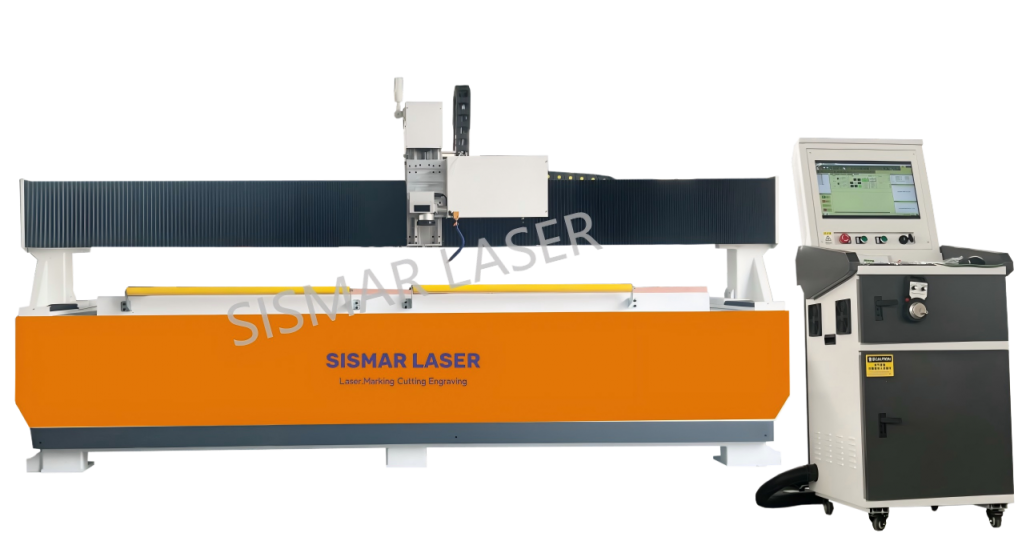

600×600 мм волоконный лазерный станок для резки металла

November 14, 2025 /0 Comments/in Language /by linda

600×600 мм волоконный лазерный станок для резки металла

Компактный. Точный. Прибыльный. Идеальный лазерный резак малого формата для ценных материалов.

Компактный, точный и мощный — этот волоконный лазерный станок предназначен для обработки ювелирных изделий, очков, электронных компонентов и медицинских микропартий. С рабочей зоной 600 × 600 мм он обеспечивает точность на уровне микрон при работе с золотом, серебром, титаном, нержавеющей сталью и другими деликатными материалами. Высокоточный линейный привод и индивидуальная система зажима обеспечивают чистоту каждого разреза при минимальных потерях материала, что делает его идеальным для небольших мастерских и специализированных производственных линий.

Разработанный с учетом эффективности и глобальных стандартов, станок имеет полностью закрытую конструкцию, сертифицированную по стандарту CE, с интегрированной системой удаления пыли. Операторы могут выбрать управление CypCut или RayTools для быстрой настройки и легкого обучения. Компактные размеры экономят ценное пространство, снижают эксплуатационные расходы и обеспечивают быструю окупаемость инвестиций. Для компаний, ищущих надежный волоконный лазерный станок малого формата, сочетающий безопасность, скорость и высокую точность, эта модель представляет собой отличное решение.

Волоконный лазерный станок с рабочей зоной 600 × 600 мм

🔥 600 × 600 мм Малый Волоконный Лазерный Станок для Резки

Компактный. Точный. Прибыльный.

Идеальный малогабаритный лазерный станок для обработки дорогих материалов.

Если вы работаете в ювелирной отрасли, производстве очков, электронике или медицинских компонентах, вы знаете, насколько важна точность. Даже одна маленькая ошибка может стоить сотни или тысячи долларов.

✅ Наш волоконный лазерный станок 600 × 600 мм создан, чтобы обеспечить микронную точность, быстрый ROI и полное спокойствие.

💡 Это не просто еще один лазерный резак.

Это инструмент для малых мастерских и высокоценных производств, где каждый миллиметр имеет значение.

