Author Archive for: linda

About linda

This author has yet to write their bio.Meanwhile lets just say that we are proud linda contributed a whooping 427 entries.

Entries by linda

🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving System

December 15, 2025 /0 Comments/in Blog /by lindaWhy Choose a Laser Marking Machine with Modular Sliding Platform for Your Factory

December 15, 2025 /0 Comments/in Blog /by lindaآلة السفع الرملي بالليزر لمرآة الفولاذ المقاوم للصدأ (1300×2500 مم)

December 4, 2025 /0 Comments/in Language /by linda

آلة السفع الرملي بالليزر لمرآة الفولاذ المقاوم للصدأ (1300×2500 مم)

اجعل ألواح الستانلس ستيل المرآوية مثالية في كل مرة.

آلة السفع الرملي بالليزر لسطح المرآة من الستانلس ستيل (1300×2500 مم)

قم بترقية عملية تشطيب الستانلس ستيل الخاصة بك باستخدام آلة السفع الرملي بالليزر لمرآة الستانلس ستيل بقياس 1300×2500 مم.

مصممة لألواح المصاعد، الألواح الجدارية الزخرفية، صفائح المطابخ، والأعمال المعدنية المعمارية، وتوفر تشطيبًا مطفيًا مثاليًا وخاليًا من الخدوش في كل مرة.

مزودة بليزر فايبر JPT M7 / Guangzhi بقوة 100 واط، وطاولة شفط من النايلون، ونظام التتبع التلقائي “Engraving-on-the-Go” الذي يضبط تلقائيًا أي انحناء أو تقوس في الألواح لضمان توحيد مثالي.

ودّع الرمال والغبار والتنظيف المرهق، واستمتع بإنتاج أسرع، وتكاليف عمالة أقل، وجودة ثابتة قابلة للتكرار—مناسب تمامًا للإنتاج الصغير والكبير في المصانع.

صور آلة السفع الرملي بالليزر للمرايا

🛑 توقف عن المعاناة مع التشطيبات المطلية غير المتساوية

إذا سبق لك العمل مع الستانلس ستيل المرآوي، فأنت تعرف الإحباط:

-

🔹 لوحة تبدو رائعة، والأخرى عليها خطوط

-

🔹 السفع الرملي التقليدي يخلق الغبار والفوضى وهدر المواد

-

🔹 اللوحات الكبيرة صعبة المعالجة والحصول على تشطيب متساوٍ

✅ تم تصميم هذه آلة السفع الرملي بالليزر بقياس 1300×2500 مم للمحترفين الذين يحتاجون إلى تشطيبات مطفية مثالية على ألواح الستانلس ستيل المرآوي، أبواب المصاعد، صفائح المطابخ، والألواح الزخرفية، في كل مرة.

لماذا هذه الآلة مهمة

الطرق التقليدية بطيئة، فوضوية، وغير متسقة. حلنا بالسفع الرملي بالليزر يغير قواعد اللعبة:

-

🟢 مساحة عمل كبيرة 1300×2500 مم → معالجة اللوحات كاملة دون الحاجة لإعادة وضعها

-

🟢 طاولة شفط بالنيليون → تثبت الصفائح، تحمي السطح، وتضمن تشطيب مطفي متساوٍ

-

🟢 ليزر 100W JPT M7 / Guangzhi → طاقة متسقة للحصول على نتائج مطفية ناعمة وعالية الجودة

-

🟢 نظام التتبع التلقائي “Engraving-on-the-Go” → يتبع الانحناءات الطفيفة أو التشوهات، ليبقي التشطيب متساويًا تمامًا

-

🟢 لا رمل، لا غبار، لا تنظيف → أكثر أمانًا، أنظف، وأرخص من السفع الرملي التقليدي

💡 فكر فيها على أنها الدقة، السرعة، والاعتمادية جميعها في آلة واحدة.

كيف تعمل

1️⃣ ضع لوحتك من الستانلس ستيل المرآوي على طاولة الشفط بالنيليون

2️⃣ يتتبع الليزر اللوحة تلقائيًا، ويضبط نفسه مع الانحناءات أو التشوهات

3️⃣ يتم إنشاء تشطيب مطفٍ ناعم ومتسق، مثل السفع الرملي التقليدي، لكن أسرع وأنظف ورقمي بالكامل

4️⃣ اللوحات جاهزة للتركيب أو التسليم – لا غبار، لا خدوش، لا تخمين

مثالية لهذه التطبيقات

-

🚪 أبواب ولوحات المصاعد

-

🖼️ الألواح الجدارية الزخرفية

-

🍳 صفائح مطابخ الستانلس ستيل

-

🏛️ الأعمال المعدنية المعمارية والداخلية

-

✨ أنماط أو شعارات مخصصة

-

🏭 الإنتاج الصغير والكبير على حد سواء

إذا كان عملك يحتاج إلى تشطيبات مطفية متميزة ومتكررة على الستانلس ستيل المرآوي، ستوفر هذه الآلة الوقت، تقلل الهدر، وتجعل أعمالك تبدو احترافية – في كل مرة.

المواصفات الفنية التي تحقق النتائج

| الميزة | لماذا هي مهمة |

|---|---|

| مساحة العمل: 1300×2500 مم | التعامل مع اللوحات الكبيرة دون إعادة وضعها |

| الليزر: JPT M7 / Guangzhi 100W | قوة عالية، تشطيب مطفي ناعم ومتسق |

| الطاولة: شفط بالنيليون | حماية السطح، منع الاهتزاز |

| نظام التتبع التلقائي | نظام “Engraving-on-the-Go” يضمن تشطيبًا مطفيًا مثاليًا على اللوحات المشوهة |

| العملية | بدون غبار، بدون مستهلكات، بدون فوضى |

لماذا تختار هذه الآلة؟

-

✅ تشطيب مطفي مثالي لكل لوحة – بدون خطوط، بدون خدوش

-

✅ التعامل مع الصفائح الكبيرة – أبواب المصاعد، الألواح الجدارية، الصفائح الزخرفية

-

✅ أنظف، أكثر أمانًا، وأرخص – لا رمل، لا غبار، لا تنظيف

-

✅ إنتاج أسرع – مؤتمت، دقيق، قابل للتكرار

-

✅ تحكم رقمي – نتائج متسقة، خطأ بشري أقل

⏳ توقف عن إضاعة الوقت بالطرق التقليدية. قم بالترقية إلى آلة السفع الرملي بالليزر للستانلس ستيل المرآوي واجعل لوحاتك تبدو مثالية في كل مرة.

آلة السفع الرملي بالليزر للستانلس ستيل المرآوي مثالية للشركات التي تبحث عن آلات سفع ليزر للستانلس ستيل المرآوي. مساحة العمل 1300×2500 مم، طاولة شفط بالنيليون، وليزر صناعي 100W يضمن نتائج عالية الجودة ومتسقة. سواء كنت تنهي أبواب المصاعد، الألواح الزخرفية، أو صفائح المطابخ، هذه الآلة توفر الوقت، تقلل الهدر، وتوفر تشطيبات مطفية احترافية – في كل مرة.

🚀 المزايا الرئيسية لآلة السفع الرملي بالليزر للستانلس ستيل المرآوي 1300×2500 مم

| الميزة | لماذا هي مهمة / الفائدة |

|---|---|

| تشطيب مرآوي مثالي في كل مرة | نظام “Engraving-on-the-Go” التلقائي يعوّض عن اللوحات المنحنية، ويضمن تشطيبات مطفية متسقة بدون خطوط أو مناطق خفيفة. |

| مساحة عمل كبيرة 1300×2500 مم | معالجة أبواب المصاعد كاملة، الألواح الزخرفية، أو صفائح المطابخ في مرة واحدة – بدون إعادة وضع، أخطاء أقل، إنتاجية أعلى. |

| خالي من الخدوش ودقيق | ليزر 100W JPT M7 / Guangzhi يقوم بتفتيت سطح المادة مع حماية الطبقة العاكسة، لضمان نتائج عالية الجودة. |

| معالجة مستقرة وخالية من الاهتزاز | طاولة شفط بالنيليون تثبت اللوحات بإحكام، تمنع الحركة، وتضمن دقة مطلقة في النمط. |

| خالي من الغبار وصديق للبيئة | بدون رمل، بدون حبيبات، بدون تنظيف. بيئة أنظف، تكاليف عمالة أقل، وأمان أعلى أثناء التشغيل. |

| كفاءة عالية وتوفير في التكاليف | المعالجة المؤتمتة تقلل الجهد اليدوي ووقت الإنتاج. بدون مستهلكات، بدون تكاليف تهوية، نفقات تشغيل منخفضة. |

| تطبيقات متعددة الاستخدامات | مثالية لـ لوحات المصاعد، الألواح الجدارية الزخرفية، صفائح المطابخ، الأعمال المعدنية المعمارية، الأنماط/الشعارات المخصصة. تناسب الإنتاج الصغير والكبير على حد سواء. |

| جودة قابلة للتكرار ومطابقة للمعايير الصناعية | التحكم الرقمي يضمن نتائج قابلة للتكرار 100٪، ويمنح عملائك تشطيبات مطفية متميزة باستمرار. |

💡 ملخص سريع / شعار تسويقي

“توقف عن السفع الرملي. ابدأ بالربح. لوحات الستانلس ستيل المرآوي المثالية، في كل مرة.”

🏭 تطبيقات آلة السفع الرملي بالليزر للستانلس ستيل المرآوي 1300×2500 مم

تعد هذه الآلة مثالية لأي عمل يحتاج إلى تشطيبات مطفية متميزة وقابلة للتكرار على الستانلس ستيل المرآوي. وتشمل التطبيقات الرئيسية ما يلي:

1️⃣ أبواب وداخلية المصاعد

-

تحقيق تشطيبات مطفية متسقة وعالية الجودة للوحات المصاعد الكبيرة

-

التعامل مع اللوحات كاملة الحجم دون إعادة وضعها، لضمان الكفاءة والثبات

2️⃣ الألواح الجدارية الزخرفية

-

مثالية للتكسية المعدنية المعمارية والداخلية

-

تمكّنك من إنشاء أنماط أو ملمس مخصص مع الحفاظ على سطح مطفي مثالي

3️⃣ صفائح مطابخ الستانلس ستيل

-

مناسبة للحوائط الخلفية للمطابخ، أسطح العمل، والأجهزة

-

توفر تشطيبًا نظيفًا وخاليًا من الخدوش، جاهز للتركيب أو المعالجة الإضافية

4️⃣ الأعمال المعدنية المعمارية والداخلية

-

مناسبة للمشاريع التجارية والسكنية التي تتطلب تشطيبات راقية

-

تتعامل مع اللوحات الكبيرة أو الأشكال غير المنتظمة مع الحفاظ على جودة السطح

5️⃣ الأنماط والشعارات المخصصة

-

تدعم العلامات التجارية أو التصاميم الزخرفية على أسطح الستانلس ستيل

-

يضمن نظام التتبع التلقائي الدقة على اللوحات المنحنية أو المشوهة

6️⃣ الإنتاج الصغير والكبير

-

مرنة بما يكفي للطلبات المخصصة والإنتاج الصناعي الكبير

-

تقلل من العمالة وهدر المواد، مما يزيد من الكفاءة العامة

🔹 ملخص

سواء كنت تصنع أبواب المصاعد، الألواح الجدارية الزخرفية، صفائح المطابخ، أو الأعمال المعدنية المعمارية المخصصة، تضمن هذه الآلة تشطيبات مطفية متسقة وخالية من الخدوش بدون أي غبار، مما يعزز الجودة والإنتاجية.

