Optical fiber laser metal cutting technology

Laser cutting is replacing the traditional mechanical knife with a laser beam. It has the characteristics of high accuracy, fast cutting speed, not limitation of cutting pattern, smooth cut, and low processing cost. It will gradually improve or replace the traditional metal cutting process. There is no need to directly contact the material to be processed, and it will not cause scratches on the surface of the workpiece during work; the laser cutting speed is fast, the incision is smooth and flat, and generally no subsequent processing is required.

Principle and Application of Fiber Laser engraving Cutting Machine

Fiber laser cutting uses the high-energy density laser beam of the fiber laser to focus on the surface of the workpiece, so that the area irradiated by the focused spot of the workpiece is instantly melted or vaporized, and at the same time, auxiliary air blowing blows away the slag to form a smooth slit. Fiber laser cutting has a wide range of applications, and is widely used in sheet metal processing, aviation, aerospace, electronics, electrical appliances, local automobiles, precision accessories, ships, metallurgical equipment, household appliances, craft gifts, tool processing, metal external processing, kitchenware processing, etc. Kind of manufacturing and processing industries.

Fiber laser cutting process

Fiber laser cutting processes are mainly divided into two categories:

1) Cutting by the cutting head, the laser beam is focused by the cutting head and irradiated to the surface of the workpiece, while assisting coaxial blowing, cutting through the XY axis platform movement;

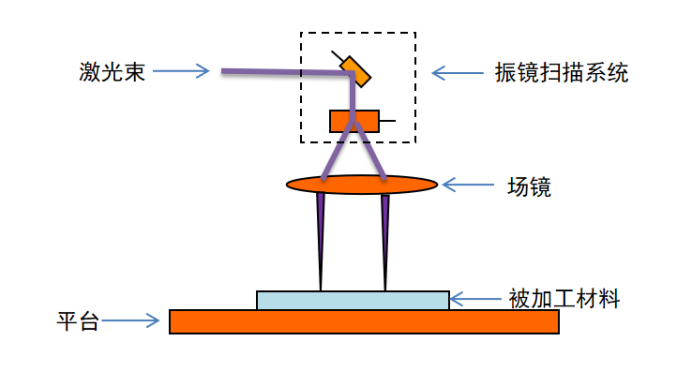

2) Cutting by galvanometer, the laser beam is rotated by the XY galvanometer lens to reflect the laser to the surface of the material, and at the same time assist blowing to cut. This article mainly introduces the cutting process of MOPA laser using galvanometer. Figure (1) is the basic principle diagram of galvanometer cutting

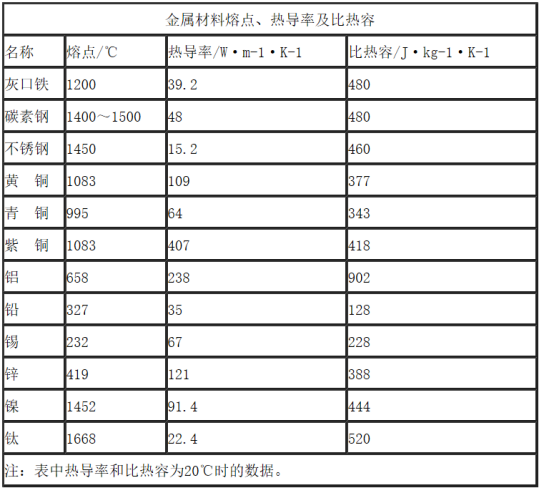

The cutting materials are stainless steel, aluminum, brass, copper, etc., and the corresponding melting point, thermal conductivity and specific heat capacity are shown in the figure

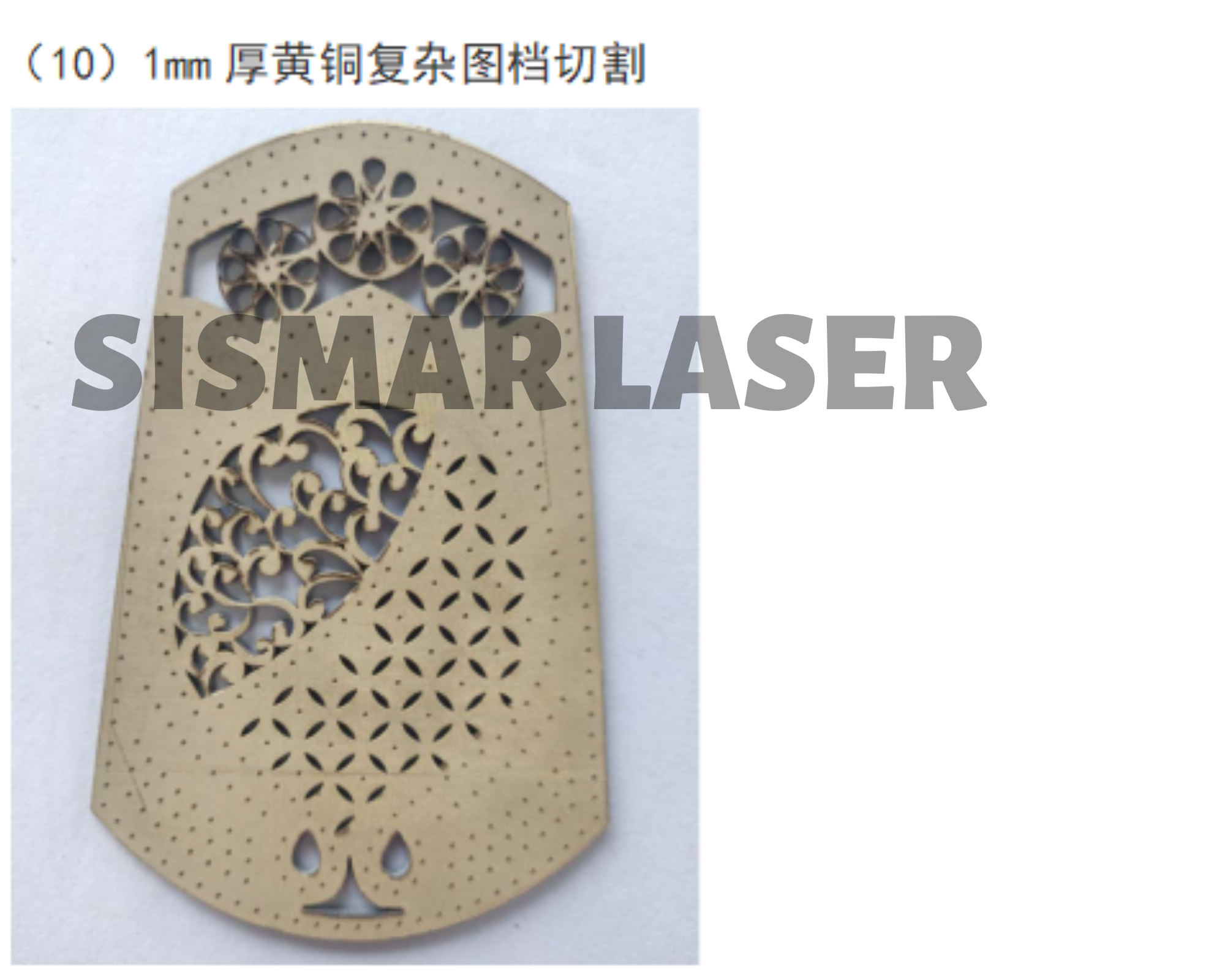

Fiber laser cutting sample display

The size of the circle and square cut in the following pictures are both 15mm