Máquina de Marcado Láser de Alta Velocidad en Tiempo Real

February 17, 2025 /0 Comments/in Language /by linda

Máquina de Marcado Láser Volante en Línea

Máquina de Marcado Láser Voladora: La Solución Definitiva de Alta Velocidad para un Marcado Preciso

Si estás buscando una máquina de marcado láser que pueda seguir el ritmo de tus demandas de producción de alta velocidad, la Máquina de Marcado Láser Voladora es exactamente lo que necesitas. No es una máquina cualquiera; está diseñada para ofrecer marcas consistentes y de alta calidad a velocidades vertiginosas, todo mientras garantiza que tus materiales se mantengan intactos y tu flujo de trabajo sea eficiente.

¿Qué la hace destacar? Para empezar, la máquina opera de manera continua, sin interrupciones. Esto significa que, ya sea que estés trabajando con electrónica, piezas automotrices o empaques, este sistema puede manejarlo todo sin perder el ritmo. La mesa de trabajo dinámica se adapta a diversos materiales como metales, plásticos, y más, brindándote una versatilidad incomparable. Además, la tecnología láser de alta precisión asegura que cada marca sea nítida, clara y duradera.

Imagina esto: producción más rápida, marcas de mejor calidad y menos retrasos. Es la eficiencia que impulsa tus ganancias y te mantiene por delante de la competencia. 🚀