❓ الأسئلة المتكررة – آلة السفع الرملي بالليزر للستانلس ستيل المرآوي (1300×2500 مم)

س1: ما أنواع ألواح الستانلس ستيل التي يمكن لهذه الآلة معالجتها؟

ج: تم تصميم هذه الآلة لمعالجة ألواح الستانلس ستيل المرآوي، بما في ذلك أبواب المصاعد، الألواح الجدارية الزخرفية، صفائح المطابخ، والأعمال المعدنية المعمارية. يمكنها التعامل مع الإنتاج الصغير والكبير مع تشطيبات مطفية متسقة.

س2: ما حجم مساحة العمل؟

ج: مساحة العمل 1300×2500 مم تسمح بمعالجة اللوحات كاملة الحجم دون إعادة وضعها، مما يقلل الأخطاء ويزيد الإنتاجية لللوحات الكبيرة.

س3: ما قوة الليزر المستخدمة في الآلة؟

ج: تستخدم الآلة ليزر فايبر 100W JPT M7 أو Guangzhi، لتوفير طاقة دقيقة تحقق تشطيبات مطفية ناعمة وخالية من الخدوش على الستانلس ستيل المرآوي.

س4: كيف يعمل نظام التتبع التلقائي؟

ج: يقوم نظام “Engraving-on-the-Go” التلقائي بضبط تركيز الليزر تلقائيًا ليتبع الانحناءات أو التشوهات الطفيفة في اللوحة، مما يضمن عمق مطفي متساوٍ على كامل السطح.

س5: هل العملية نظيفة وآمنة؟

ج: نعم. على عكس السفع الرملي التقليدي، هذه الآلة خالية من الغبار، ولا تحتاج إلى رمل أو مستهلكات، وتقلل من عمليات التنظيف. طاولة الشفط بالنيليون تثبت اللوحات وتقلل الاهتزاز، مما يضمن السلامة والدقة.

س6: هل يمكنها معالجة الأنماط أو الشعارات المخصصة؟

ج: بالتأكيد. يسمح نظام التحكم الرقمي بنقش أنماط، ملمس، أو شعارات مخصصة بدقة عالية على أسطح الستانلس ستيل المرآوي.

س7: ما سرعة عملية الإنتاج؟

ج: مساحة العمل الكبيرة والنظام الآلي لليزر يزيدان الإنتاجية بشكل كبير، مما يتيح معالجة اللوحات كاملة في تمريرة واحدة. سرعة الإنتاج أسرع بكثير من السفع الرملي التقليدي، مع نتائج متسقة في كل مرة.

س8: ما الصيانة المطلوبة؟

ج: الصيانة قليلة مقارنة بالسفع الرملي التقليدي. لا يوجد رمل أو حبيبات للاستبدال، والليزر الفايبر متين للغاية. يُنصح بإجراء فحوصات دورية للطاولة الشفطية ومحاذاة الليزر لأداء أمثل.

س9: هل تناسب الطلبات الصغيرة والكبيرة؟

ج: نعم. الآلة مرنة للمشاريع المخصصة الصغيرة وكذلك للإنتاج الصناعي الكبير، مع ضمان نتائج قابلة للتكرار ومتسقة في كل مرة.

س10: ما الفوائد الرئيسية لاستخدام هذه الآلة؟

ج: الفوائد الرئيسية تشمل:

-

✅ تشطيب مطفي خالٍ من الخدوش على الستانلس ستيل المرآوي

-

✅ معالجة اللوحات الكبيرة (1300×2500 مم)

-

✅ نتائج مؤتمتة وقابلة للتكرار بنظام “Engraving-on-the-Go”

-

✅ تشغيل خالٍ من الغبار، تقليل العمالة، وخفض التكاليف

-

✅ مثالية لـ أبواب المصاعد، الألواح الزخرفية، المطابخ، والأعمال المعدنية المعمارية

آلة تعليم الليزر وحفر الزجاج المُعالج بالسفع الرملي

اطلب عرض سعر لآلة وسم الليزر الفايبر

تمتلك SISMAR LASER آلات ليزر فايبر وحلولاً أخرى مناسبة للعديد من التطبيقات الصناعية. يمكن لحلولنا أن تكون ترقية ممتازة لنظام الوسم بالليزر الحالي لديك، أو خيارًا مثاليًا لشراء أول آلة ليزر.

اطلب عرض سعر لآلة وسم ليزر فايبر عالية الجودة تتجاوز توقعاتك. كما يمكنك أيضًا حجز عرض توضيحي لمعرفة كيفية عمل الوسم بالليزر الفايبر.

مرحبًا بكم في SISMAR Laser. يسعدنا جدًا الإجابة عن أي أسئلة لديكم حول آلات الوسم والقطع بليزر الفايبر.

Станок лазерной пескоструйной обработки зеркальной нержавеющей стали (1300×2500 мм)

December 2, 2025 /0 Comments/in Language /by linda

Станок лазерной пескоструйной обработки зеркальной нержавеющей стали (1300×2500 мм)

Делайте зеркальные панели из нержавеющей стали идеальными — каждый раз.

Станок лазерной пескоструйной обработки зеркальной нержавеющей стали (1300×2500 мм)

Улучшите процесс отделки нержавеющей стали с помощью нашего станка лазерной пескоструйной обработки зеркальной нержавеющей стали размером 1300×2500 мм. Предназначенный для лифтовых панелей, декоративных стеновых панелей, кухонных листов и архитектурных металлических элементов, этот станок обеспечивает безупречное матовое покрытие без царапин каждый раз.

Оснащён волоконным лазером JPT M7 / Guangzhi мощностью 100 Вт, вакуумным столом с нейлоновой поверхностью и системой автоматического следования «Engraving-on-the-Go», которая автоматически подстраивается под деформированные или изогнутые панели, обеспечивая идеальную однородность покрытия.

Забудьте о песке, пыли и уборке после работы, и наслаждайтесь более быстрой производительностью, снижением трудозатрат и стабильным высоким качеством результатов — идеально подходит как для малых партий, так и для крупных промышленных проектов.

Фотографии станка лазерной пескоструйной обработки зеркальной стали

🔹 Прекратите бороться с неровными матовыми покрытиями!

Если вы когда-либо работали с зеркальной нержавеющей сталью, вы знаете, как это раздражает:

⚡ Одна панель выглядит идеально, а следующая покрыта полосами.

⚡ Традиционная пескоструйная обработка создает пыль, беспорядок и потери материала.

⚡ Обработка больших панелей — это трудоемко и сложно добиться ровного покрытия.

Эта лазерная пескоструйная машина 1300×2500 мм создана для профессионалов, которым нужны идеальные матовые поверхности на зеркальной нержавеющей стали, дверях лифтов, кухонных листах и декоративных панелях — каждый раз.

🌟 Почему эта машина имеет значение

Традиционные методы медленные, грязные и непостоянные. Наше лазерное решение меняет правила игры:

✅ Большая рабочая зона 1300×2500 мм → обрабатывайте панели полного размера за один проход, без перекладывания.

✅ Вакуумный стол из нейлона → удерживает листы на месте, защищает поверхность и гарантирует равномерное матовое покрытие.

✅ Лазер JPT M7 / Guangzhi 100 Вт → стабильная энергия для гладких, премиальных матовых результатов.

✅ Система Auto-following «Engraving-on-the-Go» → автоматически подстраивается под изгибы и деформации, обеспечивая идеальную однородность покрытия.

✅ Без песка, без пыли, без уборки → безопаснее, чище и дешевле традиционного пескоструя.

💡 Подумайте об этом как о точности, скорости и надежности в одной машине.

⚙️ Как это работает

-

Разместите вашу панель из зеркальной нержавеющей стали на вакуумном столе из нейлона.

-

Лазер автоматически следует за панелью, подстраиваясь под изгибы или деформации.

-

Получите тонкое, равномерное матовое покрытие, как при традиционной пескоструйной обработке — быстрее, чище и полностью цифрово.

-

Панели готовы к установке или доставке. Никакой пыли, царапин и догадок.

🎯 Идеально для этих применений

-

Двери и панели лифтов

-

Декоративные стеновые панели

-

Кухонные листы из нержавеющей стали

-

Архитектурные и интерьерные металлические элементы

-

Индивидуальные узоры или логотипы

-

Малые партии и массовое производство

Если вашему бизнесу нужны повторяемые, премиальные матовые покрытия на зеркальной нержавеющей стали, эта машина сэкономит время, уменьшит потери и придаст работе профессиональный вид — каждый раз.

🛠️ Технические характеристики, которые дают результат

| Характеристика | Зачем это важно |

|---|---|

| Рабочая зона: 1300×2500 мм | Обработка больших панелей без перекладывания |

| Лазер: JPT M7 / Guangzhi 100 Вт | Высокая мощность, гладкое и стабильное матовое покрытие |

| Стол: вакуумный из нейлона | Защищает поверхность, предотвращает вибрацию |

| Система Auto-following | Автоматическая подстройка под изгибы, идеальное матовое покрытие |

| Процесс | Без пыли, без расходных материалов, чисто и безопасно |

✅ Почему стоит выбрать эту лазерную пескоструйную машину

-

Идеальное матовое покрытие на каждой панели — ни полос, ни царапин

-

Обработка больших листов — двери лифтов, стеновые панели, декоративные панели

-

Чище, безопаснее, дешевле — без песка, пыли и уборки

-

Более быстрая производительность — автоматизировано, точно и повторяемо

-

Цифровое управление — стабильные результаты, меньше человеческой ошибки

⏩ Перестаньте тратить время на традиционные методы. Обновитесь до лазерной пескоструйной машины для зеркальной нержавеющей стали и делайте ваши панели безупречными каждый раз.

Эта машина идеальна для компаний, ищущих лазерные пескоструйные станки для зеркальной нержавеющей стали. Рабочая зона 1300×2500 мм, вакуумный стол из нейлона и индустриальный лазер 100 Вт гарантируют стабильный, высококачественный результат. Независимо от того, обрабатываете ли вы двери лифтов, декоративные панели или кухонные листы, эта машина сэкономит время, уменьшит отходы и обеспечит профессиональное матовое покрытие — каждый раз.

