Can you clearly identify the ” laser ID card “of the surgical mask?

The epidemic caused by the new #Coronavirus/#COVID-19 raged across the world, and the demand for #surgical masks. In the current epidemic, a small mask affects all industries.

At present,in China many energy and manufacturing companies of Foxconn, BYD, SAIC-GM-Wuling, Sinopec, and GAC have joined the army of conversion masks; data show that from January 1 to February 7, 2020, there are more than 3000 The business scope of the company has newly added “masks, protective clothing, disinfectant, thermometer, medical equipment” and other businesses, and actively fights against the “epidemic”.

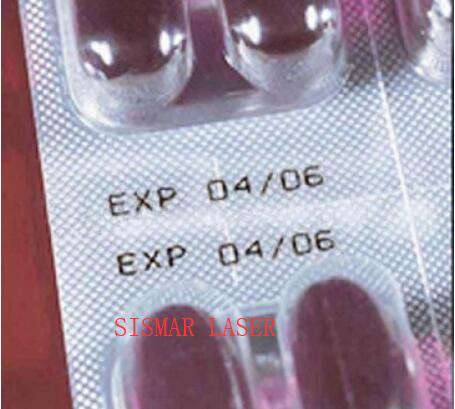

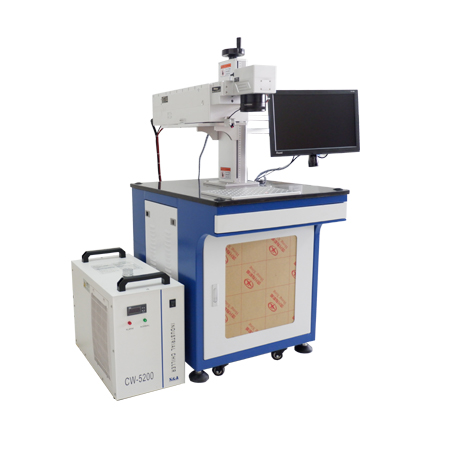

In fact, not only in the identification of masks, laser marking has always been closely related to the pharmaceutical industry, and it has been widely used in precision medical equipment, medical packaging, pills, soft capsules and other areas with special needs.