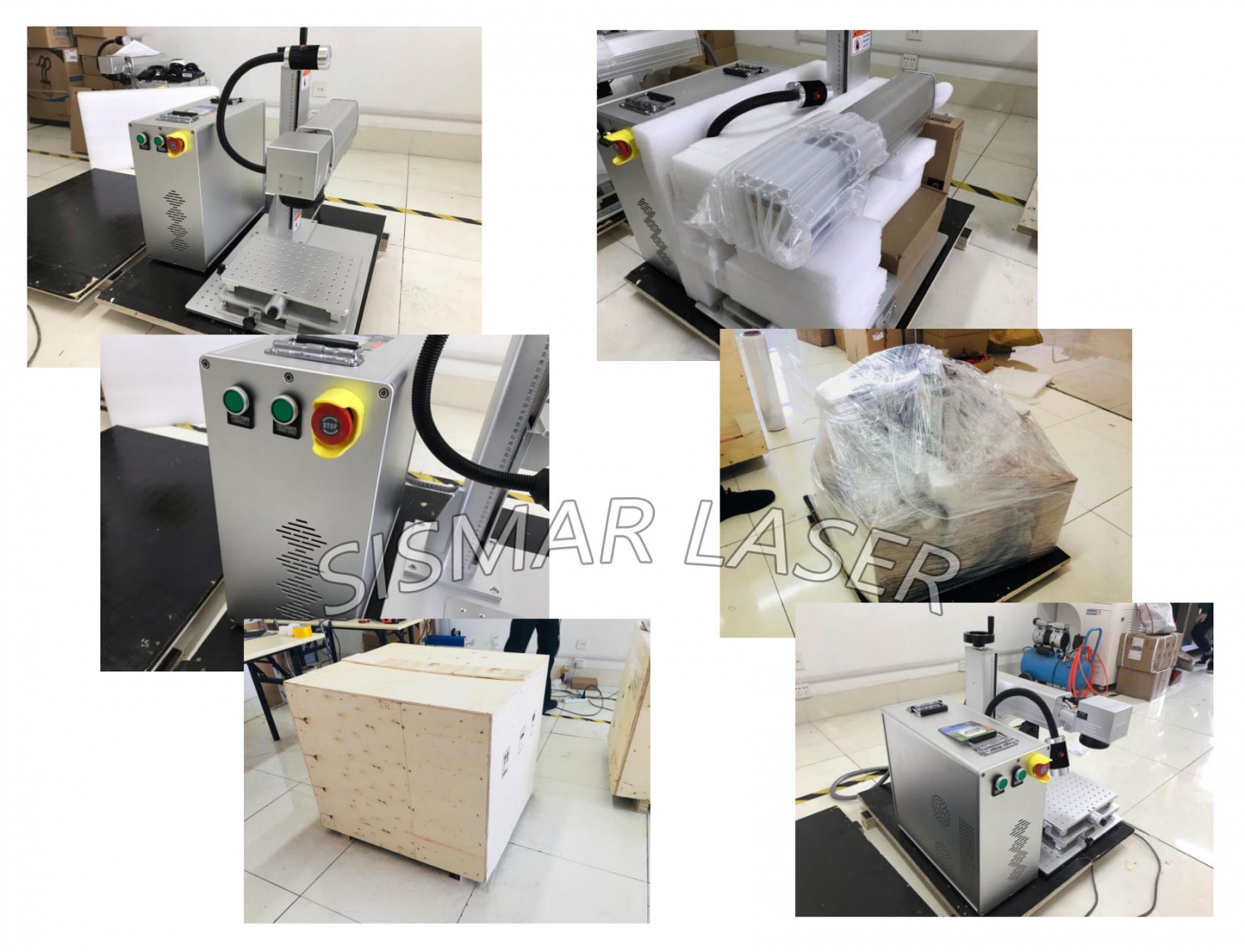

Fotos de la Máquina de Marcado Láser Volante en Línea

Máquina de Marcado Láser Voladora: La Solución Definitiva para un Marcado Rápido y Preciso ✨

¿Estás buscando un marcado rápido y preciso que mantenga tu producción en marcha sin interrupciones? La Máquina de Marcado Láser Voladora es la tecnología innovadora que has estado esperando. Esta poderosa máquina está diseñada para marcar diversos materiales como metales, plásticos y composites con una precisión y velocidad inigualables, lo que la hace ideal para industrias como electrónica, automotriz y empaques.

1️⃣. ¿Qué es la Máquina de Marcado Láser Voladora? 🔍

La Máquina de Marcado Láser Voladora es un sistema láser de última generación diseñado para marcar productos de forma continua mientras pasan por la línea de producción. A diferencia de las máquinas láser tradicionales que requieren piezas de trabajo estacionarias, este sistema láser volador trabaja sobre un objetivo dinámico y en movimiento, convirtiéndola en la opción perfecta para la manufactura de alta velocidad.

2️⃣. Características y Beneficios Clave:

| Características | Descripción |

|---|---|

| 2.1 Operación Continua Sin Interrupciones ⏩ | La Máquina de Marcado Láser Voladora sigue funcionando a máxima velocidad, marcando productos en tiempo real a medida que pasan por el sistema. Esta operación continua elimina el tiempo de inactividad, convirtiéndola en la solución ideal para líneas de producción de alta velocidad. |

| 2.2 Dinámica y Flexible 🌍 | Ya sea que estés marcando componentes pequeños y detallados o piezas grandes, la Máquina de Marcado Láser Voladora se adapta a una variedad de materiales y tamaños gracias a su mesa de trabajo ajustable y su avanzado cabezal láser. |

| 2.3 Marcado Láser de Alta Precisión 🎯 | Experimenta una precisión láser superior. Desde pequeños números de serie hasta logos detallados, la Máquina de Marcado Láser Voladora crea marcas nítidas, claras y duraderas, perfectas para productos que requieren grabado en alta definición. |

| 2.4 Marcas Duraderas y Resistentes 🌟 | Las marcas producidas por la Máquina de Marcado Láser Voladora son resistentes al desgaste, asegurando que tus marcas no se desvanezcan con el tiempo. Esto es ideal para productos que enfrentan condiciones ambientales exigentes. |

| 2.5 Mayor Productividad 📈 | Al usar la Máquina de Marcado Láser Voladora, puedes aumentar significativamente tu salida de producción. Las velocidades de marcado más rápidas significan que más productos se procesan en menos tiempo, aumentando la eficiencia general y reduciendo los costos operativos. |

3️⃣. ¿Por qué elegir la Máquina de Marcado Láser Voladora? 🤔

En industrias donde tanto la velocidad como la precisión son críticas, la Máquina de Marcado Láser Voladora ofrece lo mejor de ambos mundos. Con su tecnología avanzada, te ayuda a lograr marcas perfectas a mayores velocidades, todo mientras mantiene tu producción funcionando sin contratiempos.