🚀 Основные преимущества лазерной пескоструйной машины для зеркальной нержавеющей стали 1300×2500 мм

| Преимущество | Почему это важно / Выгода |

|---|---|

| Безупречное зеркальное покрытие каждый раз | Система Auto-following «Engraving-on-the-Go» компенсирует деформации панелей, обеспечивая равномерное матовое покрытие без полос и неровностей. |

| Большая рабочая зона 1300×2500 мм | Обработка панелей полного размера — двери лифтов, декоративные панели или кухонные листы — за один проход без перекладывания, с меньшим количеством ошибок и высокой производительностью. |

| Без царапин и с высокой точностью | Волоконный лазер 100W JPT M7 / Guangzhi аккуратно обрабатывает поверхность, сохраняя отражающий базовый слой, обеспечивая премиальное качество. |

| Стабильная обработка без вибраций | Вакуумный стол из нейлона надежно фиксирует панели, предотвращая смещение и гарантируя идеальное повторение узора. |

| Без пыли и экологично | Нет песка, нет мусора, нет уборки. Чистая рабочая среда, снижение затрат на труд, безопасная эксплуатация. |

| Высокая эффективность и экономия | Автоматизированная обработка сокращает ручной труд и время производства. Без расходных материалов, без затрат на вентиляцию, снижение операционных расходов. |

| Универсальные применения | Идеально для дверей лифтов, декоративных стеновых панелей, кухонных листов, архитектурных металлических элементов, индивидуальных узоров и логотипов. Подходит как для малых партий, так и для массового производства. |

| Повторяемое промышленное качество | Цифровое управление обеспечивает 100% воспроизводимые результаты, предоставляя вашим клиентам стабильное премиальное матовое покрытие каждый раз. |

⚡ Кратко / Слоган для маркетинга

«Перестаньте использовать пескоструй. Начните зарабатывать. Безупречные зеркальные панели из нержавеющей стали — каждый раз.»

🏭 Применение лазерной пескоструйной машины для зеркальной нержавеющей стали 1300×2500 мм

Эта машина идеально подходит для любого бизнеса, которому нужны премиальные и повторяемые матовые покрытия на зеркальной нержавеющей стали. Основные сферы применения:

1️⃣ Интерьеры и двери лифтов

-

Достижение равномерного, высококачественного матового покрытия на больших панелях лифтов.

-

Обработка панелей полного размера без перекладывания, обеспечивая эффективность и стабильность результата.

2️⃣ Декоративные стеновые панели

-

Идеально для архитектурной и интерьерной металлической облицовки.

-

Позволяет создавать индивидуальные текстуры и узоры, сохраняя безупречное матовое покрытие.

3️⃣ Кухонные листы из нержавеющей стали

-

Подходит для кухонных фартуков, столешниц и бытовой техники.

-

Обеспечивает чистую, без царапин поверхность, готовую к установке или дальнейшей обработке.

4️⃣ Архитектурные и интерьерные металлические изделия

-

Применимо для коммерческих и жилых проектов, где требуются высококачественные покрытия.

-

Обрабатывает крупные панели или нестандартные формы, сохраняя качество поверхности.

5️⃣ Индивидуальные узоры и логотипы

-

Поддержка брендирования и декоративного дизайна на нержавеющей стали.

-

Система Auto-following гарантирует точность на изогнутых или деформированных панелях.

6️⃣ Малые партии и массовое производство

-

Достаточно гибкая для индивидуальных заказов и крупносерийного промышленного производства.

-

Сокращает трудозатраты и потери материала, повышая общую эффективность.

⚡ Краткое резюме

Независимо от того, производите ли вы двери лифтов, декоративные стеновые панели, кухонные листы или индивидуальные архитектурные изделия, эта машина обеспечивает повторяемое, безупречное матовое покрытие без пыли, повышая качество и производительность вашего производства.

❓ FAQ – Лазерная пескоструйная машина для зеркальной нержавеющей стали (1300×2500 мм)

Q1: Какие типы панелей из нержавеющей стали можно обрабатывать на этой машине?

A: Машина предназначена для зеркальных панелей из нержавеющей стали, включая двери лифтов, декоративные стеновые панели, кухонные листы и архитектурные металлические изделия. Подходит как для малосерийного, так и для крупносерийного производства с равномерным матовым покрытием.

Q2: Какова рабочая зона машины?

A: Рабочая зона 1300×2500 мм позволяет обрабатывать панель целиком без перекладывания, что снижает ошибки и увеличивает производительность при работе с крупными панелями.

Q3: Какая мощность лазера используется?

A: Машина оснащена волоконным лазером JPT M7 или Guangzhi 100 Вт, обеспечивающим точную подачу энергии для гладкого, без царапин матового покрытия на зеркальной нержавеющей стали.

Q4: Как работает система Auto-following?

A: Система Auto-following «Engraving-on-the-Go» автоматически подстраивает фокус лазера, чтобы повторять легкие изгибы или деформации панели, обеспечивая равномерную глубину матового покрытия по всей поверхности.

Q5: Процесс чистый и безопасный?

A: Да. В отличие от традиционного пескоструя, эта машина без пыли, не требует песка или расходных материалов и минимизирует уборку. Вакуумный нейлоновый стол удерживает панели на месте и снижает вибрацию, обеспечивая безопасность и точность обработки.

Q6: Можно ли обрабатывать индивидуальные узоры или логотипы?

A: Конечно. Цифровая система управления позволяет гравировать кастомные текстуры, узоры или логотипы с высокой точностью на поверхности зеркальной нержавеющей стали.

Q7: Насколько быстрый процесс производства?

A: Большая рабочая зона и автоматизированная лазерная система значительно увеличивают производительность. Панели обрабатываются за один проход, что быстрее традиционного пескоструя и с постоянно высоким качеством.

Q8: Какое требуется обслуживание?

A: Обслуживание минимальное по сравнению с традиционным пескоструем. Песок или абразив заменять не нужно, а волоконный лазер обладает высокой долговечностью. Рекомендуется регулярно проверять вакуумный стол и выравнивание лазера для оптимальной работы.

Q9: Подходит ли машина для малых и больших заказов?

A: Да. Машина универсальна как для малосерийных заказов, так и для крупносерийного промышленного производства, обеспечивая постоянные и воспроизводимые результаты каждый раз.

Q10: Каковы основные преимущества использования этой машины?

A: Основные преимущества:

-

Безупречное, без царапин матовое покрытие на зеркальной нержавеющей стали

-

Обработка больших панелей (1300×2500 мм)

-

Автоматизированные, повторяемые результаты с системой «Engraving-on-the-Go»

-

Без пыли, снижение трудозатрат и затрат на производство

-

Идеально для дверей лифтов, декоративных панелей, кухонных листов и архитектурных металлических изделий

Станок лазерной гравировки и маркировки матового стекла

Запросить коммерческое предложение на волоконный лазерный маркировочный станок

Компания SISMAR LASER предлагает волоконные лазерные станки и другие решения для множества промышленных применений. Наши решения могут стать отличным обновлением вашей существующей системы лазерной маркировки или идеальным выбором для вашей первой лазерной машины.

Запросите коммерческое предложение на высококачественный волоконный лазерный маркировочный станок, который превзойдет ваши ожидания. Вы также можете записаться на демонстрацию, чтобы увидеть, как работает волоконная лазерная маркировка.

Добро пожаловать в SISMAR Laser! Мы с радостью ответим на любые ваши вопросы о наших волоконных лазерных станках для маркировки и резки.

Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável 1300×2500 mm

December 1, 2025 /0 Comments/in Language /by linda

Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável (1300×2500 mm)

Deixe os Painéis de Aço Inoxidável Espelhado Perfeitos, Toda Vez.

Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável (1300×2500 mm)

Atualize seu processo de acabamento em aço inoxidável com nossa Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável 1300×2500 mm. Projetada para painéis de elevadores, painéis decorativos de parede, chapas de cozinha e trabalhos metálicos arquitetônicos, esta máquina proporciona acabamentos mate impecáveis e sem riscos todas as vezes.

Equipado com um laser de fibra 100W JPT M7 / Guangzhi, uma mesa de sucção a vácuo de nylon e o sistema Auto-following “Engraving-on-the-Go”, ajusta automaticamente para painéis deformados ou curvados, garantindo uniformidade perfeita.

Diga adeus à areia, poeira e limpeza bagunçada, e aproveite produção mais rápida, menor custo de mão de obra e resultados de alta qualidade e repetíveis—ideal tanto para pequenos lotes quanto para projetos industriais de grande escala.

Fotos da Máquina de Jateamento a Laser para Espelhos

🚀 Pare de Lutar com Acabamentos Mate Desiguais

Se você já trabalhou com aço inoxidável espelhado, sabe como pode ser frustrante:

-

✖️ Um painel parece perfeito, o próximo tem riscos ou manchas

-

✖️ O jateamento tradicional cria poeira, sujeira e desperdício de material

-

✖️ Painéis grandes são difíceis de manusear e terminar de forma uniforme

A Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável 1300×2500 mm foi projetada para profissionais que precisam de acabamentos mate perfeitos em painéis de aço inoxidável espelhado, portas de elevadores, chapas de cozinha e painéis decorativos, toda vez.

🔥 Por Que Esta Máquina é Importante

Os métodos tradicionais são lentos, bagunçados e inconsistentes. Nossa solução de jateamento a laser muda completamente o jogo:

-

✅ Grande área de trabalho 1300×2500 mm → processa painéis completos de uma só vez, sem reposicionamento.

-

✅ Mesa de sucção a vácuo de nylon → mantém os painéis estáveis, protege a superfície e garante acabamento mate uniforme.

-

✅ Laser JPT M7 / Guangzhi 100W → energia consistente para acabamentos suaves e premium.

-

✅ Sistema Auto-following “Engraving-on-the-Go” → ajusta automaticamente pequenas deformações ou curvaturas, mantendo o acabamento perfeitamente uniforme.

-

✅ Sem areia, sem poeira, sem limpeza → mais seguro, mais limpo e mais econômico que o jateamento tradicional.

💡 Pense em precisão, velocidade e confiabilidade, tudo em uma única máquina.

⚡ Como Funciona

-

Coloque o painel de aço inoxidável espelhado na mesa de sucção a vácuo de nylon.

-

O laser segue automaticamente o painel, ajustando-se às curvas ou deformações.

-

Um acabamento mate fino e uniforme é criado, como o jateamento tradicional — mas mais rápido, limpo e totalmente digital.

-

Os painéis estão prontos para instalação ou entrega. Sem poeira. Sem riscos. Sem adivinhação.

🏆 Perfeito Para Estas Aplicações

-

Portas e painéis de elevadores

-

Painéis decorativos de parede

-

Chapas de cozinha de aço inoxidável

-

Trabalhos metálicos arquitetônicos e interiores

-

Padrões ou logotipos personalizados

-

Produção de pequenos lotes e grande escala

Se sua empresa precisa de acabamentos mate premium e repetíveis em aço inoxidável espelhado, esta máquina economiza tempo, reduz desperdício e faz seu trabalho parecer profissional — sempre.

