3D Subsurface Laser Engraving Machine For Crystal & Glass

3D Crystal UV Laser Marking Machine – Precision and Creativity in Every Detail ✨

The 3D Crystal UV Laser Marking Machine is the ideal solution for creating intricate, multi-dimensional engravings inside crystal, glass, and acrylic. Using advanced UV laser technology, it offers exceptional precision, delivering sharp, detailed designs that appear to float inside the material. Perfect for personalized gifts, awards, trophies, and memorial pieces, this machine creates lasting memories with stunning depth and clarity.

Key features include:

- 3D engraving for depth and realism.

- UV laser precision for high-quality, detailed results.

- Versatile compatibility with crystal, glass, and acrylic materials.

- Customizable power settings (5W, 10W, and 15W) to suit different engraving needs.

Elevate your creations with the 3D Crystal UV Laser Marking Machine, designed to bring your ideas to life with unmatched detail and emotional impact. Whether for special gifts or corporate awards, this machine ensures your designs stand out with professional-grade results.

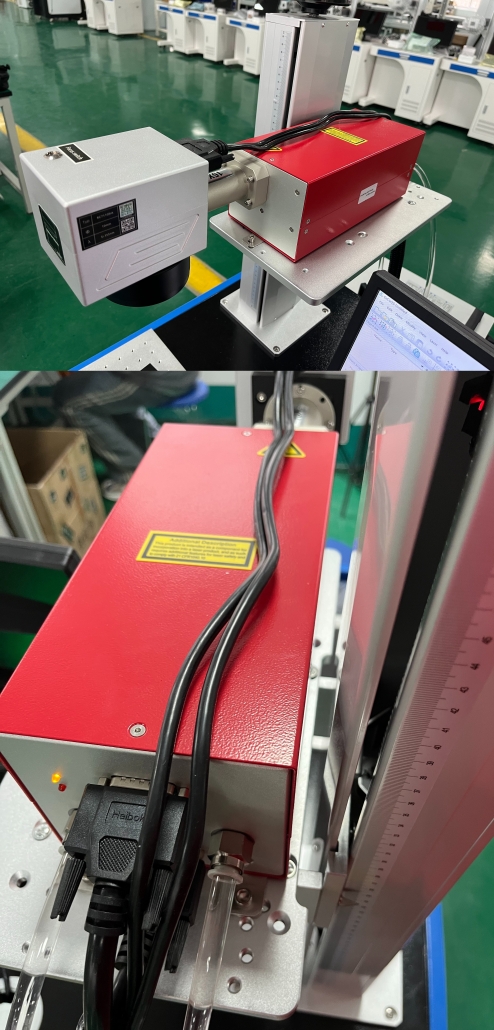

3D crystal UV Laser Marking Machine Photo

Unlock the Magic of 3D Laser Engraving with the UV Crystal Engraving Machine ✨

Imagine a world where you can capture memories, emotions, and stories inside crystal. With our 3D UV Crystal Laser Engraving Machine, that world is now within your reach.

🌟 What Makes This Machine Special?

- Precision & Detail: Powered by ultraviolet (UV) laser technology, every engraving is a masterpiece of sharp detail. The short wavelength creates stunningly crisp textures, making your designs appear to float inside the crystal.

- 3D Magic: Go beyond flat engravings. With 3D capabilities, create multi-dimensional masterpieces that provide depth and realism. Whether it’s a portrait, a logo, or a custom design, the visual impact will leave you speechless.

- Versatile Materials: Perfect for crystal, glass, and acrylic, this machine offers endless possibilities for personalized gifts, awards, trophies, and decorative art.

🚀 Why Choose Our 3D UV Laser Engraving Machine?

- Emotional Impact: Nothing compares to a personalized gift engraved inside crystal. Its emotional value makes it perfect for any occasion—weddings, anniversaries, corporate awards, or personal keepsakes.

- High-Quality Results: Expect exceptional clarity, depth, and precision. With minimal heat distortion, your designs will be flawless, ensuring that your creations are as beautiful as the memories they hold.

💡 Power Options for Every Need

Available in 5W, 10W, and 15W power settings, this machine is designed for different engraving needs:

- 5W: Ideal for delicate, fine engravings on glass and softer materials.

- 10W: A versatile option that works well with both crystal and glass.

- 15W: Perfect for deeper, more detailed engravings in crystal, providing enhanced depth and contrast.

🏆 Perfect For:

- Personalized Gifts 🎁

- Corporate Awards 🏅

- Memorial Pieces 💖

- Custom Art & Décor 🖼️

Create Unforgettable Moments

This is more than just a machine; it’s a tool that allows you to create lasting impressions. Bring your vision to life, share your story, and leave people in awe. With the 3D UV Crystal Laser Engraving Machine, you’re not just engraving—you’re creating memories that will last a lifetime.

Don’t just give a gift—give an experience. Transform your vision into a timeless masterpiece.

Unlock the Power of 3D Laser Crystal Engraving ✨

The 3D Laser Crystal Engraving Machine allows you to etch stunning 2D or 3D photos or designs inside cubes, glass, crystals, acrylic, and other hard transparent plastics. Transform ordinary materials into extraordinary works of art with unmatched precision and detail!