Desbloquea la Eficiencia y Precisión con la Máquina de Marcado Láser Voladora 🚀

Si has estado buscando una máquina de marcado láser de alta velocidad y precisión, la Máquina de Marcado Láser Voladora es exactamente lo que necesitas. Ya sea que trabajes en manufactura, electrónica, automotriz, o incluso en joyería, esta máquina está diseñada para manejar una variedad de materiales y ofrecer resultados consistentes de alta calidad.

¿Pero qué es lo que hace que esta máquina se destaque? 🤔

Vamos a desglosar los parámetros clave y por qué son importantes para ti:

| Parámetro | Descripción | Por qué es importante |

|---|---|---|

| Potencia del Láser | 20W, 30W, 50W | Determina la velocidad y la profundidad del marcado. Mayor potencia permite un procesamiento más rápido y el marcado de materiales más duros. |

| Área de Marcado | 110mm x 110mm, 150mm x 150mm | Un área de marcado más grande permite marcar múltiples artículos a la vez o piezas más grandes, mejorando la flexibilidad de producción. |

| Velocidad de Marcado | 7000 mm/s | Velocidades de marcado más rápidas aumentan la productividad, permitiéndote producir más unidades por hora. |

| Tipo de Láser | Láser de Fibra | Ofrece alta precisión y puede manejar diversos materiales (metales, plásticos, cerámica) con mínimo mantenimiento. |

| Resolución | 0.001mm | Ofrece detalles ultra-finos, esenciales para marcas nítidas y claras como números de serie o diseños complejos. |

| Sistema de Enfriamiento | Refrigeración por aire | Previene el sobrecalentamiento durante el uso prolongado, asegurando un rendimiento constante sin necesidad de sistemas de refrigeración adicionales. |

| Calidad del Haz | <1.5M² | Asegura precisión y claridad, produciendo marcas de alta calidad y detalles finos. |

| Dimensiones | 800mm x 600mm x 1150mm | Su tamaño compacto facilita la integración en configuraciones existentes, manteniendo la eficiencia en el uso del espacio. |

| Peso | Aproximadamente 70kg | Una máquina más pesada ofrece estabilidad durante la operación, reduciendo las vibraciones para obtener resultados consistentes. |

| Voltaje | 220V ±10% | El requisito de voltaje estándar asegura una integración sin problemas con la mayoría de las instalaciones eléctricas existentes. |

Las Ventajas de la Máquina de Marcado Láser Voladora 🚀

Si estás buscando aumentar la eficiencia y la precisión en tu proceso de fabricación, la Máquina de Marcado Láser Voladora podría ser el cambio radical que necesitas. Aquí te explicamos por qué deberías considerarla:

| Ventaja | Descripción | Caso Ejemplo |

|---|---|---|

| 1. Velocidad Relámpago ⚡ | La Máquina de Marcado Láser Voladora opera a máxima velocidad, proporcionando marcado continuo en tiempo real, manteniendo tu línea de producción en movimiento sin retrasos. | Un importante fabricante de automóviles utilizó la máquina para marcar los números VIN en las piezas de automóviles mientras se movían por la línea de producción, cumpliendo con plazos ajustados sin sacrificar calidad. |

| 2. Precisión Inigualable 🎯 | Ofrece precisión milimétrica, asegurando marcas nítidas, limpias y consistentes. Ideal para una variedad de materiales como metales, plásticos y más. | Un fabricante de joyas grabó logotipos detallados en anillos y pulseras, manteniendo la artesanía sin comprometer la superficie de las piezas. |

