🌟 Pure Gold & Silver Jewelry Laser Cutting Machine | 3KW Pendant Laser Cutter

99.99% Silver & Gold Laser Cutting Machine

Take your jewelry production to the next level. This compact yet powerful 3KW laser cutter is designed to handle up to 3mm thick pure gold and silver, delivering perfectly smooth, burr-free edges every time. Say goodbye to wasted materials and tedious manual finishing.

Whether you’re making pendants, fine jewelry, or custom designs, this machine combines precision, speed, and efficiency in one sleek package. Easy to use, reliable, and built to help you produce professional-quality jewelry faster and more cost-effectively.

Ready to upgrade your workflow and create stunning pieces with ease? Contact us today to request a quote or demo and see the difference yourself.

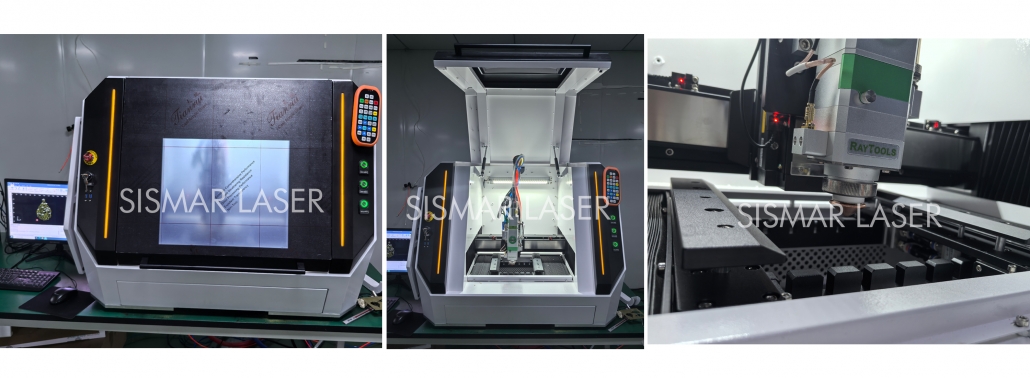

Photos of 200*300mm Fiber Laser Cutting Machine 3KW

Product Overview

The Pure Gold & Silver Jewelry Laser Cutting Machine (3KW) is specially designed for cutting gold pendants, silver pendants, and other fine jewelry pieces with unmatched precision.

With a compact 200 × 300 mm working area and powerful 3KW laser source, this jewelry laser cutting machine can cut up to 3mm thickness of pure gold and silver smoothly, without burrs or rough edges.

If you are looking for a gold laser cutting machine or a silver laser cutting machine that guarantees high precision, smooth cutting edges, and maximum material savings, this is the best solution for your jewelry workshop.

Key Features

✅ Specialized for Gold & Silver Jewelry – Perfectly optimized for cutting gold pendants, silver pendants, charms, and fine jewelry parts.

✅ High Power 3KW Laser – Ensures fast cutting speed and stability, even on pure gold and silver.

✅ 3mm Cutting Thickness – Capable of cutting up to 3mm of gold and silver sheets without deformation.

✅ 200 × 300 mm Compact Working Area – Ideal for jewelry workshops and studios with limited space.

✅ High Precision & Smooth Edges – No secondary polishing required, saving time and labor.

✅ Low Material Waste – Advanced nesting software ensures maximum utilization of expensive precious metals.

Problem & Solution (Why Choose Laser Cutting?)

| Traditional Cutting | Jewelry Laser Cutting Machine |

|---|---|

| ✂️ Rough edges – needs re-polishing | 🔥 Smooth edges – ready-to-use finish |

| 💰 High gold/silver waste | 💎 Precise cutting with minimal waste |

| 🕒 Slow & labor-intensive | ⚡ Fast, efficient, one-step process |

| ⚙️ Limited designs possible | 🎯 Complex & intricate patterns with ease |

With the Pure Gold & Silver Jewelry Laser Cutting Machine, you can save costs, increase efficiency, and deliver higher-quality jewelry products to your customers.