Industries That Can Benefit 🌟

This powerful tool isn’t just for hobbyists—it’s perfect for businesses looking to add personalized touches or eye-catching designs. Applicable industries include:

- Hotels – Unique, personalized décor and gifts

- Garment Shops – Custom logos and display pieces

- Building Material Shops – Engraved samples and designs

- Manufacturing Plants – Custom product branding and prototyping

- Machinery Repair Shops – Detailed part engravings

- Food & Beverage Factories – Custom branding on glassware and more

- Farms – Custom farm equipment or signs

- Restaurants – Engraved glassware, gifts, and décor

- Home Use – Personalized keepsakes and décor

- Retail – Custom products for customers

- Food Shops – Custom packaging and gifts

- Printing Shops – Creative engravings for promotional items

- Construction Works – Detailed engravings on building materials

- Energy & Mining – Industrial engravings for parts and equipment

- Advertising Companies – Unique promotional items and branding solutions

With our 3D Laser Crystal Engraving Machine, you’re not just engraving materials—you’re creating emotional connections and lasting impressions. 🌟

Features of 3D Subsurface Laser Crystal Engraver Machine

- The 3D laser subsurface engraving machine can engrave on both 2D and 3D (depends on your design).

- The control system is easy to operate, integrated automatic center function, operator is easy to put the crystal.

- Good beam quality, high stability, exquisite etching point effect.

- Air-cooling semiconductor laser type, high end pumped solid state laser technology is adopted.

- The 3D subsurface laser engraver supports multiple data formats of DXF, CAD, BMP, JPG with good compatibility.

- The 3D laser internal engraver is also nice for large format etching up to 300*400*130mm.

- The operation is simple: software friendly interface, easy to learn, automatic center function, convenient operation, and personnel placement crystal.

- Strong adaptability: It is equipped with shockproof system, effectively prevent to damage the core components.

- High frequency: Using high-speed galvanometer scanning method, speed up to 300000 dots/min, save the time.

- High stability engraving effect delicate: Using advanced semiconductor side pumped solid state laser technology.

- The 3D laser internal engraving machine adopts sealed integration design, good beam quality, high stability, fine engraving effect, low maintenance.

- Environmental protection, low noise (no compressor pumps and high power fan), no pollution.

FAQ for a 3D Crystal UV Laser Marking Machine:

1. What is a 3D Crystal UV Laser Marking Machine?

A 3D Crystal UV Laser Marking Machine uses ultraviolet laser technology to precisely engrave on the surface of crystal materials. It is capable of 3D marking inside the crystal, ideal for custom gifts, trophies, and souvenirs.

2. What kind of content can be marked?

The machine can mark text, patterns, QR codes, photos, and more. It supports various image and text formats, including complex 2D or 3D designs.

3. Is the machine difficult to operate?

The operation is relatively simple with an intuitive interface and dedicated software. Users just need to import design files and adjust settings to perform the marking.

4. How is the clarity of 3D marking ensured?

The machine uses high-precision UV laser technology, which allows for precise engraving in small spaces, ensuring clear and sharp details, especially for 3D marking.

5. Can it mark different sizes of crystals?

Yes, the machine supports various sizes of crystals. The working table is adjustable to accommodate different crystal dimensions.

6. What should be considered during the marking process?

- Ensure the crystal surface is clean and free from dust or oil.

- Adjust the laser power and focus for the best effect.

- Avoid strong vibrations or temperature fluctuations that could affect the marking quality.

7. Is maintenance complex?

Maintenance is relatively simple. Regular cleaning of optical lenses and checking the laser head are the main tasks. The machine features a self-diagnosis system to detect and address minor issues.

8. What is the production efficiency like?

The 3D Crystal UV Laser Marking Machine is efficient, able to mark quickly and is suitable for mass production or custom orders.

9. Can the machine be customized based on specific needs?

Yes, we offer customization options for the machine, including adjustments to laser power, work area size, and even custom software support for specific projects.

10. How safe is the laser marking process?

The machine is equipped with advanced safety features, including a laser protective cover and an emergency stop button, ensuring the operator’s safety during use.

Videos of 3D Subsurface Laser Engraving Machine For Crystal & Glass

Request a Quote for a 3D Crystal Laser Inner Engraving Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

More 3D Crystal Laser inner engraving machine

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-88804407

Fax: +86-531-88804407

Email: sales@sismarlaser.com

LATEST PRODUCTS

- EZCAD common errorMarch 18, 2025 - 2:09 am

- Small Business Guide: Navigating the Evolving 3D Crystal Engraving Market in 2025March 12, 2025 - 5:31 am

- “Continuous vs. Pulsed Laser Cleaning: Single Mode vs. Multi Mode LasersFebruary 21, 2025 - 5:54 am

- “Laser precision, zero damage—cleaning rust and paint without harming your product.”February 21, 2025 - 3:08 am

- Why Choose glass laser drilling machineJanuary 31, 2025 - 4:59 am