| 3. Sin Contacto, Sin Problemas 🚫 | El proceso de marcado sin contacto significa sin riesgo de dañar superficies delicadas, logrando resultados duraderos sin tocar físicamente el material. | Una empresa de electrónica marcó números de serie en delicadas placas de circuito sin arriesgarse a dañar componentes sensibles. |

| 4. Bajo Mantenimiento, Alta Eficiencia ⚙️ | Requiere mínimo mantenimiento sin consumibles como tinta o productos químicos, lo que ofrece más tiempo operativo y menos reparaciones. | Un fabricante de dispositivos médicos experimentó una disminución en los costos de mantenimiento y un aumento en la eficiencia de producción al utilizar la máquina para componentes de alta precisión. |

| 5. Integración Perfecta con la Automatización 🔄 | Se integra perfectamente en líneas de producción automatizadas, reduciendo la intervención manual y garantizando una operación fluida. | Una empresa de empaques integró la máquina en su línea automatizada para marcar las fechas de caducidad en productos alimenticios, aumentando la productividad sin interrumpir el proceso de empaque. |

| 6. Ecológica 🌍 | Funciona de manera limpia, sin generar desperdicios, convirtiéndola en una solución ecológica para empresas que buscan reducir su huella ambiental. | Una marca de moda sostenible utilizó la máquina para grabar diseños personalizados en ropa ecológica, eliminando los tintes a base de productos químicos y mejorando el atractivo del producto. |

Aplicaciones de la Máquina de Marcado Láser Voladora 🚀

La versatilidad de la Máquina de Marcado Láser Voladora la convierte en una solución altamente demandada en diversas industrias. Ya sea que trabajes con materiales complejos o necesites marcados de alta velocidad y alta calidad, esta tecnología puede mejorar significativamente la eficiencia de producción y la calidad del producto. Aquí te presentamos algunas aplicaciones clave:

| Número de Serie | Industria | Aplicación Clave | Por qué Funciona | Caso de Ejemplo |

|---|---|---|---|---|

| 1. Automotriz 🚗 | Marcado de Números de Identificación del Vehículo (VIN), números de piezas y logotipos. | Las piezas automotrices necesitan ser marcadas rápida y precisamente para cumplir con los requisitos regulatorios. La máquina de marcado láser voladora permite un marcado continuo en piezas móviles sin interrumpir el proceso de fabricación. | Un fabricante de automóviles usó el sistema para marcar los números VIN en varias piezas durante el ensamblaje. La tecnología láser voladora aseguró que las marcas fueran claras, precisas y duraderas, incluso en entornos de producción de alta velocidad. | |

| 2. Electrónica y Semiconductores 💻 | Marcado de números de serie, códigos QR y logotipos en placas de circuito, chips y otros componentes delicados. | La precisión del láser volador asegura que incluso las piezas más pequeñas puedan ser marcadas sin causar daño. Es ideal para marcar materiales como PCB (Placas de Circuito Impreso), que son sensibles a la presión mecánica. | Una empresa de semiconductores utilizó la máquina de marcado láser voladora para grabar códigos de lote en microchips. El proceso láser sin contacto garantizó que los chips no se dañaran mientras se mantenían marcas claras y legibles que cumplían con los estándares de control de calidad. | |

| 3. Dispositivos Médicos 🏥 | Marcado de números de serie, códigos de barras y símbolos regulatorios en instrumentos quirúrgicos, implantes y otros equipos médicos. | En el sector médico, la trazabilidad y la esterilización son esenciales. La máquina de marcado láser voladora proporciona marcas duraderas, limpias y a prueba de manipulaciones, necesarias para cumplir con las regulaciones. | Un fabricante de instrumentos quirúrgicos adoptó el sistema de marcado láser voladora para grabar números de serie en herramientas de acero inoxidable. Esto aseguró que cada herramienta pudiera ser rastreada a lo largo de su ciclo de vida sin comprometer su integridad. | |