⚡ Почему этот Волоконный Лазерный Станок Особенный

Большинство лазерных станков на рынке:

-

Громоздкие

-

Дорогие в эксплуатации

-

Требуют много места и специализированных операторов

Наш малый волоконный лазерный станок решает все эти проблемы:

🏠 Ультра-компактные размеры (600 × 600 мм)

Встанет даже в небольших мастерских. Идеально для бизнесов, которым нужна точность, но нет огромного производственного цеха.

🎯 Высокоточный линейный привод

Микронная точность резки = меньше отходов и идеальные результаты с дорогими металлами: золото, серебро, платина, титан.

🔧 Индивидуальные прецизионные зажимы

Надежно фиксируют деликатные детали, экономя время на перенастройку. Быстрая установка = больше продукции.

🛡 Полностью закрытая конструкция & CE сертификация

Обеспечивает безопасность операторов, контролирует пыль и отходы, соответствует европейским стандартам безопасности.

⚙ Гибкая система управления

Выбирайте между:

-

CypCut – удобный и популярный

-

RayTools – продвинутый, идеально для автоматизации

Ваши сотрудники смогут начать резку почти сразу с минимальным обучением.

🎯 Кто должен рассмотреть этот станок

Наш волоконный лазерный резак 600 × 600 мм идеально подходит для бизнесов, которым нужны:

-

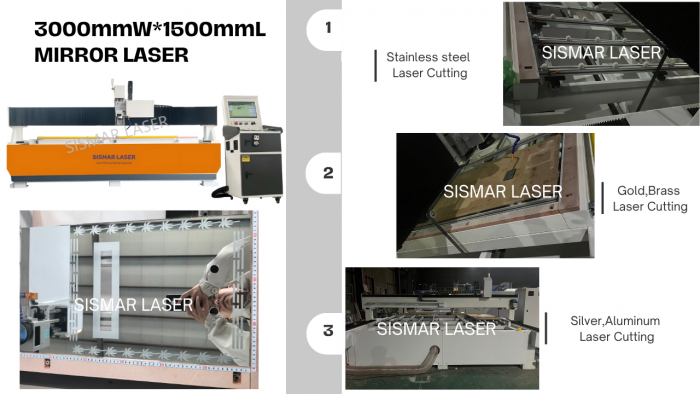

Ювелирные изделия из драгоценных металлов – резка золота, серебра и платины с микронной точностью

-

Компоненты очков – нержавеющая сталь, титан и ацетатные оправы с идеальной посадкой

-

Микро-оборудование и электроника – быстрое, качественное производство приборов, вапорайзеров и мелких кастомных деталей

-

Медицинские и электронные микро-компоненты – чистое и точное изготовление миниатюрных деталей

❗ Этот станок не для всех.

Он для тех, кто ценит точность, эффективность и прибыль, а не просто хочет «лазерный резак».

⚙ Дополнительные Конфигурации для Максимальной Гибкости

🔹 Источник Волоконного Лазера:

-

1500 W – Быстрая и точная резка тонких и отражающих материалов. Низкое энергопотребление.

-

3000 W – Обрабатывает более толстые листы или увеличенные объемы производства.

🔹 Система Управления:

-

CypCut – Простая и надежная.

-

RayTools – Продвинутая автоматизация и интеграционные функции.

💡 Эти опции позволяют подстроить станок под ваш рабочий процесс, экономить время и максимизировать прибыль.