Technical Parameters

Model: 3KW Pure Gold & Silver Jewelry Laser Cutting Machine

Working Area: 200 × 300 mm

Laser Power: 3000W (3KW)

Cutting Thickness: Up to 3 mm (Gold / Silver)

Cutting Speed: High-speed precision cutting for pendants & fine jewelry

Cooling Method: Air cooling, compact and efficient

Software: Professional jewelry CAD/CAM software included

ROI & Cost Advantage

💰 Save Gold & Silver – Precise laser cutting reduces expensive raw material waste.

⚡ Increase Production – One operator can manage multiple jobs with high efficiency.

⏱ Faster Time-to-Market – Deliver intricate designs quickly to meet customer demand.

📈 Higher Profits – Lower cost per piece means better ROI for jewelry manufacturers.

Applications

Gold pendant cutting

Silver pendant cutting

Jewelry charm cutting

Fine jewelry pattern design

Small batch or mass production of gold & silver jewelry

Pure Gold & Silver Jewelry Laser Cutting Machine (3KW) – Advantages

Specialized for Gold & Silver Jewelry Cutting

Perfect for gold pendants, silver pendants, charms, and fine jewelry parts, ensuring professional laser cutting results every time.High-Power 3KW Laser Cutting Machine

Equipped with a 3KW high-power laser, it delivers fast, precise, and stable cutting for pure gold, silver sheets, and jewelry metals.Smooth, Burr-Free Edges

Achieve ready-to-use jewelry pieces with smooth edges, eliminating the need for secondary polishing or extra labor.Low Material Waste & Cost-Saving

Advanced laser cutting nesting software maximizes material utilization, reducing waste of expensive gold and silver, saving costs for your jewelry business.Compact Jewelry Workshop Solution

With a 200 × 300 mm working area and air cooling system, it fits small workshops, studios, and jewelry production lines while maintaining high performance.High Efficiency & ROI for Jewelry Production

Cuts intricate designs and patterns quickly, allowing one operator to manage multiple jobs efficiently, improving production speed and profit margins.Supports Custom & Complex Jewelry Designs

Perfect for custom gold and silver jewelry, pendant cutting, charms, and fine jewelry pattern design, suitable for small batch or mass production.Professional Jewelry CAD/CAM Software Included

Comes with easy-to-use jewelry design software for precision control, laser cutting planning, and seamless workflow integration.

In short: The 3KW Pure Gold & Silver Jewelry Laser Cutting Machine is a high-precision, cost-effective jewelry laser cutter designed to help jewelry workshops, studios, and manufacturers save time, labor, and material while delivering premium gold and silver jewelry.

FAQ – Pure Gold & Silver Jewelry Laser Cutting Machine (3KW)

Q1: What materials can this jewelry laser cutting machine handle?

A1: This machine is specially designed for pure gold, silver, and other precious metals, ideal for pendants, charms, and fine jewelry parts.

Q2: What is the maximum cutting thickness?

A2: It can cut up to 3mm thickness of gold or silver sheets with smooth, burr-free edges.

Q3: How precise is the laser cutting?

A3: The 3KW high-power laser ensures high precision, allowing intricate patterns and complex designs without deformation.

Q4: Does it save material?

A4: Yes. The machine comes with advanced nesting software that maximizes material utilization, reducing gold and silver waste.

Q5: What is the working area of this machine?

A5: The compact 200 × 300 mm working area fits easily in jewelry workshops, studios, or small production lines.

Q6: Is it easy to operate?

A6: Absolutely. It includes professional jewelry CAD/CAM software and a user-friendly interface, making it suitable for both beginners and professional jewelers.

Q7: Can it handle custom or small-batch production?

A7: Yes. The machine supports custom designs, small batch, or mass production, giving you full creative flexibility.

Q8: How does it compare to traditional cutting methods?

A8: Unlike traditional cutting that often produces rough edges and high material waste, this laser cutting machine delivers ready-to-use jewelry with minimal waste, saving time, labor, and costs.

Q9: What about maintenance?

A9: The machine uses a compact air-cooling system, which is low-maintenance and energy-efficient, ideal for continuous operation.

Q10: How can I get a demo or quote?

A10: You can contact us directly through our website or email to request a demo, quotation, or more technical details.

More 200*300mm fiber laser cutting machine videos

Request a Quote for a Fiber laser Cutting Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing Fiber laser cutting system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser cutting machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking cutting works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Create Flawless Jewelry & Crafts with UV Laser Seashell CuttingFebruary 10, 2026 - 4:14 am

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am