| 4. Industria de Empaque y Alimentaria 🍽️ | Marcado de fechas de caducidad, números de lote y otra información en materiales de empaque, botellas y envases. | El sistema de marcado láser voladora permite el marcado continuo de alta velocidad en materiales de empaque, asegurando que los productos estén etiquetados correctamente y listos para su venta. Funciona en una variedad de materiales, incluyendo vidrio, plástico y cartón. | Una empresa de empaque de alimentos usó la máquina de marcado láser voladora para imprimir fechas de caducidad en envases a alta velocidad. La precisión y velocidad del sistema aseguraron que no hubiera interrupciones en la línea de producción de alto volumen. | |

| 5. Joyería y Artículos de Lujo 💍 | Grabado de logotipos, números de serie y diseños intrincados en anillos, relojes y accesorios. | El marcado láser ofrece la precisión necesaria para grabar detalles finos en artículos delicados como la joyería. Este proceso sin contacto asegura que las piezas se mantengan intactas mientras se conserva un alto nivel de detalle. | Una marca de joyería de lujo utilizó la máquina de marcado láser voladora para grabar códigos únicos y logotipos en sus piezas. El resultado fue marcas permanentes, de alta calidad y estéticamente atractivas, ayudando a la marca a luchar contra la falsificación. | |

| 6. Industria Aeroespacial ✈️ | Marcado de números de serie, números de pieza y datos críticos de seguridad en piezas metálicas y compuestas. | Los componentes aeroespaciales a menudo requieren marcas precisas y duraderas para identificación y cumplimiento de normativas de seguridad. La máquina de marcado láser voladora asegura que las marcas puedan soportar condiciones extremas como calor, humedad y vibraciones. | Un proveedor de componentes aeroespaciales usó la máquina de marcado láser voladora para grabar códigos de lote y números de pieza en componentes de titanio. El láser garantizó que cada pieza pudiera ser rastreada durante rigurosas inspecciones de seguridad y regulaciones. | |

| 7. Electrónica de Consumo 📱 | Marcado de logotipos, números de serie e información de productos en dispositivos electrónicos y accesorios. | La máquina de marcado láser voladora puede operar a altas velocidades, lo que la hace ideal para marcar superficies de plástico o metal en productos como smartphones, laptops y audífonos. | Un fabricante de electrónica de consumo utilizó el sistema de marcado láser voladora para grabar números de serie en smartphones. Esto permitió un fácil seguimiento de cada dispositivo durante la fabricación y ayudó a prevenir que productos falsificados ingresaran al mercado. | |

| 8. Industria de Herramientas y Equipos 🛠️ | Marcado de logotipos, números de modelo e información de lote en herramientas, equipos y productos de ferretería. | Las herramientas y productos de ferretería necesitan marcas claras y duraderas para su identificación y para proporcionar datos esenciales a los usuarios. La máquina de marcado láser voladora ofrece estas marcas sin afectar el acabado superficial ni la funcionalidad. | Un fabricante de herramientas eléctricas utilizó la máquina de marcado láser voladora para grabar números de modelo e instrucciones de seguridad en componentes metálicos. El resultado fue marcas claras y permanentes que permanecieron intactas incluso después de un uso prolongado. |

Resumen: Las máquinas de marcado láser voladoras son increíblemente versátiles y pueden aplicarse en una amplia variedad de industrias. Ya sea que estés en el sector automotriz, electrónica, dispositivos médicos o artículos de lujo, esta tecnología te ayuda a lograr marcados de alta velocidad y alta precisión que mejoran la trazabilidad, el cumplimiento y la identidad de la marca. Es la solución ideal para marcados continuos, sin contacto y ecológicos. 🌿

Máquina de Marcado Láser Voladora: La Solución Definitiva para Marcado Rápido y Preciso 🚀

Si estás buscando una máquina de marcado láser de alta velocidad y precisión, la Máquina de Marcado Láser Voladora es justo lo que necesitas. Ya sea que trabajes en fabricación, electrónica, automotriz o incluso joyería, esta máquina está diseñada para manejar una variedad de materiales y ofrecer resultados consistentes y de alta calidad.