📊 Технические Характеристики в Кратком Обзоре

| Параметр | Характеристика |

|---|---|

| Рабочая зона | 600 × 600 мм |

| Источник лазера | 1500 W / 3000 W (макс.) |

| Система движения | Высокоточный линейный привод |

| Точность позиционирования | ±0.005 мм |

| Точность повторного позиционирования | ±0.003 мм |

| Макс. скорость резки | До 40 м/мин |

| Система управления | CypCut (стандарт) / RayTools (опция) |

| Особенности безопасности | Полностью закрытая конструкция, соответствие CE |

| Габариты станка | Ш 1.8 × Г 1.5 × В 1.8 м |

| Метод охлаждения | Промышленный водяной чиллер |

| Помощные газы | O₂, N₂, сжатый воздух |

🔍 Сравнение Волоконного Лазерного Станка 600 × 600 мм с Другими Волоконными Лазерными Резаками

1️⃣ Размер и Занимаемая Площадь

-

Модель 600 × 600 мм: Ультра-компактная (1.8 × 1.5 × 1.8 м), идеально подходит для ювелирных студий, мастерских по изготовлению очков и малых электронных лабораторий.

-

Стандартные листовые резаки (1.5 × 3 м и больше): требуют значительно больше площади и инвестиций в инфраструктуру, что делает их непрактичными для мелкосерийного и точного производства.

2️⃣ Точность и Система Привода

-

Наш станок: высокоточный линейный модульный привод, обеспечивает позиционирование ±0.005 мм — идеально для микрокомпонентов и драгоценных металлов.

-

Обычные машины: часто используют зубчатые рейки с допуском ±0.02 мм, что подходит для крупных листов металла, но не для тонких ювелирных изделий или медицинских деталей.

3️⃣ Фокус на Применении

-

600 × 600 мм: специально для золота, серебра, титана, нержавеющей стали и других тонких и дорогих материалов, где важна микронная точность.

-

Большие волоконные лазеры: созданы для тяжелой промышленной резки листового металла (углеродистая сталь, толстая нержавейка), но избыточны и неэффективны для деликатных деталей.

4️⃣ Эксплуатационные Расходы и ROI

-

Малогабаритный станок: низкое энергопотребление (1500–3000 W), минимальный расход газа, быстрая настройка, окупаемость 7–12 месяцев.

-

Высокомощные установки: высокий расход энергии и обслуживания, длительный срок окупаемости при мелкосерийном производстве.

5️⃣ Безопасность и Соответствие Стандартам

-

Наш резак: полностью закрытая конструкция, сертификация CE, встроенная система удаления пыли — чистое, безопасное производство, готовое к экспорту.

-

Многие промышленные модели: часто требуют внешних защитных ограждений для соответствия европейским и американским стандартам безопасности.

✅ Вывод:

Если ваша цель — экономия пространства, микронная точность и быстрая окупаемость, волоконный лазерный станок 600 × 600 мм явно превосходит традиционные крупноформатные лазеры для малого и дорогого производства.

❓ Часто задаваемые вопросы о Волоконном Лазерном Станке 600 × 600 мм

1️⃣ Какие материалы может резать станок 600 × 600 мм?

Он обрабатывает широкий спектр металлов, включая золото, серебро, платину, нержавеющую сталь, титан, медь и алюминий, что делает его идеальным для ювелирного производства, изготовления очков, электроники и микро-компонентов.

2️⃣ Какая максимальная толщина резки?

-

С источником 1500 W можно резать тонкие листы до 3–4 мм (в зависимости от материала).

-

Опция 3000 W позволяет резать более толстые материалы, увеличивая производительность.

3️⃣ Насколько точна машина?

Высокоточный линейный модульный привод обеспечивает:

-

Позиционирование ±0.005 мм

-

Повторяемость ±0.003 мм

Каждый раз гарантируются чистые резы на уровне микрон.

4️⃣ Есть ли у станка сертификация CE?

Да. Станок имеет полностью закрытую конструкцию, соответствует стандартам CE и оснащен встроенной системой удаления пыли, что обеспечивает соответствие европейским и американским стандартам безопасности.

5️⃣ Какие системы управления доступны?

Можно выбрать между:

-

CypCut – удобная и популярная

-

RayTools – продвинутая, идеально для автоматизации и интеграции

Минимальное обучение операторов — быстрый старт производства.

6️⃣ Какие габариты станка?

