High-Speed Fiber Laser Marking System for Steel Strip Production Line

“Permanent, Precise, High-Speed Marking for Steel Strips – See the Difference Today”

Tired of slow, messy, or fading marks on your steel strips? The High-Speed Fiber Laser Marking System for Steel Strip Production Line puts an end to that. It delivers permanent, ultra-precise, high-speed marking for steel strips, coils, and sheets—no ink, no consumables, no headaches.

Get back your production speed, cut down costs, and make every mark traceable and reliable. With full PLC and MES integration, the High-Speed Fiber Laser Marking System for Steel Strip Production Line turns your steel line into a high-efficiency, worry-free powerhouse.

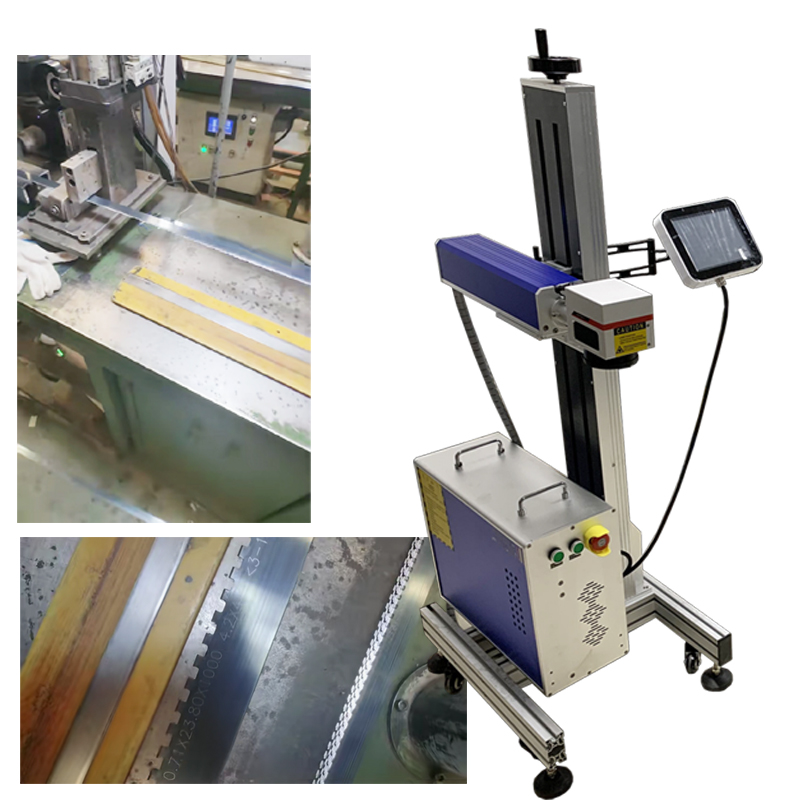

Photos of the Flying Laser Marking Machine Online

High-Speed Fiber Laser Marking System for Steel Strip Production Line

Your Production Line Deserves a Smarter Marking Solution

50W 60W High-Speed Fiber Laser Marking System — Redefining Steel Strip Marking with Millisecond Precision

1. Customer Challenges

On fast-running production lines, steel manufacturers often face three common problems:

⏱ Speed Bottleneck

Traditional marking machines cannot keep up with hundreds of meters per minute. Every slowdown causes direct production losses.❌ Unclear Identity

Ink or labels fade under friction, moisture, and corrosion. Codes become unreadable, making traceability and brand protection impossible.💰 Hidden Costs

Ink, solvents, and frequent printhead replacements drain profits over time.

2. Our Promise: A Permanent Solution

We are not just equipment suppliers—we are your long-term partner in steel strip marking.

Our 50W 60W High-Speed Fiber Laser Marking System is built to:

⚡ Mark at Full Line Speed – Up to 200m/s flying marking with High speed galvanometer + high-frequency fiber laser.

🛡 Deliver Permanent Marks – High-contrast codes engraved into the steel surface, resistant to heat, oil, and corrosion.

