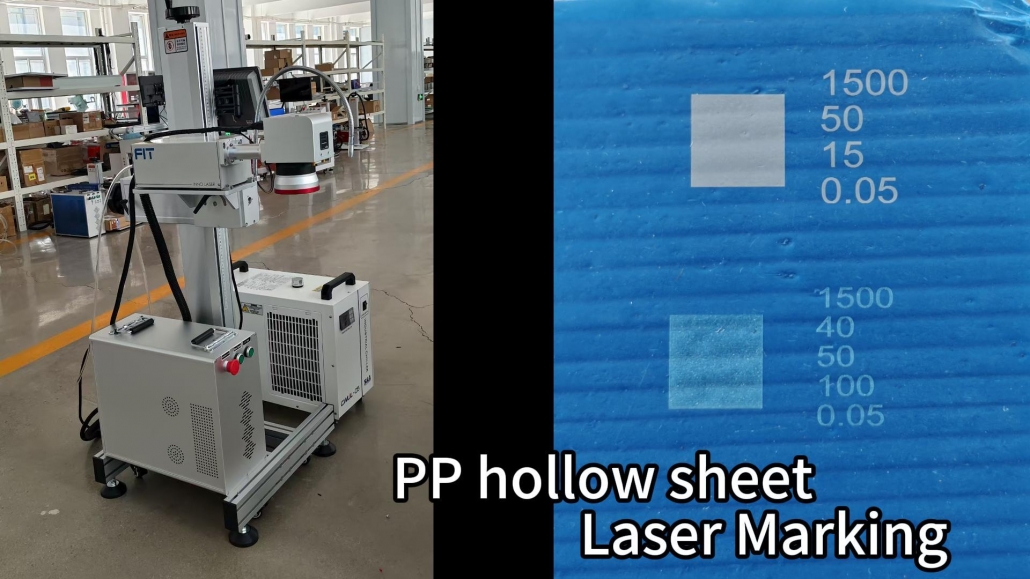

Photos of the Flying Laser Marking Machine Online

High-Speed UV Flying Laser Marking for PP Hollow Sheet Production Lines

Stop Wasting Time and Materials—Boost Your PP Hollow Sheet Production Today

Tired of slow, messy, or unreliable marking on your PP hollow sheets? Inkjet printers blur, wear out, and cost a fortune in consumables. Manual marking? Slow, inconsistent, and error-prone. Your PP Hollow Sheet Production Line shouldn’t be held back by outdated methods.

Enter the High-Speed UV Flying Laser Marking system—designed specifically for PP Hollow Sheet Production Lines. This isn’t just another machine; it’s a productivity upgrade. On-the-fly, high-speed laser marking ensures perfect, permanent marks—every single time—without slowing down your line.

Why This Works (and Why You’ll Love It)

Blazing Fast Production: Mark PP hollow sheets at up to 200m/min while they move along your line. No stops. No bottlenecks. Just smooth, continuous production.

Crisp, Permanent, Fade-Resistant Marks: Fine lines down to 0.1mm. QR codes, barcodes, logos—etched perfectly with UV precision. Durable against wear, chemicals, and time. Your products look professional and traceable.

Plug-and-Play Automation: Compact, user-friendly, and easy to integrate. Set it up once, and let the UV flying laser marking system handle the rest. Fewer errors, less labor, more output.

Eco-Friendly & Cost-Saving: No inks, no solvents, no wasted materials. This laser marking PP hollow sheet solution saves money while keeping your line clean and green.

Parameter Sheet: Engineered for Performance

| Parameter | Specification | Engineer’s Insight |

|---|---|---|

| Laser Type | UV Laser (355nm) | Cold processing avoids heat damage, ideal for PP hollow sheets |

| Laser Power | 3W / 5W / 10W (Optional) | Higher power = faster laser marking PP hollow sheet |

| Marking Method | On-the-fly Marking | Designed for continuous, high-speed PP Hollow Sheet Production Lines |

| Max. Marking Speed | Up to 200 m/min | Keeps your production line running at peak efficiency |

| Marking Area | 70x70mm – 300x300mm | Customizable for all PP hollow sheet sizes |

| Min. Line Width | ≤0.1mm | Perfect for fine text, detailed patterns, and QR codes |

| Cooling Method | Air Cooling | Simple, reliable, no external water system needed |

| Supported Formats | PLT, DXF, AI, DST, BMP, JPG, PNG | Easy integration into existing workflows |

This parameter sheet shows exactly why our High-Speed UV Flying Laser Marking system outperforms traditional methods.