¿Qué hace que esta máquina se destaque? 🤔

Vamos a desglosar los parámetros clave y por qué son importantes para ti:

| Parámetro | Descripción | ¿Por qué es importante? |

|---|---|---|

| Potencia Láser | 20W, 30W, 50W | Determina la velocidad y profundidad de marcado. Mayor potencia permite un procesamiento y marcado más rápido de materiales más duros. |

| Área de Marcado | 110mm x 110mm, 150mm x 150mm | Un área de marcado más grande permite marcar múltiples artículos a la vez o piezas más grandes, mejorando la flexibilidad de producción. |

| Velocidad de Marcado | 7000 mm/s | Las velocidades de marcado más rápidas aumentan la productividad, permitiendo producir más unidades por hora. |

| Tipo de Láser | Láser de fibra | Ofrece alta precisión y puede manejar varios materiales (metales, plásticos, cerámicas) con mantenimiento mínimo. |

| Resolución | 0.001mm | Ofrece detalles ultra finos, esenciales para marcas nítidas y claras, como números de serie o diseños complejos. |

| Sistema de Refrigeración | Refrigeración por aire | Previene el sobrecalentamiento durante el uso prolongado, garantizando un rendimiento constante sin necesidad de sistemas de refrigeración adicionales. |

| Calidad del Haz | <1.5M² | Garantiza precisión y claridad, produciendo marcas detalladas y de alta calidad. |

| Dimensiones | 800mm x 600mm x 1150mm | El tamaño compacto facilita la integración en configuraciones existentes mientras se mantiene la eficiencia en el uso del espacio. |

| Peso | Aproximadamente 70kg | Una máquina más pesada ofrece estabilidad durante la operación, reduciendo las vibraciones para obtener resultados consistentes. |

| Voltaje | 220V ±10% | El voltaje estándar asegura una integración sin problemas con la mayoría de las instalaciones eléctricas existentes. |

Esta Máquina de Marcado Láser Voladora no solo ofrece precisión y velocidad, sino también eficiencia. 🌟

Preguntas Frecuentes (FAQ)

1️⃣ ¿Qué es una Máquina de Marcado Láser Voladora en Línea?

Una Máquina de Marcado Láser Voladora en Línea es un sistema especializado diseñado para realizar marcado de alta velocidad y continuo en productos que se desplazan a lo largo de una línea de producción. A diferencia de las máquinas láser tradicionales, este sistema utiliza ópticas voladoras que marcan los productos mientras se mueven, lo que lo convierte en una solución ideal para procesos de manufactura de alto volumen en industrias como empaques, automotriz, electrónica y alimentos y bebidas.

2️⃣ ¿Cómo funciona la Máquina de Marcado Láser Voladora en Línea?

Esta máquina utiliza un rayo láser dirigido por ópticas voladoras que se mueven en sincronía con la línea de producción. A medida que los productos pasan por el área de marcado, el láser los marca en tiempo real. La sincronización con la línea de producción garantiza que cada producto sea marcado de manera precisa con códigos de barras, QR, números de serie o logotipos sin ralentizar la velocidad de producción.

3️⃣ ¿Qué industrias se benefician del uso de una Máquina de Marcado Láser Voladora en Línea?

La Máquina de Marcado Láser Voladora en Línea es perfecta para industrias donde los productos deben ser marcados rápida y consistentemente mientras se desplazan a lo largo de una línea de producción, tales como:

-

Empaque (marcando logotipos, códigos de lote o fechas de vencimiento)

-

Automotriz (marcando partes o números de serie)

-

Electrónica (grabado de códigos de barras, números de modelo o logotipos)

-

Alimentos y bebidas (marcando empaques con fechas de producción o vencimiento)

-

Farmacéutica (marcando botellas de medicamentos con códigos de barras e identificación)

4️⃣ ¿Qué materiales puede marcar la Máquina de Marcado Láser Voladora en Línea?