⚙️ Especificações Técnicas que Entregam Resultados

| Recurso | Por Que Importa |

|---|---|

| Área de trabalho: 1300×2500 mm | Manuseia painéis grandes sem reposicionamento |

| Laser: JPT M7 / Guangzhi 100W | Alta potência, acabamento mate suave e consistente |

| Mesa: Sucção a vácuo de nylon | Protege a superfície, evita vibrações |

| Sistema Auto-following | Garante acabamento mate perfeito em painéis deformados |

| Processo | Sem poeira, sem consumíveis, sem bagunça |

✅ Por Que Escolher Esta Máquina de Jateamento a Laser

-

Acabamento mate perfeito, em cada painel — sem riscos, sem arranhões

-

Manuseio de painéis grandes — portas de elevadores, painéis de parede, chapas decorativas

-

Mais limpo, seguro e econômico — sem areia, sem poeira, sem limpeza

-

Produção mais rápida — automatizada, precisa e repetível

-

Controle digital — resultados consistentes, menos erros humanos

⏩ Pare de perder tempo com métodos tradicionais. Atualize para a Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável e faça com que seus painéis fiquem impecáveis, toda vez.

A Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável é perfeita para empresas que buscam máquinas de jateamento a laser para aço inoxidável espelhado. Sua área de trabalho de 1300×2500 mm, mesa de sucção a vácuo de nylon e laser industrial de 100W garantem resultados consistentes e de alta qualidade. Seja para acabamento de portas de elevadores, painéis decorativos ou chapas de cozinha, esta máquina economiza tempo, reduz desperdícios e entrega acabamentos mate de nível profissional — sempre.

🚀 Vantagens Principais da Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável 1300×2500 mm

| Vantagem | Por Que Importa / Benefício |

|---|---|

| Acabamento Espelhado Impecável Sempre | O sistema Auto-following “Engraving-on-the-Go” compensa painéis deformados, entregando acabamentos mate uniformes sem riscos ou pontos rasos. |

| Grande Área de Trabalho 1300×2500 mm | Processa portas de elevador, painéis decorativos ou chapas de cozinha completas de uma vez — sem reposicionamento, menos erros e maior produtividade. |

| Sem Riscos e Preciso | O laser de fibra 100W JPT M7 / Guangzhi atomiza a superfície enquanto protege a camada refletiva, garantindo resultados premium de alta qualidade. |

| Processamento Estável e Sem Vibrações | A mesa de sucção a vácuo de nylon mantém os painéis firmes, prevenindo movimentos e garantindo fidelidade perfeita do padrão. |

| Sem Poeira e Sustentável | Sem areia, sem resíduos, sem limpeza. Ambiente mais limpo, menor custo de mão de obra e operação mais segura. |

| Alta Eficiência e Economia | O processamento automatizado reduz trabalho manual e tempo de produção. Sem consumíveis, sem custo de ventilação, menores despesas operacionais. |

| Aplicações Versáteis | Ideal para painéis de elevador, painéis decorativos de parede, chapas de cozinha, trabalhos metálicos arquitetônicos, padrões/logos personalizados. Funciona para pequenos lotes e produção em larga escala. |

| Qualidade Reproduzível de Nível Industrial | O controle digital garante resultados 100% reproduzíveis, oferecendo aos seus clientes acabamentos mate premium consistentes toda vez. |

💡 Resumo Rápido / Lema para Marketing

“Pare de Jatear. Comece a Lucrar. Painéis de Aço Inoxidável Espelhado Impecáveis, Sempre.”

🏭 Aplicações da Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável 1300×2500 mm

Esta máquina é ideal para qualquer negócio que precise de acabamentos mate premium e repetíveis em aço inoxidável espelhado. Suas principais aplicações incluem:

1️⃣ Interiores e Portas de Elevadores

-

Alcance acabamentos mate uniformes e de alta qualidade em painéis grandes de elevadores.

-

Processa painéis completos sem reposicionamento, garantindo eficiência e consistência.

2️⃣ Painéis Decorativos de Parede

-

Perfeita para revestimentos metálicos arquitetônicos e interiores.

-

Permite texturas ou padrões personalizados enquanto mantém uma superfície mate impecável.

3️⃣ Chapas de Aço Inoxidável para Cozinhas

-

Ideal para backsplash, bancadas e eletrodomésticos de cozinha.

-

Proporciona um acabamento limpo e sem riscos, pronto para instalação ou processamento adicional.

4️⃣ Trabalhos Metálicos Arquitetônicos e Interiores

-

Adequada para projetos comerciais e residenciais que exijam acabamentos de alta qualidade.

-

Manipula painéis grandes ou formas irregulares, preservando a qualidade da superfície.

5️⃣ Padrões e Logotipos Personalizados

-

Suporta branding ou designs decorativos em superfícies de aço inoxidável.

-

O sistema Auto-following garante precisão mesmo em painéis curvados ou deformados.

6️⃣ Produção de Pequenos Lotes e em Larga Escala

-

Flexível para pedidos personalizados e produção industrial em grande escala.

-

Reduz mão de obra e desperdício de material, aumentando a eficiência total.

✅ Resumo

Se você fabrica portas de elevadores, painéis decorativos de parede, chapas de cozinha ou trabalhos metálicos arquitetônicos personalizados, esta máquina garante acabamentos mate consistentes, sem riscos e sem poeira, aumentando a qualidade e produtividade do seu negócio.

❓ Perguntas Frequentes – Máquina de Jateamento a Laser para Espelhos de Aço Inoxidável (1300×2500 mm)

Q1: Quais tipos de painéis de aço inoxidável esta máquina pode processar?

A: Esta máquina foi projetada para painéis de aço inoxidável espelhado, incluindo portas de elevadores, painéis decorativos de parede, chapas de cozinha e trabalhos metálicos arquitetônicos. Pode processar tanto pequenos lotes quanto produção em larga escala, garantindo acabamentos mate consistentes.

Q2: Qual é o tamanho da área de trabalho?

A: A área de trabalho de 1300×2500 mm permite processar painéis completos sem reposicionamento, reduzindo erros e aumentando a produtividade em painéis grandes.

Q3: Qual potência de laser a máquina utiliza?

A: Utiliza um laser de fibra 100W JPT M7 ou Guangzhi, fornecendo energia precisa para acabamentos mate suaves e sem riscos em aço inoxidável espelhado.

Q4: Como funciona o sistema Auto-following?

A: O sistema Auto-following “Engraving-on-the-Go” ajusta automaticamente o foco do laser para seguir pequenas deformações ou curvaturas no painel. Isso garante uma profundidade mate uniforme em toda a superfície.

Q5: O processo é limpo e seguro?

A: Sim. Diferente do jateamento tradicional, esta máquina é livre de poeira, não requer areia nem consumíveis, e minimiza a limpeza. A mesa de sucção a vácuo de nylon mantém os painéis estáveis e reduz vibrações, garantindo segurança e precisão.

Q6: Pode lidar com padrões ou logotipos personalizados?

A: Absolutamente. O sistema de controle digital permite gravar texturas, padrões ou logotipos personalizados com alta precisão em superfícies de aço inoxidável espelhado.

Q7: Qual a velocidade do processo de produção?

A: A grande área de trabalho e o sistema de laser automatizado aumentam significativamente a produtividade, permitindo processar painéis completos em uma única passada. A produção é muito mais rápida que o jateamento tradicional, com resultados consistentes todas as vezes.

Q8: Qual manutenção é necessária?

A: A manutenção é mínima em comparação com o jateamento tradicional. Não há areia ou abrasivo para substituir, e o laser de fibra é altamente durável. Recomenda-se verificar periodicamente a mesa de vácuo e o alinhamento do laser para desempenho ideal.

Q9: É adequada para pedidos pequenos e grandes?

A: Sim. A máquina é versátil, apta para projetos personalizados de pequenos lotes e produção industrial em grande escala, fornecendo resultados consistentes e repetíveis em todas as situações.

Q10: Quais são os principais benefícios de usar esta máquina?

-

Acabamento mate impecável e sem riscos em aço inoxidável espelhado

-

Processamento de painéis grandes (1300×2500 mm)

-

Resultados automatizados e repetíveis com o sistema “Engraving-on-the-Go”

-

Operação sem poeira, redução de mão de obra e menores custos

-

Ideal para portas de elevadores, painéis decorativos, cozinhas e trabalhos metálicos arquitetônicos

Máquina de Gravação a Laser para Vidro Jateado e Marcação a Laser

Solicite um Orçamento para uma Máquina de Marcação a Laser de Fibra

A SISMAR LASER oferece máquinas de marcação a laser de fibra e outras soluções para diversas aplicações industriais. Nossas soluções podem ser um upgrade para seu sistema de marcação a laser existente ou uma excelente escolha para sua primeira máquina a laser.

Solicite um orçamento para uma máquina de marcação a laser de fibra de alta qualidade que supere suas expectativas. Você também pode agendar uma demonstração para ver como funciona a marcação a laser de fibra.

Bem-vindo à SISMAR Laser. Ficamos muito felizes em responder a quaisquer perguntas sobre nossas máquinas de marcação/corte a laser de fibra.

Máquina láser de arenado para espejos de acero inoxidable de 1300×2500 mm

December 1, 2025 /0 Comments/in Language /by linda

Máquina láser de arenado para espejos de acero inoxidable (1300×2500 mm)

Haz que los paneles de acero inoxidable espejado queden perfectos, siempre.

Máquina Láser de Arenado para Espejos de Acero Inoxidable (1300×2500 mm)

Actualice su proceso de acabado en acero inoxidable con nuestra máquina láser de arenado para espejos de acero inoxidable de 1300×2500 mm. Diseñada para paneles de ascensores, paneles decorativos de pared, láminas de cocina y trabajos metálicos arquitectónicos, esta máquina ofrece acabados mates impecables y sin rayaduras en todo momento.

Equipada con un láser de fibra JPT M7 / Guangzhi de 100W, una mesa de succión al vacío con superficie de nailon y el sistema automático de seguimiento “Engraving-on-the-Go”, ajusta automáticamente las deformaciones o curvaturas de las láminas, garantizando una uniformidad perfecta.

Despídase de la arena, el polvo y la limpieza desordenada, y disfrute de una producción más rápida, menores costos de mano de obra y resultados de alta calidad repetibles—ideal tanto para pequeños lotes como para proyectos industriales de gran escala.

Fotos de la máquina de arenado láser para espejos

🚀 Deja de Luchar con Acabados Mate Desiguales

Si alguna vez has trabajado con acero inoxidable espejado, sabes lo frustrante que puede ser:

-

✖️ Un panel se ve perfecto, el siguiente tiene rayas.

-

✖️ El arenado tradicional crea polvo, suciedad y desperdicio de material.

-

✖️ Los paneles grandes son difíciles de manejar y terminar de manera uniforme.

Nuestra Máquina Láser de Arenado para Espejos de Acero Inoxidable (1300×2500 mm) está diseñada para profesionales que necesitan acabados mate perfectos en paneles de acero inoxidable espejado, puertas de ascensores, láminas de cocina y paneles decorativos, cada vez.

🔥 Por Qué Esta Máquina Marca la Diferencia

Los métodos tradicionales son lentos, desordenados e inconsistentes. Nuestra solución de arenado láser cambia las reglas del juego:

-

✅ Gran área de trabajo de 1300×2500 mm → procesa paneles completos de una sola vez, sin necesidad de reposicionarlos.

-

✅ Mesa de succión al vacío de nailon → mantiene las láminas estables, protege la superficie y garantiza un acabado mate uniforme.