Applications: High-Speed UV Flying Laser Marking in Action

Logistics & Packaging: Mark batch numbers, QR codes, and tracking info on reusable PP hollow sheet boxes.

Construction & Building Materials: Add specifications and brand logos to PP acoustic panels and protective sheets.

Advertising & Display: Create clear graphics, text, and signs on PP hollow sheets.

Why Partner with Us?

Experienced Engineers: Our team ensures seamless integration of High-Speed UV Flying Laser Marking into your PP Hollow Sheet Production Line.

Custom Solutions: Tailored laser marking PP hollow sheet systems to fit your production line perfectly.

Full Support: Free sample testing, installation, training, and ongoing technical assistance.

See It for Yourself

Send us your PP hollow sheet samples. Experience firsthand how High-Speed UV Flying Laser Marking transforms your PP Hollow Sheet Production Line—faster, cleaner, and more efficient than ever.

CTA: Get Your Free Sample Test Today → Watch Your Production Take Off

Comparison of PP Hollow Sheet Marking Methods vs. UV Laser Marking

| Marking Method | Advantages | Disadvantages |

|---|---|---|

| Inkjet Printing | – Low initial cost – Easy to implement | – Ink may smudge or fade – Low resolution, especially on textured surfaces – Requires frequent maintenance and cleaning |

| Pad Printing | – Can handle complex shapes – Moderate cost | – Slow for large volumes – Limited durability – Ink may not adhere well to smooth PP surfaces |

| Hot Stamping / Embossing | – Durable marks – Can create tactile effects | – Slow process – Requires molds or plates – Not suitable for continuous production lines |

| UV Laser Marking | – High-speed and non-contact – Precise, high-resolution marks – Permanent and chemical-free – Works on smooth and textured surfaces – Minimal maintenance | – Higher initial investment – Requires trained operators |

Summary:

UV laser marking is the most reliable, precise, and maintenance-free method for high-speed PP hollow sheet production lines. It overcomes the smudging, fading, and low-resolution issues of ink-based methods while enabling permanent, high-quality marks suitable for large-scale industrial use.

FAQ – UV Laser Marking for PP Hollow Sheets

1. What is UV laser marking?

UV laser marking is a high-precision, non-contact method that uses ultraviolet light to permanently mark or engrave PP hollow sheets without inks or chemicals.

2. How does it compare to traditional inkjet or pad printing?

Unlike ink-based methods, UV laser marking produces permanent, high-resolution marks that won’t smudge, fade, or require cleaning. It’s ideal for high-speed production lines.

3. Can it mark textured or curved surfaces?

Yes. UV lasers can mark flat, curved, or textured PP surfaces with consistent quality and clarity.

4. Is it safe for production lines?

Yes. UV laser systems are non-contact, chemical-free, and produce minimal heat, so they won’t damage your PP sheets. Proper safety enclosures are recommended for operators.

5. What types of marks can it create?

UV lasers can create logos, text, QR codes, barcodes, serial numbers, or custom patterns with precise detail.

6. How fast is UV laser marking?

High-speed UV flying laser systems can match the throughput of automated PP hollow sheet lines, significantly faster than pad printing or hot stamping.

7. What is the maintenance requirement?

UV laser systems require minimal maintenance. There’s no ink refilling, nozzle cleaning, or plate replacement—just routine checks and lens cleaning.

8. Is it cost-effective?

While the initial investment is higher than ink-based methods, UV laser marking reduces long-term costs by eliminating consumables, maintenance, and rework due to poor-quality marks.

Videos of Flying Laser Marking Machine

Request a Quote for a Online Flying Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am

- EZCAD common errorMarch 18, 2025 - 2:09 am