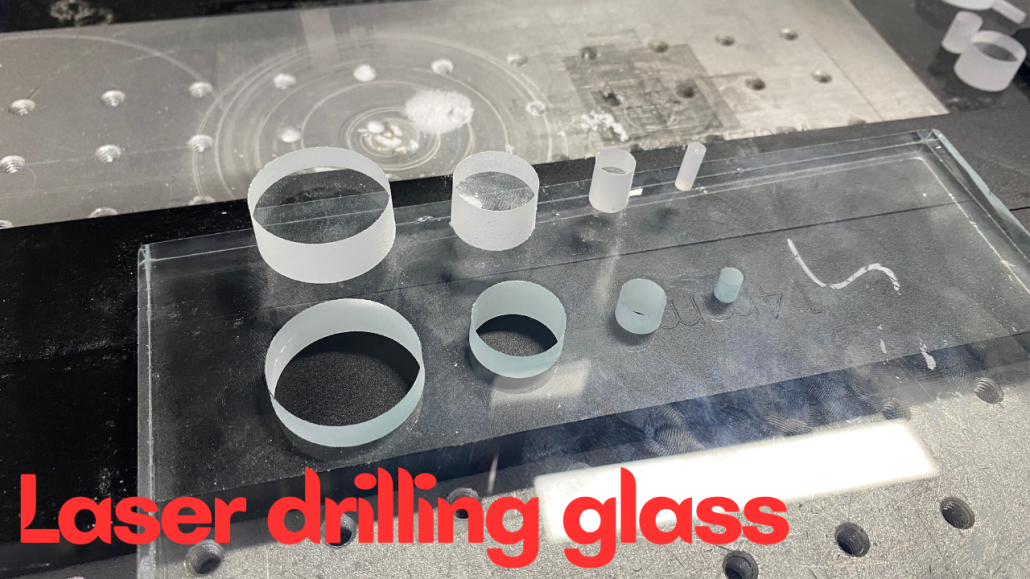

Esta máquina puede marcar una gran variedad de materiales, incluyendo:

-

Metales (acero, aluminio, etc.)

-

Plásticos

-

Cartón y papel

-

Vidrio

-

Madera

-

Textiles

-

Caucho

Es ideal para una amplia gama de procesos de manufactura donde se requiere un marcado consistente y de alta velocidad.

5️⃣ ¿Qué diferencia a la Máquina de Marcado Láser Voladora en Línea de los sistemas de marcado láser tradicionales?

La principal diferencia radica en que la Máquina de Marcado Láser Voladora en Línea está diseñada para operar sobre productos que están en movimiento a través de una línea de producción, mientras que los sistemas tradicionales requieren que los productos permanezcan estacionarios durante el proceso de marcado. Esta máquina es perfecta para entornos de alto rendimiento, donde la velocidad y la eficiencia de producción son cruciales. También se integra fácilmente con sistemas automatizados para una operación fluida.

6️⃣ ¿Cuáles son los beneficios de usar una Máquina de Marcado Láser Voladora en Línea?

-

Marcado de alta velocidad en productos en movimiento, manteniéndose al ritmo de las líneas de producción rápidas.

-

Marcado sin contacto, asegurando que el producto no sufra daños durante el proceso.

-

Alta precisión y consistencia, incluso en formas y materiales complejos.

-

Mínimo mantenimiento y bajos costos operativos, reduciendo tiempos de inactividad y mejorando el retorno de inversión (ROI).

-

Marcado personalizable, incluyendo códigos de barras, códigos QR, números de serie y logotipos.

7️⃣ ¿Es fácil integrar la Máquina de Marcado Láser Voladora en Línea a una línea de producción existente?

¡Sí! Esta máquina está diseñada para integrarse fácilmente a líneas de producción automatizadas existentes. Puede sincronizarse con sistemas de transportadores y control de movimiento para asegurar una coordinación precisa. El sistema generalmente viene con software compatible con controladores PLC, permitiendo una operación fluida sin interrumpir los flujos de trabajo existentes.

8️⃣ ¿Puede la Máquina de Marcado Láser Voladora en Línea manejar producción de alto volumen?