-

✅ Láser JPT M7 / Guangzhi de 100W → energía consistente para resultados mate suaves y de alta calidad.

-

✅ Sistema Auto-following “Engraving-on-the-Go” → ajusta automáticamente las curvas o deformaciones, manteniendo un acabado perfectamente uniforme.

-

✅ Sin arena, sin polvo, sin limpieza → más seguro, más limpio y más económico que el arenado tradicional.

💡 Piensa en precisión, velocidad y fiabilidad, todo en una sola máquina.

⚡ Cómo Funciona

-

Coloca tu panel de acero inoxidable espejado en la mesa de succión al vacío de nailon.

-

El láser sigue automáticamente el panel, ajustándose a curvas o deformaciones.

-

Se crea un acabado mate fino y uniforme, como el arenado tradicional, pero más rápido, limpio y totalmente digital.

-

Los paneles están listos para instalar o entregar. Sin polvo. Sin rayaduras. Sin adivinanzas.

🏆 Aplicaciones Perfectas

-

Puertas y paneles de ascensores

-

Paneles decorativos de pared

-

Láminas de cocina de acero inoxidable

-

Trabajos metálicos arquitectónicos e interiores

-

Patrones personalizados o logotipos

-

Producción de pequeños lotes o producción masiva

Si tu negocio necesita acabados mate premium y repetibles en acero inoxidable espejado, esta máquina ahorra tiempo, reduce desperdicios y hace que tu trabajo luzca profesional, cada vez.

⚙️ Especificaciones Técnicas que Garantizan Resultados

| Característica | Por Qué Importa |

|---|---|

| Área de trabajo: 1300×2500 mm | Maneja paneles grandes sin reposicionamiento |

| Láser: JPT M7 / Guangzhi 100W | Alta potencia, acabado mate suave y consistente |

| Mesa: Succión al vacío de nailon | Protege la superficie, evita vibraciones |

| Sistema Auto-following | Ajusta automáticamente “Engraving-on-the-Go” para paneles deformados |

| Proceso | Sin polvo, sin consumibles, sin desorden |

✅ Por Qué Elegir Esta Máquina Láser de Arenado

-

Acabado mate perfecto, en cada panel – sin rayas, sin rayaduras

-

Manejo de láminas grandes – paneles de ascensores, paneles de pared, láminas decorativas

-

Más limpio, seguro y económico – sin arena, sin polvo, sin limpieza

-

Producción más rápida – automatizada, precisa y repetible

-

Control digital – resultados consistentes, menos errores humanos

⏩ Deja de perder tiempo con métodos tradicionales. Actualiza a la Máquina Láser de Arenado para Espejos de Acero Inoxidable y haz que tus paneles luzcan impecables cada vez.

La Máquina Láser de Arenado para Espejos de Acero Inoxidable es perfecta para empresas que buscan máquinas láser de arenado para acero inoxidable espejado. Su área de trabajo de 1300×2500 mm, mesa de vacío de nailon y láser industrial de 100W aseguran resultados consistentes y de alta calidad. Ya sea que estés terminando puertas de ascensor, paneles decorativos o láminas de cocina, esta máquina ahorra tiempo, reduce desperdicios y entrega acabados mate de nivel profesional, siempre.

🚀 Ventajas Clave de la Máquina Láser de Arenado para Espejos de Acero Inoxidable 1300×2500 mm

| Ventaja | Por Qué Importa / Beneficio |

|---|---|

| Acabado Espejado Impecable Cada Vez | El sistema automático “Engraving-on-the-Go” compensa paneles deformados, entregando acabados mate uniformes sin rayas ni zonas poco profundas. |

| Gran Área de Trabajo 1300×2500 mm | Procesa puertas de ascensor, paneles decorativos o láminas de cocina completas de una sola vez—sin reposicionamiento, menos errores, mayor productividad. |

| Precisión y Sin Rayaduras | El láser de fibra 100W JPT M7 / Guangzhi atomiza la superficie mientras protege la capa reflectante, garantizando resultados de calidad premium. |

| Procesamiento Estable y Sin Vibraciones | La mesa de succión al vacío de nailon mantiene los paneles firmes, evitando movimientos y asegurando fidelidad perfecta del patrón. |

| Sin Polvo y Ecológico | Sin arena, sin residuos, sin limpieza. Ambiente más limpio, menores costos de mano de obra y operación más segura. |

| Alta Eficiencia y Ahorro de Costos | El procesamiento automatizado reduce el trabajo manual y el tiempo de producción. Sin consumibles, sin costos de ventilación, menores gastos operativos. |

| Aplicaciones Versátiles | Ideal para paneles de ascensor, paneles decorativos de pared, láminas de cocina, trabajos metálicos arquitectónicos, patrones/logos personalizados. Funciona tanto para producción de pequeños lotes como a gran escala. |

| Calidad Reproducible de Nivel Industrial | El control digital asegura resultados 100% reproducibles, ofreciendo a tus clientes acabados mate premium consistentes cada vez. |

💡 Resumen Rápido / Lema para Marketing

“Deja el Arenado Tradicional. Empieza a Ganar. Paneles de Acero Inoxidable Espejado Perfectos, Cada Vez.”

🏭 Aplicaciones de la Máquina Láser de Arenado para Espejos de Acero Inoxidable 1300×2500 mm

Esta máquina es ideal para cualquier negocio que necesite acabados mate premium y reproducibles en acero inoxidable espejado. Sus aplicaciones principales incluyen:

1️⃣ Interiores y Puertas de Ascensores

-

Logra acabados mate uniformes y de alta calidad en paneles grandes de ascensores.

-

Procesa paneles completos sin reposicionamiento, asegurando eficiencia y consistencia.

2️⃣ Paneles Decorativos de Pared

-

Perfecta para revestimientos metálicos arquitectónicos e interiores.

-

Permite texturas o patrones personalizados mientras mantiene una superficie mate impecable.

3️⃣ Láminas de Acero Inoxidable para Cocinas

-

Ideal para backsplash, encimeras y electrodomésticos de cocina.

-

Proporciona un acabado limpio y sin rayaduras, listo para instalación o procesamiento adicional.

4️⃣ Trabajos Metálicos Arquitectónicos e Interiores

-

Adecuada para proyectos comerciales y residenciales que requieran acabados de alta gama.

-

Maneja paneles grandes o formas irregulares, preservando la calidad de la superficie.

5️⃣ Patrones y Logotipos Personalizados

-

Compatible con branding o diseños decorativos sobre superficies de acero inoxidable.

-

El sistema auto-following asegura precisión incluso en paneles curvados o deformados.

6️⃣ Producción de Pequeños Lotes y a Gran Escala

-

Suficientemente flexible para órdenes personalizadas y producción industrial a gran escala.

-

Reduce mano de obra y desperdicio de material, aumentando la eficiencia total.

✅ Resumen

Ya sea que fabriques puertas de ascensores, paneles decorativos de pared, láminas de cocina o trabajos metálicos arquitectónicos personalizados, esta máquina garantiza acabados mate consistentes, sin rayaduras y sin polvo, aumentando la calidad y productividad de tu negocio.

❓ Preguntas Frecuentes – Máquina Láser de Arenado para Espejos de Acero Inoxidable (1300×2500 mm)

Q1: ¿Qué tipos de paneles de acero inoxidable puede procesar esta máquina?

A: Esta máquina está diseñada para paneles de acero inoxidable espejado, incluyendo puertas de ascensor, paneles decorativos de pared, láminas de cocina y trabajos metálicos arquitectónicos. Puede manejar tanto producción de pequeños lotes como producción a gran escala, garantizando acabados mate consistentes.

Q2: ¿Cuál es el tamaño del área de trabajo?

A: El área de trabajo de 1300×2500 mm permite procesar paneles completos sin necesidad de reposicionarlos, reduciendo errores y aumentando la productividad en paneles grandes.

Q3: ¿Qué potencia de láser utiliza la máquina?

A: Utiliza un láser de fibra 100W JPT M7 o Guangzhi, proporcionando energía precisa para acabados mate suaves y sin rayaduras sobre acero inoxidable espejado.

Q4: ¿Cómo funciona el sistema Auto-following?

A: El sistema automático “Engraving-on-the-Go” ajusta automáticamente el enfoque del láser para seguir pequeñas deformaciones o curvaturas en el panel. Esto asegura una profundidad mate uniforme en toda la superficie.

Q5: ¿El proceso es limpio y seguro?

A: Sí. A diferencia del arenado tradicional, esta máquina es sin polvo, no requiere arena ni consumibles, y minimiza la limpieza. La mesa de succión al vacío de nailon mantiene los paneles estables y reduce vibraciones, garantizando seguridad y precisión.

Q6: ¿Puede manejar patrones o logotipos personalizados?

A: Absolutamente. El sistema de control digital permite grabar texturas, patrones o logotipos personalizados con alta precisión en superficies de acero inoxidable espejado.

Q7: ¿Qué tan rápido es el proceso de producción?

A: La gran área de trabajo y el sistema láser automatizado aumentan significativamente el rendimiento, permitiendo procesar paneles completos en una sola pasada. La velocidad de producción es mucho mayor que el arenado tradicional, con resultados consistentes en todo momento.

Q8: ¿Qué mantenimiento requiere?

A: El mantenimiento es mínimo en comparación con el arenado tradicional. No hay arena ni abrasivo que reemplazar, y el láser de fibra es muy duradero. Se recomiendan revisiones periódicas de la mesa de vacío y alineación del láser para un rendimiento óptimo.

Q9: ¿Es adecuada para pedidos pequeños y grandes?

A: Sí. La máquina es versátil, apta para proyectos personalizados de pequeños lotes y producción industrial a gran escala, ofreciendo resultados consistentes y repetibles en todo momento.

Q10: ¿Cuáles son los beneficios clave de usar esta máquina?

A: Los principales beneficios incluyen:

-

Acabado mate impecable y sin rayaduras en acero inoxidable espejado

-

Procesamiento de paneles grandes (1300×2500 mm)

-

Resultados automatizados y repetibles con el sistema “Engraving-on-the-Go”

-

Operación sin polvo, menor mano de obra y reducción de costos

-

Ideal para puertas de ascensor, paneles decorativos, cocinas y trabajos metálicos arquitectónicos

Máquina de grabado láser para vidrio arenado y marcaje láser

Solicite una cotización para una máquina de marcaje láser de fibra

SISMAR LASER cuenta con máquinas láser de fibra y otras soluciones para diversas aplicaciones industriales. Nuestras soluciones pueden funcionar como una mejora para su sistema de marcaje láser existente o como una excelente opción para su primera máquina láser.

Solicite una cotización para una máquina de marcaje láser de fibra de alta calidad que supere sus expectativas. También puede programar una demostración para ver cómo funciona el marcaje láser de fibra.

Bienvenido a SISMAR Laser. Nos complace responder cualquier pregunta sobre nuestras máquinas de marcaje/corte láser de fibra.