🔄 Enable Smart Integration – Compatible with MES/ERP systems via Modbus, Profinet, EtherCAT.

♻ Eliminate Consumables – 100,000+ hours laser lifetime, no ink, no solvents, no maintenance headaches.

3. Core Features & Benefits

High-Speed Marking – Supports continuous production lines at 200 m/min+.

Permanent Durability – Codes and graphics remain readable for life.

Ultra Precision – Min line width 0.01 mm, min character size 0.15 mm.

Flexible Marking Content – Text, logos, barcodes, QR codes, serial numbers.

Industrial Reliability – 24/7 operation, IP54 protection, compact air-cooled design.

Cost Efficiency – Zero consumables, low power consumption (<800 W).

4. Technical Specifications

| Category | Specification | Note |

|---|---|---|

| Laser Source | Fiber Laser (30W / 50W / 60W) | Global leading brands |

| Wavelength | 1064 nm | Suitable for metals |

| Lifetime | >100,000 hrs (MTBF) | Maintenance-free |

| Marking Performance | Max speed 12,000 mm/s (XX m/s) | Matches high-speed lines |

| Min line width ≤ 0.01 mm | Ultra-fine marking | |

| Min character size 0.15 mm | For dense codes | |

| Field size 110×110 mm (customizable) | Adaptable to strip width | |

| Control & Software | Industrial PC + professional software | User-friendly |

| Modbus TCP/IP, Profinet, EtherCAT | MES/ERP integration | |

| Auto coding, database link | Supports automation | |

| Mechanical Design | Air cooling | No water chiller needed |

| Power: AC 220V ±10%, 50/60 Hz | Easy installation | |

| Consumption < 800 W | Energy efficient | |

| Protection IP54 | Harsh factory environments | |

| Operating Conditions | Temperature 0–45°C | Stable in industrial settings |

| Humidity ≤95% (no condensation) | Reliable in humid conditions |

5. Applications

The 50W 60W High-Speed Fiber Laser Marking System is designed for a wide range of steel strip and flat metal processing industries, including:

Steel Strips & Coils – Continuous marking for traceability and branding

Galvanized Steel Sheets – Anti-rust and construction-grade steel products

Stainless Steel Plates – Corrosion-resistant applications in food, medical, and chemical industries

Automotive Steel Materials – Vehicle body panels, frames, and components

Building & Construction Steel – Pipes, beams, flooring, and decorative panels

Metal Supply Chains – Warehousing, distribution, and export identification

👉 Whether for traceability, compliance, or branding, our system ensures clear, permanent, and high-speed marking that matches your production pace.

6. Customer Success Story

Production Manager, Steel Pipe Manufacturer

“We used to rely on inkjet coders, but they couldn’t keep up with our production speed, and marks often blurred. After switching to your fiber laser system, I was impressed immediately. Our line efficiency increased by 15%, and we haven’t had downtime due to marking since. Now, we proudly show customers our permanent, high-quality codes—our reputation has grown stronger than ever.”

Comparison: High-Speed Fiber Laser Marking System for Steel Strip Production Line vs. Other Marking Methods

| Feature / Method | High-Speed Fiber Laser Marking System for Steel Strip Production Line | Inkjet Printing | Mechanical Stamping | Labeling |

|---|---|---|---|---|

| Marking Quality | Permanent, high-contrast, precise — codes remain readable for product lifetime | Medium, may blur or fade | Durable but limited to fixed designs | Low, easily damaged or peeled |

| Durability | ✔ Resistant to heat, corrosion, and friction | ✘ Fades under abrasion, chemicals, or UV | ✔ Strong, but deforms material surface | ✘ Poor, adhesive weakens over time |

| Speed | ✔ Flying marking up to 200 m/min+, perfectly synchronized with steel strip production lines | High, but affected by ink drying | ✘ Slow, limited by mechanical contact | Medium |

| Flexibility | ✔ Supports text, logos, serial numbers, barcodes, QR codes, and variable data | Limited fonts and graphics | ✘ Low, requires mold changes | Medium |