¡Absolutamente! La Máquina de Marcado Láser Voladora en Línea está construida para marcar de manera continua y de alta velocidad, lo que la convierte en una opción ideal para entornos de producción de alto volumen. Es capaz de marcar productos a una velocidad de cientos o miles por hora, asegurando que los procesos de manufactura a gran escala sigan siendo eficientes sin sacrificar la calidad.

9️⃣ ¿Qué tipo de mantenimiento requiere la Máquina de Marcado Láser Voladora en Línea?

Aunque la máquina requiere un mantenimiento mínimo, es importante:

-

Limpiar lentes y espejos regularmente para garantizar un rendimiento óptimo del láser.

-

Verificar la alineación del sistema para mantener la precisión del marcado.

-

Monitorear el sistema de enfriamiento para evitar el sobrecalentamiento, especialmente en aplicaciones de alta velocidad.

-

Asegurarse de que el transportador u otras partes móviles estén funcionando sin problemas.

🔟 ¿Cuál es la vida útil de una Máquina de Marcado Láser Voladora en Línea?

La Máquina de Marcado Láser Voladora en Línea está diseñada para tener una larga vida útil cuando se mantiene adecuadamente. El origen de láser de fibra generalmente dura entre 20,000 a 30,000 horas de operación continua, dependiendo del modelo y las condiciones de uso. Esto la convierte en una solución rentable para entornos de manufactura de alto volumen a lo largo del tiempo.

1️⃣1️⃣ ¿Es difícil programar la Máquina de Marcado Láser Voladora en Línea?

¡Para nada! La máquina generalmente viene con un software fácil de usar que permite una programación sencilla para diseños y textos personalizados. Puedes importar archivos CAD, logotipos u otros archivos de imagen directamente al sistema. El software ofrece herramientas simples para ajustar el tamaño, la orientación y la ubicación del texto, facilitando su adaptación a tus necesidades de producción.

1️⃣2️⃣ ¿Qué tipos de marcas puede crear la Máquina de Marcado Láser Voladora en Línea?

La Máquina de Marcado Láser Voladora en Línea puede producir una variedad de marcas, incluyendo:

-

Texto (números de serie, fechas de producción)

-

Logos

-

Códigos de barras y Códigos QR

-

Gráficos y patrones

-

Números de lote e información de productos

Estas marcas son permanentes, altamente legibles y resistentes al desgaste y factores ambientales, lo que las hace ideales para productos que requieren trazabilidad e identificación.

1️⃣3️⃣ ¿Puede la Máquina de Marcado Láser Voladora en Línea ser utilizada para grabado y corte?

Esta máquina está diseñada principalmente para marcado y grabado; sin embargo, ciertos modelos con mayor potencia también pueden realizar un corte ligero de materiales más suaves, como plásticos y metales delgados. No se utiliza típicamente para corte profundo, pero puede manejar eficazmente el grabado y el grabado superficial.

1️⃣4️⃣ ¿Qué opciones de potencia están disponibles para la Máquina de Marcado Láser Voladora en Línea?

La Máquina de Marcado Láser Voladora en Línea está disponible en varias opciones de potencia, que van desde 20W hasta 100W, dependiendo de la aplicación y el material que se esté procesando. Los modelos de mayor potencia son adecuados para marcar metales y materiales más duros, mientras que los modelos de menor potencia son ideales para plásticos y etiquetas.

Videos de la Máquina de Marcado Láser Volante

Solicite una cotización para una mini máquina de marcado láser de fibra

SISMAR LASER ofrece soluciones con máquinas de láser de fibra y otras tecnologías para diversas aplicaciones industriales. Nuestras soluciones pueden servir como una excelente actualización para su sistema de marcado láser actual o como una opción ideal para su primera máquina láser.

Solicite un presupuesto para una máquina de marcado láser de fibra de alta calidad que supere sus expectativas. También puede programar una demostración para ver cómo funciona el marcado láser de fibra.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.