1300*2500mm Mirror Laser Sand Blasting Machine

November 24, 2025 /0 Comments/in Products /by linda

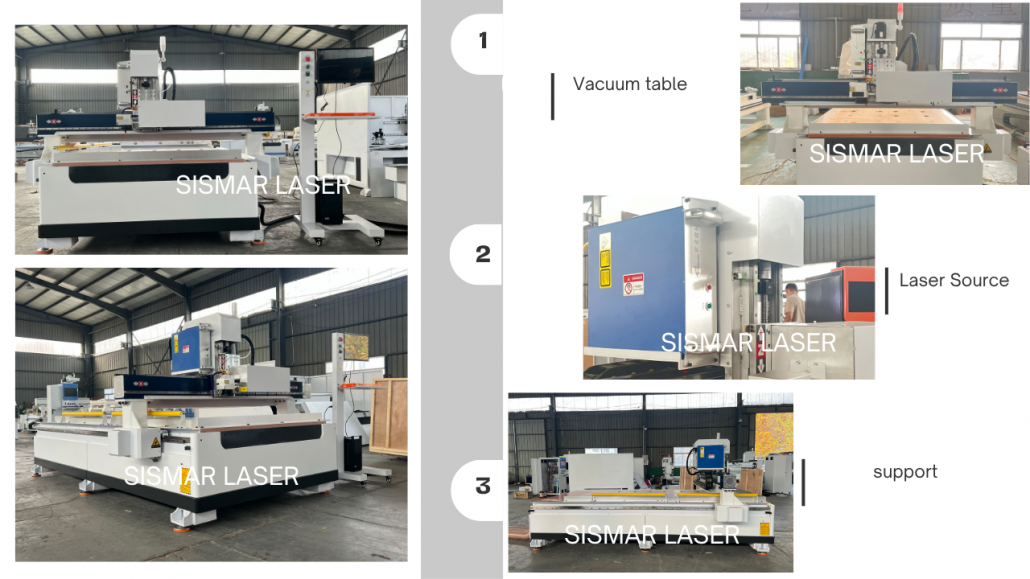

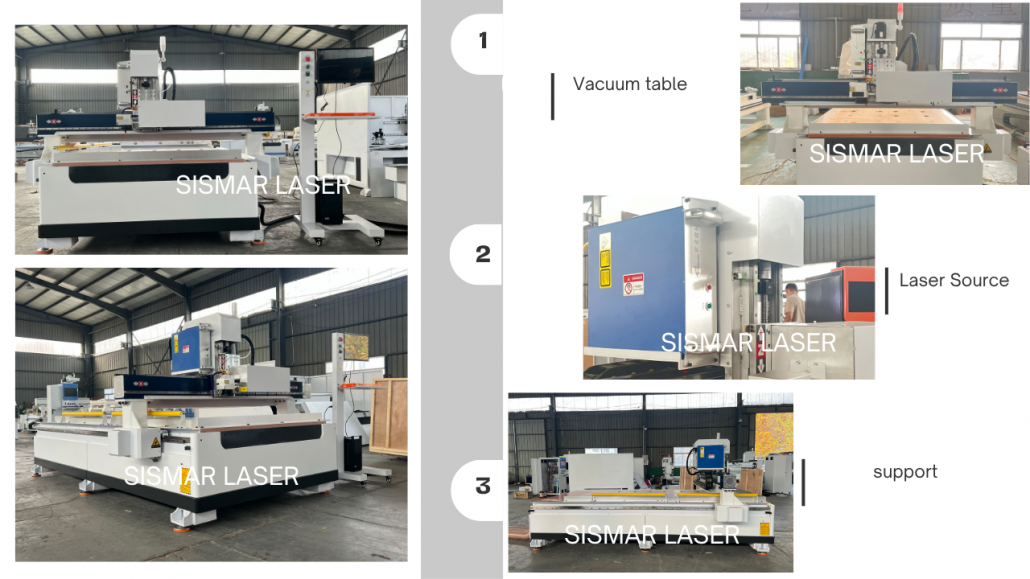

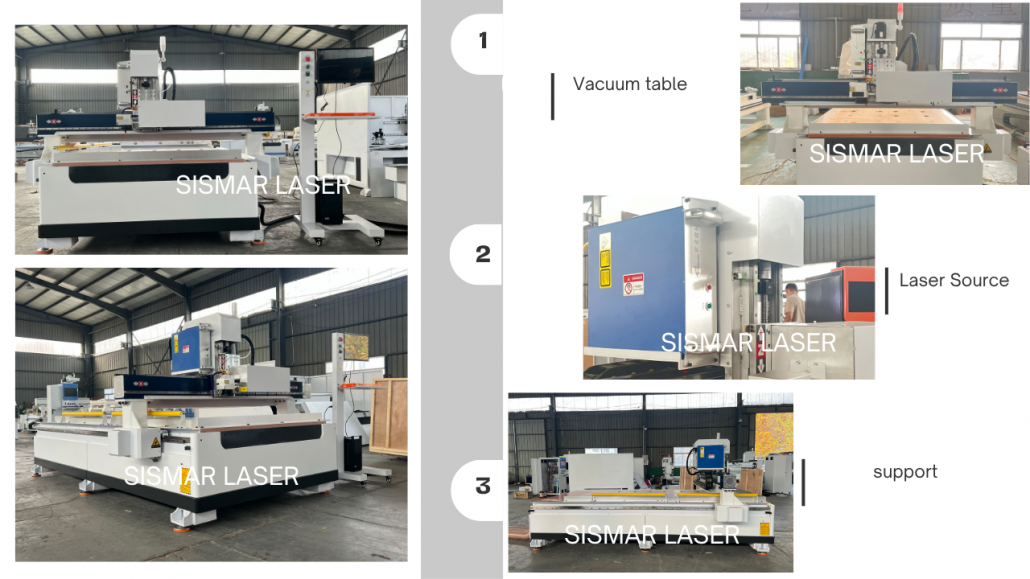

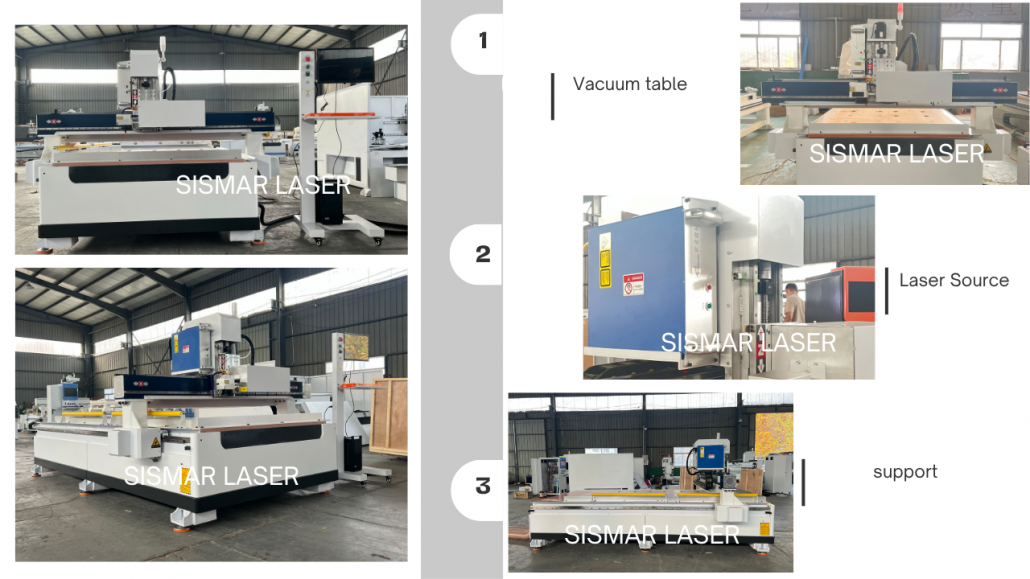

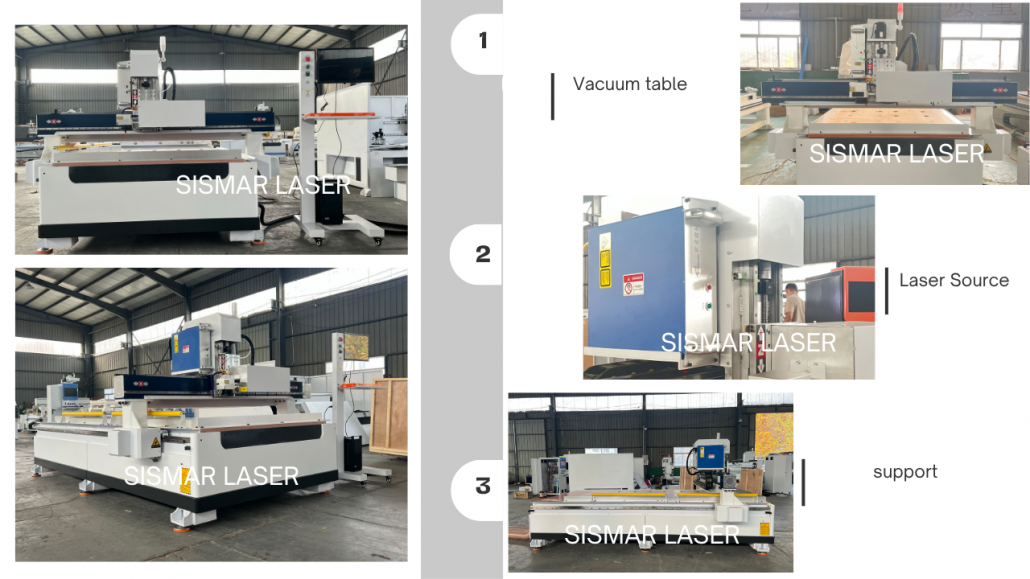

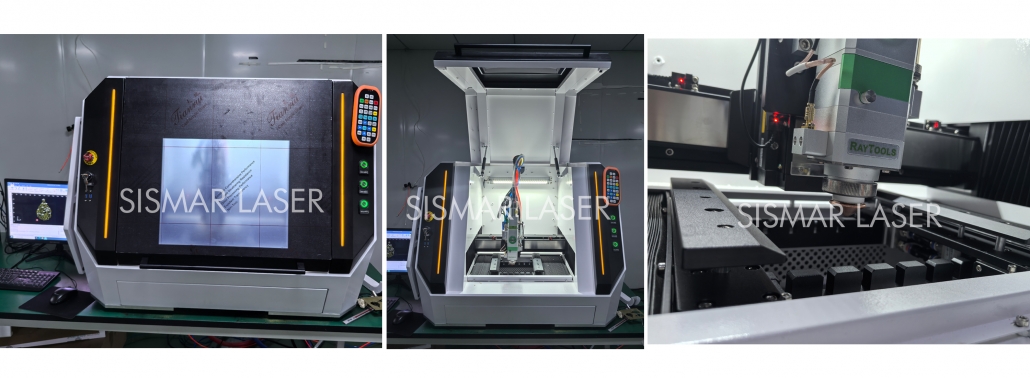

Smart Mirror Laser Sand Blasting & Painting Removal Machine – High-Precision Industrial Solution

1300 × 2500 mm Workspace | Fiber Laser Etching & Mirror Laser Processing System for Smart Mirrors

The Smart Mirror Laser Sand Blasting Machine and Mirror Laser Painting Removal Machine provide industrial-grade precision for smart mirror production.