| Consumables | None — zero ink, solvents, or labels | Ink, solvents, printheads required | Dies and replacement parts | Labels and adhesives |

| Maintenance | Very low — >100,000 hrs lifetime, no consumables | High (frequent nozzle cleaning and replacements) | Medium (mechanical wear) | Medium (adhesive and jam issues) |

| Operating Cost | Very low (no ongoing consumable cost) | High (continuous ink/solvent cost) | Medium to high | Medium |

| Environmental Impact | ✔ Eco-friendly, no chemical waste | Generates chemical waste | Noise, material deformation | Generates plastic/paper waste |

| Integration | ✔ Easy integration with PLC, MES, ERP systems for automated production lines | Limited connectivity | Hard to automate | Limited |

Why Choose High-Speed Fiber Laser Marking System for Steel Strip Production Line?

Compared to inkjet, stamping, or labeling methods, the High-Speed Fiber Laser Marking System for Steel Strip Production Line offers the perfect balance of:

Permanent, non-fading identification for traceability and compliance

High-speed performance that matches modern steel strip production lines

Zero consumables and low operating costs, ensuring long-term savings

Seamless integration with automated manufacturing systems

Eco-friendly operation, reducing chemical and material waste

👉 For manufacturers seeking speed, reliability, and cost efficiency, the High-Speed Fiber Laser Marking System for Steel Strip Production Line is the most advanced and future-proof solution.

FAQ – High-Speed Fiber Laser Marking System for Steel Strip Production Line

1. What is the High-Speed Fiber Laser Marking System for Steel Strip Production Line?

It is an advanced fiber laser marking solution designed specifically for continuous steel strip production lines. It provides high-speed, permanent, and precise marking of text, serial numbers, barcodes, QR codes, and logos directly onto steel surfaces, without consumables.

2. How fast can the system mark on steel strips?

The High-Speed Fiber Laser Marking System for Steel Strip Production Line supports flying marking speeds up to 200 m/min or more, fully synchronized with modern high-speed steel production lines.

3. What types of information can be marked?

The system can mark:

Text, batch codes, and serial numbers

Barcodes and QR codes for traceability

Logos and graphics for branding

Variable data linked to MES/ERP systems

4. Is the marking permanent?

Yes. Fiber laser marking creates high-contrast, non-removable engravings on the steel surface. Marks are resistant to abrasion, heat, corrosion, and oil, ensuring long-term readability.

5. Does it require ink or other consumables?

No. Unlike inkjet printers, the High-Speed Fiber Laser Marking System for Steel Strip Production Line uses pure laser technology. It has zero consumables, saving costs and avoiding chemical waste.

6. How reliable is the system?

The fiber laser source has a lifetime of over 100,000 hours. Combined with air cooling and industrial-grade design, the system can operate 24/7 in harsh environments with minimal maintenance.

7. Can it be integrated into existing production lines?

Yes. The system supports PLC, Modbus TCP/IP, Profinet, EtherCAT, and can be seamlessly integrated with MES/ERP systems for automated marking and data traceability.

8. What are the advantages compared to inkjet or stamping?

Higher speed – up to 200 m/min

Permanent durability – resistant to wear and corrosion

Zero consumables – no ink, solvents, or molds

Lower operating cost – long-term cost savings

Eco-friendly – no chemical waste or labels

9. What industries benefit from this system?

The High-Speed Fiber Laser Marking System for Steel Strip Production Line is widely used in:

Steel coils and strips manufacturing

Automotive steel parts

Building & construction steel materials

Stainless steel and galvanized sheet production

Supply chain and export identification

10. How can I test if it works for my production line?

You can request a free demo or sample marking. Our engineers will test your steel strip materials and provide a tailored solution that matches your production speed and requirements.

Videos of Flying Laser Marking Machine

Request a Quote for a Online Flying Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am

- EZCAD common errorMarch 18, 2025 - 2:09 am