Comparison 2.5D laser VS 3D laser on deep relief

For laser processing 3D relief effects, there are 2D galvanometers and 3D galvanometers on the market, so what is the difference between them?

First of all, whether 2D or 3D galvanometer is processed in relief,

Their working principle is to slice the 3D model to be processed through the software, and then process the relief layer by layer.

However, their processing processes are completely different.

2D laser galvanometer processing relief

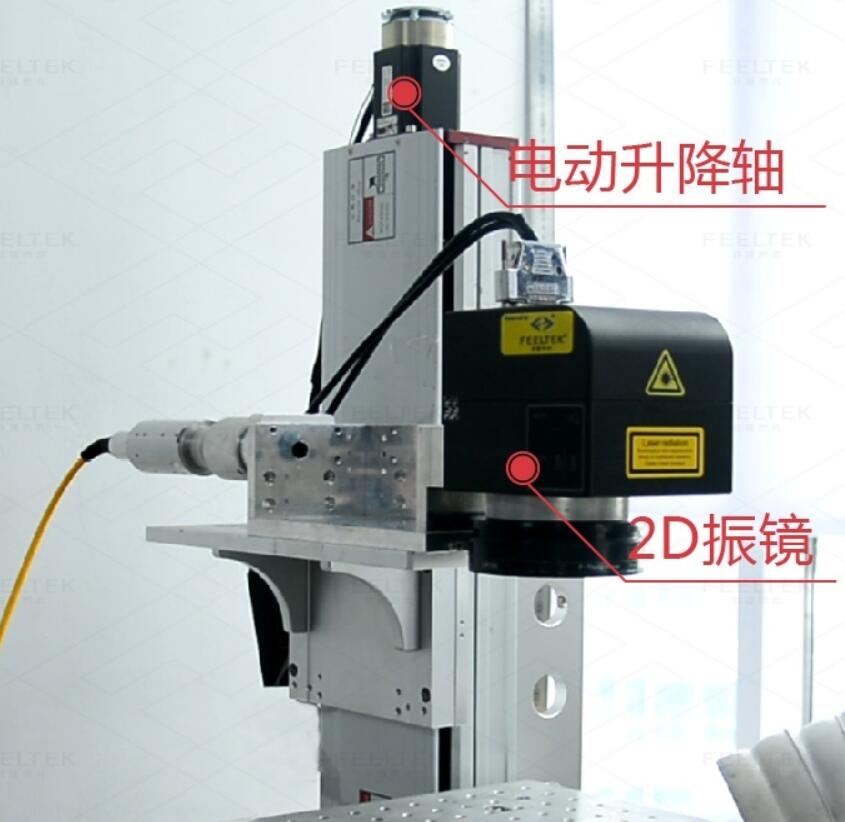

The 2D laser galvo model,we also called it 2.5D fiber laser,because laser head still with a 2D laser head,but this kind machine with motorized lifting pillar.

And the 2D galvo head can be controlled by software,software can control laser head move when machine working,so this is why it can acheieve Deep relief work.

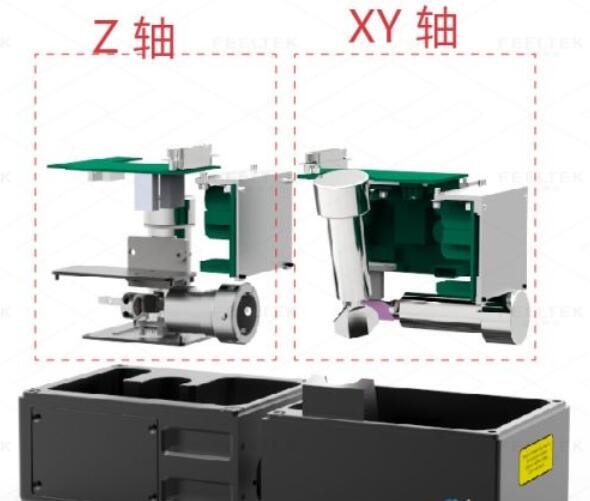

The technical difference: 3D fiber laser with 3D galvo head which have Z axis mirror,which can move back and forth;

The 2.5D fiber laser with 2D galvo head,which have not the Z axis mirror.It used the Motorized lifting pillar stands for the third mirror to move automatically.

Its working process is: in the process of processing, each layer is processed, the motorized lifting pillar moves, adjusts the height of the galvanometer, and then emits laser, so as to ensure that the laser spot is well focused on each layer, and finally achieve the relief effect.

The 2D galvanometer paired with the lift table not only greatly reduces the cost, but also the 2D galvanometer correction work is relatively simple, quick to get started, and suitable for beginner users.

And pls kindly note:2.5D laser engraving machine can finish all 2D laser work and can make 3D laser engraving on flat plate. 2.5D CANNOT make 3D engraving on curved part.

Lifting pillar of 2.5D laser machine must be motorized type. Because laser head need to re adjust the focus during engraving.

3D laser galvanometer processing relief

3D means dynamic focusing.3D laser machine with 3D galvo head,which have three mirrors,the Z axis mirror can be moved back and forth.

The 2.5D laser with 2D galvo head,which only have two mirrors.

This is the key technology of 3D laser marking machine.

Its working process is: the joint coordination of the Z-direction dynamic axis and the XY-axis is controlled by software. With the difference of the number of processing layers, the Z-direction dynamic axis moves back and forth to focus compensation to ensure the consistency of the light spot during the whole work process.

In contrast, when the 3D galvanometer is processing relief, the Z-axis and the XY-axis are fully coordinated, which can achieve nearly microsecond forward and backward movement focus compensation, without being restricted by an external lift table, and higher efficiency and accuracy. The 3D galvanometer is more inclined to industrialized products.

More info need regarding 2.D laser and 3D laser,contact sales@sismarlaser.com