Компактная рама 1.8 × 1.5 × 1.8 м экономит ценное пространство в мастерской, сохраняя промышленный уровень производительности.

7️⃣ Какой типичный срок окупаемости (ROI)?

Большинство клиентов достигают окупаемости за 7–12 месяцев, в зависимости от объема производства, благодаря низким эксплуатационным расходам и высокой эффективности резки.

8️⃣ Какое обслуживание требуется?

Регулярная проверка оптики, фильтров и промышленного водяного чиллера поддерживает станок в отличном рабочем состоянии. Сложного ежедневного обслуживания не требуется.

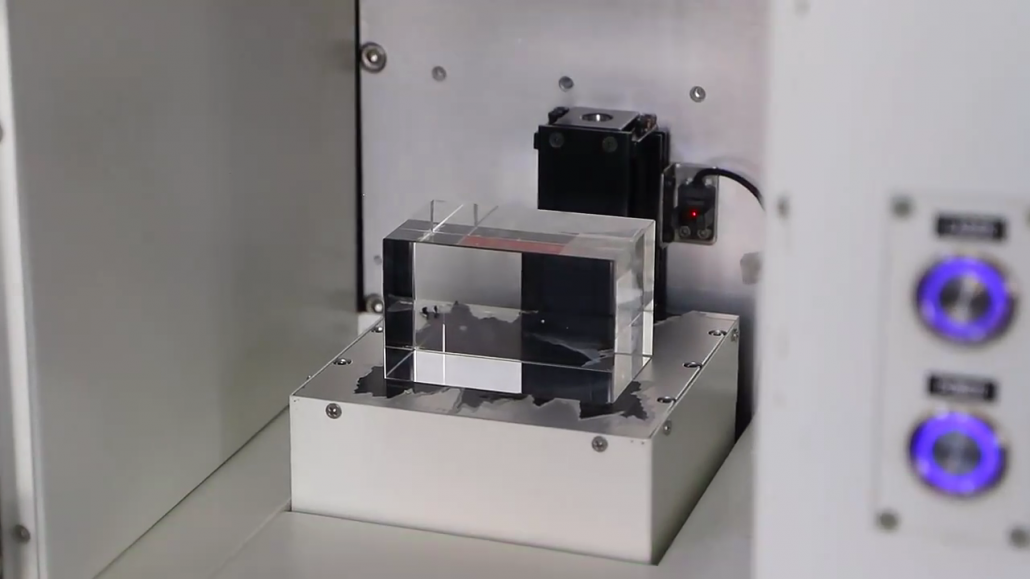

Видео по лазерной резке металла

Запросить коммерческое предложение на волоконный лазерный станок

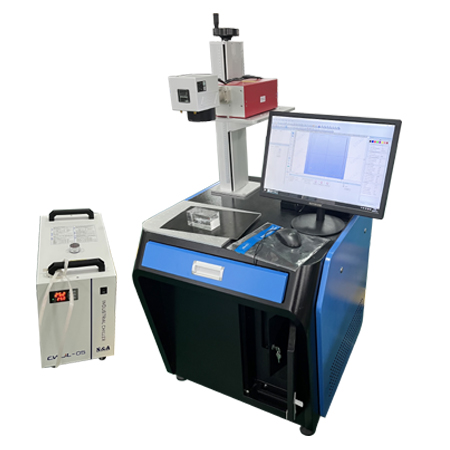

SISMAR LASER предлагает волоконные лазерные станки и другие решения для множества промышленных применений. Наши решения могут служить как модернизацией вашей существующей системы волоконной лазерной резки, так и отличным выбором для вашей первой лазерной машины.

Запросите коммерческое предложение на высококачественный волоконный лазерный станок, который превзойдет ваши ожидания. Вы также можете записаться на демонстрацию, чтобы увидеть, как работает волоконная лазерная резка и маркировка.

Добро пожаловать в SISMAR Laser! Мы будем рады ответить на любые ваши вопросы о наших волоконных лазерных станках для маркировки и резки.