Featuring a 1300 × 2500 mm working area and an aluminum hollow platform, it supports both smart mirror laser etching and clean paint removal while efficiently managing smoke and debris.

Equipped with a 120W fiber laser and high-speed galvo scanning, this mirror laser processing system ensures consistent matte surfaces, sharp edges, and optimal repeatability.

Ideal for smart mirrors, coated glass, and decorative applications, it streamlines production, reduces labor, and enhances quality—making it perfect for manufacturers and distributors aiming for efficiency and superior results.

Machine Photos of Sand Blasting Mirror Laser Machine

Smart Mirror Laser Sand Blasting & Painting Removal Machine

Industrial-Grade 1300 × 2500 mm Workspace | High-Speed Galvo | Next-Generation Smart Mirror Processing

Smart mirrors are not just reflective surfaces—they are interfaces, lifestyle enhancements, and brand statements.

Their quality is defined by precision, consistency, and clarity.

Our mirror laser sand blasting machine and mirror laser painting removal machine redefine what smart mirror production can achieve.

Designed for manufacturers and distributors alike, this machine delivers:

-

High-speed, high-precision laser processing

-

Clean, uniform matte surfaces

-

Efficient paint removal without damage

-

Integrated debris and smoke management

With 1300 × 2500 mm industrial workspace, it accommodates large mirrors for mass production, while maintaining premium quality standards.

01 / Large-Format Laser System for Smart Mirrors

The smart mirror industry demands larger panels:

bathroom mirrors, fitness mirrors, hotel mirrors, interactive displays, and smart home installations.

Machine Highlights:

-

Full 1300 × 2500 mm working area: process large mirrors in one pass

-

Single-pass finishing: no repositioning, no segmenting, no alignment errors

-

Uniform pattern quality across the entire surface

-

Reduced manual labor: faster production, lower operational cost

Large-format processing ensures consistent smart mirror laser etching results, elevating the perceived product value for end users.

02 / Aluminum Hollow-Structure Platform: Precision & Efficiency

The aluminum hollow platform is engineered for maximum stability and multi-functionality.

-

Optimized for smart mirror sandblasting: smooth, even support protects coatings, heating films, and conductive layers

-

Supports both drilling and laser machining: debris from drilling falls into hollow cavities, avoiding contamination or damage

-

Integrated multi-point smoke extraction: ensures a clean workspace and consistent matte finish

-

Single platform for multiple processes: sandblasting, laser painting removal, and drilling completed without repositioning

This platform ensures production efficiency while maintaining mirror integrity, making it ideal for industrial smart mirror workflows.

03 / 120W Orion / GZ Laser Source: Precision & Reliability

High-power laser output ensures clean, sharp, and repeatable results:

-

Fine, uniform matte surfaces for premium interface quality

-

Efficient paint removal for coating layers without burn or smearing

-

Edge sharpness perfect for UI icons, symbols, logos, and touch zones

-

Continuous high-volume production without thermal distortion

Whether used as a mirror laser sand blasting machine or mirror laser painting removal machine, this laser guarantees optical-grade precision.

04 / Syntec Smart Mirror Processing System: Speed, Accuracy, Consistency

The Syntec control system allows:

-

Complex vector pattern processing at high speed

-

Fine laser modulation for multi-layer coatings

-

Stable performance for long-duration production

-

Consistent results for batch processing

With integrated mirror laser processing system logic, even the most intricate smart mirror layouts—UI icons, interactive panels, and gradient zones—are reproduced with absolute accuracy.

05 / High-Speed Galvo & Quartz F-Theta Lens: Micron-Level Detail

-

High-speed galvo scanning reduces processing time while maintaining precision

-

Quartz F-Theta lens ensures uniform beam quality across the full mirror surface

-

Ideal for intricate smart mirror etching, logo engraving, and UI interface marking

Every detail is accurately represented, achieving a “finished product” effect directly from the machine—no additional processing required.

06 / Industrial Advantages for Smart Mirror Manufacturers

Key Benefits:

-

Premium matte finishes for a superior visual experience

-

High throughput for large-format smart mirrors

-

No abrasive media or post-cleaning required

-

Repeatable precision for mass production

-

Compatible with various mirror coatings and smart mirror layouts

This system transforms smart mirror production into a high-precision, high-efficiency, high-quality workflow.

07 / Distributor Benefits

-

Capitalize on a rapidly expanding smart mirror market

-

Unique mirror laser sand blasting machine technology with high entry barriers

-

Low-maintenance hardware for smooth operations

-

Ideal for OEM brands, mirror factories, smart home integrators

-

Easily demonstrated and sold with clear ROI

This machine is not just equipment—it’s a marketable technology solution.

08 / Technical Specifications

| Parameter | Specification |

|---|---|

| Machine Type | Mirror Laser Sand Blasting & Painting Removal Machine |

| Laser Source | Ouling / Raycus 120W |

| Max Working Area | 1300 × 2500 mm |

| Platform Type | Aluminum Hollow-Structure Platform |

| Processing Speed | Up to 6000 mm/s (Galvo scanning) |

| Laser Wavelength | 1064 nm (Fiber Laser) |

| Software | Syntec Smart Mirror Processing System |

| Supported Materials | Smart mirrors, coated glass, regular glass |

| Cooling System | Water-cooled with thermal protection |

| Dust & Smoke Management | Integrated multi-point extraction & filters |

| Repeatability | ±0.02 mm |

| Power Supply | 380V / 50Hz |

| Dimensions (L×W×H) | 4500 × 2300 × 2300 mm |

| Weight | 1450 kg |

Why Smart Mirror Laser Sanding Is a Game-Changer for Your Glass Business

Still stuck in the past with traditional sandblasting or frosted paint? It’s time to level up. Smart Mirror Laser Sanding is here to revolutionize the way you process glass, offering unbeatable benefits over the old, outdated methods. Here’s why switching to laser sanding will not only save you money but also boost your productivity and make your products stand out.

1. Cut Your Costs: No Consumables, No Problem

- Traditional Sandblasting: You’re constantly replacing abrasives—diamond powder, sand, grit—it’s a never-ending cost.

- Laser Sanding: No consumables. It’s a one-time investment that keeps on giving. You’ll save big on material costs and cut down on waste. Less money spent on replacements means more profit in your pocket.

2. Keep Your Workspace Clean—No Mess, No Dust

- Traditional Methods: Abrasives create a cloud of dust, requiring extra cleanup and protective gear. It’s messy, time-consuming, and can affect your team’s health.

- Laser Sanding: No dust, no debris. It’s contactless and clean—just a focused beam of light that gets the job done. You’re working in a cleaner, safer environment, and your team will thank you.

3. Precision Like Never Before: Perfect Every Time

- Traditional Sandblasting: Achieving the right texture? Good luck. It’s inconsistent, and you’ll often end up with uneven results.

- Laser Sanding: Laser accuracy means you can create intricate patterns, complex textures, and stunning effects on glass—all with flawless precision. No mistakes, no rework, just perfection.

4. Durable Results That Last

- Frosted Paint: Looks good at first, but it wears off over time. You’ll need to touch it up, and your customers won’t be happy when it starts to fade.

- Laser Sanding: The finish created by the laser is permanent. It’s resistant to wear, won’t chip, and stays looking fresh for years. Your customers will love the long-lasting quality.

5. Save Time, Save Money: Automated for Maximum Efficiency

- Traditional Sandblasting: Manual labor, constant adjustments, and slow processing times. It’s inefficient and costly.

- Laser Sanding: With automation in the mix, you’re getting faster production times, reduced labor costs, and better output. More work done in less time, without sacrificing quality.

6. Versatility Across the Board

- Traditional Sandblasting: Can’t handle all types of glass, and the results can be inconsistent depending on the material.

- Laser Sanding: Works perfectly on all types of glass, from smart mirrors to decorative glass, art pieces, and household items. Plus, it’s flexible enough to handle any design challenge you throw at it.

The Takeaway: Switch to Smart Mirror Laser Sanding

If you’re tired of dealing with messy, inefficient, and outdated methods, it’s time to embrace the future with Smart Mirror Laser Sanding. It’s faster, cleaner, more precise, and delivers results that last. By cutting your costs, improving production, and offering better-quality finishes, laser sanding will take your business to the next level.

So, what are you waiting for? Say goodbye to the old way of doing things and embrace the future of glass processing today.

Mirror Laser Sand Blasting Machine Applications

The Mirror Laser Sand Blasting Machine is ideal for a variety of industries. Here’s how it can be used:

1. Smart Mirror Manufacturing

Use the mirror laser sand blasting machine to create frosted effects on smart mirrors. It allows you to add custom patterns and designs to mirrors without the need for films or coatings. This is perfect for high-precision work in smart mirror production.

2. Architectural Glass Processing

This machine is perfect for creating frosted glass and decorative effects on architectural glass. You can use it for windows, partitions, and building facades, adding unique designs to enhance the aesthetics of any structure.

3. Customized Glass Art

For glass artists, the mirror laser sand blasting machine is a game changer. It allows for detailed, precise engraving on glass surfaces, creating personalized and intricate designs on glass art pieces.

4. Automotive Glass Customization

The laser sand blasting machine is great for automotive glass customization. Add branding, logos, or unique designs to car windows and other glass parts. This technology allows you to achieve custom engravings and patterns with ease.

5. Signage and Branding

With the mirror laser sand blasting machine, you can create glass signage and awards by etching logos, names, and designs. It’s perfect for companies looking to make custom glass signs or promotional materials.

6. Mirror Restoration and Repair

This machine is also useful for restoring old mirrors. It can remove scratches, stains, or old coatings to bring mirrors back to life, leaving them with a smooth, fresh finish.

7. Household Glass Items

From glassware to home décor, the mirror laser sand blasting machine allows you to engrave custom designs on various glass products. It’s great for creating personalized gifts or adding unique touches to household items.

Why Choose the Mirror Laser Sand Blasting Machine?

- Precision: Achieve exact designs with high accuracy.

- Eco-friendly: No dust, no chemicals—just clean and efficient processing.

- Durability: The designs last longer and stay intact, unlike painted finishes that may fade or peel.

Frequently Asked Questions (FAQ)

1️⃣ What is a Mirror Laser Sand Blasting Machine used for?

The Mirror Laser Sand Blasting Machine is primarily used for creating mirror finishes, sandblasting surfaces, and removing paint from metal, glass, and other materials. It can create smooth, glossy finishes on surfaces and remove coatings like paint, rust, and oxide layers.

2️⃣ Can this machine remove paint from all types of surfaces?

Yes, the Mirror Laser Sand Blasting Machine is highly effective for removing paint from various surfaces, including metal, glass, plastic, and stone. It’s ideal for paint stripping, surface cleaning, and restoration of materials without damaging the underlying substrate.

3️⃣ What types of materials can be treated with the Mirror Laser Sand Blasting Machine?

This machine is suitable for a wide range of materials including metal, glass, plastic, stone, and ceramics. It’s perfect for industries like automotive, construction, art restoration, and metalworking, where the need for surface treatment and paint removal is critical.

4️⃣ How does the machine create a mirror-like finish?

