Large Format Mirror Laser Engraving Machine

Large format Mirror Laser Engraving Machine

Sandblasting glass laser Machine Advantages:

This machine integrates coating removal, sandblasting, and drilling functions into one, eliminating the need for separate processes. It streamlines the transformation of mirrors into sandblasted effects without the necessity of removing films or applying frosting coatings.

The machine ensures precise processing of patterns such as large rectangles, squares, circles, etc., maintaining straight lines and preventing any dislocation from occurring.

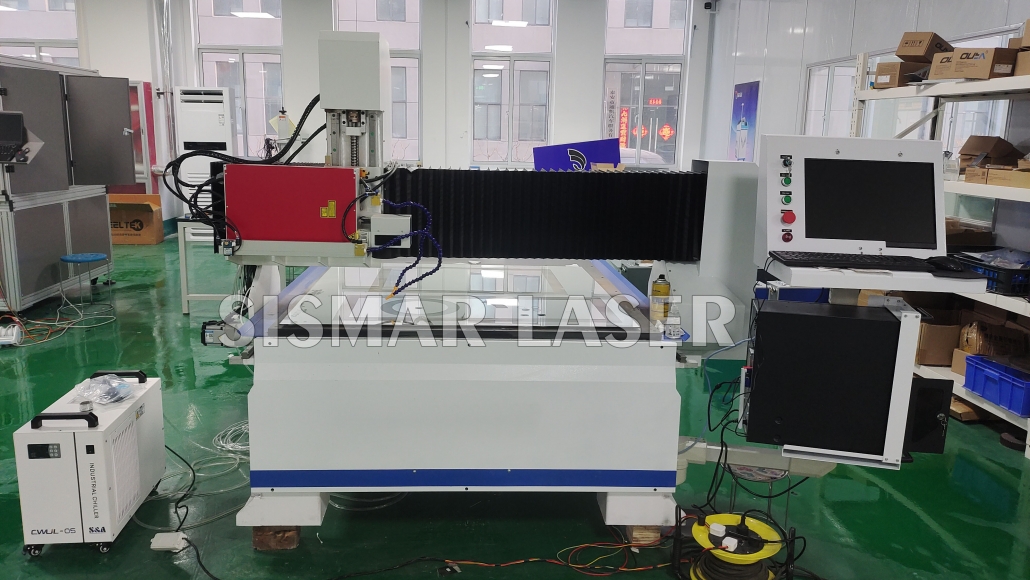

Machine Photos of Sand Blasting Glass Laser Machine

Smart mirrors embed displays, sensors and operating systems in traditional mirrors. You only need to click the button on the mirror to activate the smart mirror and perform corresponding operations, adding mirror display and human-mirror interaction functions to the mirror. , laser marking technology plays a vital role here.

Intelligent mirror laser sanding machine is a new type of equipment used in the production of intelligent mirror manufacturing.The equipment solves the intelligent mirror production process of film, engraving and painting, tearing the film of the cumbersome process, as well as easy to scratch the disadvantages of defective products.

the use of laser etching in the form of a process to make a translucent part of the graphic and the switch button part of the beautiful high-grade effect, and the production efficiency has been greatly improved, greatly reducing the cost of production of the enterprise! The production efficiency is greatly improved, greatly reducing the production cost of the enterprise, and increasing the daily production capacity of the factory by 2-3 times.

Smart mirror laser sanding machine can be used for smart mirror sanding, mirror / glass perforation, mirror de-filming three kinds of processes, greatly improving the effectiveness of the production enterprise, reduce the cost of equipment purchase.

The sanding area is created in a single process through laser processing.

With a working width of 1.5 by 3 meters, it can produce large-sized smart mirrors.Its size also can custom made according to your work.

Maintenance-free, it saves production costs and increases efficiency.

Capable of processing silver mirrors, aluminum mirrors, environmentally friendly mirrors, and other types of lamp mirrors.

The processed light-transmitting parts are neat and beautiful, without defects.

There are no consumables required for production, eliminating the need for perishable consumables.

The laser head has a lifespan of 100,000 hours.

NAME | Mirror Glass Laser Engraving and Drilling Machine |

Laser power | 100W/200W |

Laser Type | Anti-high backfoot power metal fiber laser generator |

Maximum processing material | 1.5m*3m (customizable) |

Processable light mirror materials | Silver mirror, aluminum mirror, environmentally friendly copper-free mirror, resin mirror, etc. |

Laser processing accuracy | 1 wire (0.01mm) |

Equipment power | 4500W |

Processing movement speed | 0-40m/min |

Processing thickness | 1-50mm |

Cooling method | Constant temperature water cooling |

Positioning fixture | Aluminum alloy four-station positioning fixture |

Weight(Kg) | 1500 (kg) |

The application of laser marking technology on smart mirrors specifically includes the following aspects:

Logo and pattern engraving: Laser marking machines can be used to engrave logos, patterns, text and other information on the surface of smart mirrors. These logos can include brand logos, indicative patterns, warning messages, etc., to provide users with more information and functions.

Touch button marking: Through laser marking technology, the location and function of the touch buttons can be marked on the surface of the smart mirror, so that users can easily find and operate these buttons to activate various functions of the smart mirror.

Sensor calibration: The sensor inside the smart mirror can be calibrated through laser marking technology to ensure that it accurately senses the user’s operation and environmental information. This can improve the response speed and accuracy of the smart mirror.

Beautification and decoration: Laser marking technology can be used to create exquisite textures, patterns or decorative effects on the surface of smart mirrors to enhance the look and feel of the mirror, making it more attractive and personalized.

Information display: The laser marking machine can engrave logos or instruction information on the display screen of the smart mirror to help users understand the functions and operation methods of the smart mirror more intuitively.

Laser Marking Sandblasted Glass Laser Etching Machine

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-88804407

Fax: +86-531-88804407

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Comparision of Laser glass drilling machine Green Laser VS M8 fiber laserApril 28, 2024 - 3:25 am

- Comparison of three processes for glass cutting/drilling MachineApril 28, 2024 - 3:10 am

- 3D Subsurface Laser Engraving Machine For Crystal & GlassApril 9, 2024 - 7:09 am

- Why Glass Sandlasting with fiber laser marking machine?March 29, 2024 - 1:26 am

- The difference between single mode and multi-mode in laser cleaning machineJanuary 23, 2024 - 7:17 am