The Mirror Laser Sand Blasting Machine uses advanced laser technology to sandblast surfaces, creating a reflective, smooth, and glossy finish. By adjusting the laser settings, the machine can create different levels of gloss or matte finishes depending on your project requirements.

5️⃣ Does the machine leave any residue or damage the surface?

No, the Mirror Laser Sand Blasting Machine is designed to be gentle yet effective. It uses laser-based precision sandblasting, meaning it won’t cause damage or leave residue on the material. The painting removal process is also non-abrasive, ensuring the surface stays intact.

6️⃣ How effective is the machine at paint removal?

The laser sandblasting machine provides an extremely efficient way to remove paint without damaging the material underneath. It’s highly effective for removing layers of paint, rust, and oxidation from materials such as automobile parts, metal structures, industrial equipment, and machinery.

7️⃣ Is the machine suitable for industrial use?

Yes, the Mirror Laser Sand Blasting Machine is designed to meet industrial requirements. It’s capable of handling large-scale projects with high efficiency, making it ideal for use in industries such as automotive, construction, manufacturing, and art restoration.

8️⃣ How does the paint removal process work?

The paint removal process is done through laser ablation, where the laser beam is used to break down the paint or coating. It doesn’t use chemicals or abrasives, making it eco-friendly and safe for use in various environments.

9️⃣ Is the machine easy to operate?

Yes, the Mirror Laser Sand Blasting Machine is designed to be user-friendly. It typically comes with an intuitive interface that allows operators to adjust settings such as laser power, speed, and frequency, making it easy to handle even for beginners.

🔟 What is the maintenance required for this machine?

The machine requires minimal maintenance. Regular cleaning of the lens and checking of the laser system are essential to ensure optimal performance. It’s important to ensure that the machine is running in a well-ventilated area to maintain its efficiency.

1️⃣1️⃣ What is the lifespan of the machine?

The Mirror Laser Sand Blasting Machine has a long lifespan if properly maintained. The laser system is designed to withstand continuous use, and with minimal upkeep, you can expect many years of reliable performance.

1️⃣2️⃣ How much power does the machine consume?

The power consumption of the machine will vary based on the model and the material being treated. However, laser-based technology is generally energy-efficient compared to traditional abrasive methods, helping to reduce operational costs.

1️⃣3️⃣ Can the machine work on intricate designs or detailed areas?

Yes, the Mirror Laser Sand Blasting Machine can handle intricate and detailed designs with precision. It allows for fine control in both painting removal and sandblasting, making it suitable for applications that require high levels of detail.

1️⃣4️⃣ Is it eco-friendly?

Yes, the Mirror Laser Sand Blasting Machine is considered eco-friendly since it eliminates the need for harsh chemicals and abrasives used in traditional sandblasting and paint removal methods. It also produces less waste, contributing to a cleaner and more sustainable environment.

Laser Marking Sandblasted Glass Laser Etching Machine

Request a Quote for a Fiber Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

Stainless Steel Mirror Laser Sand Blasting Machine (1300×2500mm)

November 18, 2025 /0 Comments/in Products /by linda

Stainless Steel Mirror Laser Sand Blasting Machine (1300×2500mm)

Make Mirror Stainless Steel Panels Perfect, Every Time.

Stainless Steel Mirror Laser Sand Blasting Machine (1300×2500mm)

Upgrade your stainless steel finishing process with our 1300×2500mm Stainless Steel Mirror Laser Sand Blasting Machine. Designed for elevator panels, decorative wall panels, kitchen sheets, and architectural metalwork, this machine delivers flawless, scratch-free matte finishes every time.

Equipped with a 100W JPT M7 / Guangzhi fiber laser, a nylon vacuum suction table, and the Auto-following “Engraving-on-the-Go” system, it automatically adjusts for warped or curved panels, ensuring perfect uniformity.

Say goodbye to sand, dust, and messy cleanup, and enjoy faster production, lower labor costs, and repeatable high-quality results—ideal for both small batches and large-scale industrial projects.

Machine Photos of Sand Blasting Mirror Laser Machine

Stop Struggling With Uneven Matte Finishes

If you’ve ever worked with mirror stainless steel, you know the frustration:

One panel looks great, the next has streaks

Traditional sandblasting creates dust, mess, and wasted material

Big panels are a pain to handle and finish evenly

This 1300×2500mm laser sand blasting machine was designed for professionals who need perfect matte finishes on mirror stainless steel panels, elevator doors, kitchen sheets, and decorative panels, every single time.

Why This Machine Matters

Traditional methods are slow, messy, and inconsistent. Our laser sandblasting solution changes the game:

-

Large 1300×2500 mm work area → process full-size panels in one go, no repositioning needed.

-

Nylon vacuum suction table → keeps sheets stable, protects the surface, ensures uniform matte finishing.

-

100W JPT M7 / Guangzhi laser → consistent energy for smooth, premium matte results.

-

Auto-following “Engraving-on-the-Go” system → follows slight bends or warps, keeping the finish perfectly even.

-

No sand, no dust, no cleanup → safer, cleaner, and cheaper than traditional sandblasting.

Think of it as precision, speed, and reliability all in one machine.

How It Works

-

Place your mirror stainless steel panel on the nylon vacuum table.

-

The laser follows the panel automatically, adjusting for curves or warps.

-

A fine, uniform matte finish is created, like traditional sandblasting—but faster, cleaner, and completely digital.

-

Panels are ready to install or deliver. No dust. No scratches. No guesswork.

Perfect For These Applications

-

Elevator doors & panels

-

Decorative wall panels

-

Kitchen stainless steel sheets

-

Architectural and interior metalwork

-

Custom patterns or logos

-

Both small batch and mass production

If your business needs repeatable, premium matte finishes on mirror stainless steel, this machine will save time, reduce waste, and make your work look professional—every time.

Technical Specs That Deliver Results

| Feature | Why It Matters |

|---|---|

| Working area: 1300×2500 mm | Handle large panels without repositioning |

| Laser: JPT M7 / Guangzhi 100W | High power, smooth, consistent matte finish |

| Table: Nylon vacuum suction | Protects surface, prevents vibration |

| Auto-following system | Auto-following “Engraving-on-the-Go” system ensures perfect matte on warped panels |

| Process | Dust-free, no consumables, no mess |

Why Choose This Laser Sand Blasting Machine?

-

Perfect matte, every panel – no streaks, no scratches

-

Handles large sheets – elevator panels, wall panels, decorative sheets

-

Cleaner, safer, cheaper – no sand, no dust, no cleanup

-

Faster production – automated, precise, repeatable

-

Digital control – consistent results, less human error

Stop wasting time with traditional methods. Upgrade to a Stainless Steel Mirror Laser Sand Blasting Machine and make your panels look flawless—every time.

The Stainless Steel Mirror Laser Sand Blasting Machine is perfect for companies looking for laser sandblasting machines for mirror stainless steel. Its 1300×2500 laser sand blasting machine workspace, nylon vacuum table, and 100W industrial laser ensure consistent, high-quality results. Whether you’re finishing elevator doors, decorative panels, or kitchen sheets, this stainless steel matte laser machine saves time, reduces waste, and delivers professional-grade matte finishes—every time.

🚀 Key Advantages of the 1300×2500 Stainless Steel Mirror Laser Sand Blasting Machine

| Advantage | Why It Matters / Benefit |

|---|---|

| Flawless Mirror Finish Every Time | Auto-following “Engraving-on-the-Go” system compensates for warped panels, delivering uniform matte finishes without streaks or shallow spots. |

| Large 1300×2500 mm Working Area | Process full-size elevator doors, decorative panels, or kitchen sheets in one go—no repositioning, fewer errors, higher throughput. |

| Scratch-Free and Precise | 100W JPT M7 / Guangzhi fiber laser atomizes the surface while protecting the reflective base layer, ensuring premium-quality results. |

| Stable, Vibration-Free Processing | Nylon vacuum suction table holds panels firmly, preventing movement and guaranteeing perfect pattern fidelity. |

| Dust-Free and Eco-Friendly | No sand, no grit, no cleanup. Cleaner environment, lower labor costs, safer operation. |

| High Efficiency and Cost Savings | Automated processing reduces manual labor and production time. No consumables, no ventilation costs, lower operational expenses. |

| Versatile Applications | Ideal for elevator panels, decorative wall panels, kitchen sheets, architectural metalwork, custom patterns/logos. Works for both small-batch and large-scale production. |

| Repeatable, Industrial-Grade Quality | Digital control ensures 100% reproducible results, giving your clients consistent premium matte finishes every time. |

Quick Summary / Tagline for Marketing

“Stop Sandblasting. Start Profiting. Flawless Mirror Stainless Steel Panels, Every Time.”

Applications of the 1300×2500 Stainless Steel Mirror Laser Sand Blasting Machine

This machine is ideal for any business that requires premium, repeatable matte finishes on mirror stainless steel. Key applications include:

1. Elevator Interiors & Doors

-

Achieve uniform, high-quality matte finishes for large elevator panels.

-

Handles full-size panels without repositioning, ensuring efficiency and consistency.

2. Decorative Wall Panels

-

Perfect for architectural and interior metal cladding.

-

Enables custom textures or patterns while maintaining a flawless matte surface.

3. Kitchen Stainless Steel Sheets

-

Ideal for kitchen backsplash, countertops, and appliances.

-

Provides a clean, scratch-free finish, ready for installation or further processing.

4. Architectural & Interior Metalwork

-

Suitable for commercial and residential projects requiring high-end finishes.

-

Handles large panels or irregular shapes, preserving surface quality.

5. Custom Patterns and Logos

-

Supports branding or decorative designs on stainless steel surfaces.

-

Auto-following system ensures precision on warped or curved panels.

6. Small-Batch & Mass Production

-

Flexible enough for custom orders and large-scale industrial production.

-

Reduces labor and material waste, increasing overall efficiency.

Summary:

Whether you manufacture elevator doors, decorative wall panels, kitchen sheets, or custom architectural metalwork, this machine ensures consistent, scratch-free matte finishes with zero dust, boosting quality and productivity.

FAQ – Stainless Steel Mirror Laser Sand Blasting Machine (1300×2500mm)

Q1: What types of stainless steel panels can this machine process?

A: This machine is designed for mirror stainless steel panels, including elevator doors, decorative wall panels, kitchen sheets, and architectural metalwork. It can handle both small-batch and large-scale production with consistent matte finishes.

Q2: How large is the working area?

A: The 1300×2500 mm working area allows full-panel processing without repositioning, reducing errors and increasing throughput for large panels.

Q3: What laser power does the machine use?

A: It uses a 100W JPT M7 or Guangzhi fiber laser, providing precise energy for smooth, scratch-free matte finishes on mirror stainless steel.

Q4: How does the Auto-following system work?

A: The Auto-following “Engraving-on-the-Go” system automatically adjusts the laser focus to follow slight warps or bends in the panel. This ensures uniform matte depth across the entire surface.

Q5: Is the process clean and safe?

A: Yes. Unlike traditional sandblasting, this machine is dust-free, requires no sand or consumables, and minimizes cleanup. The nylon vacuum suction table keeps panels stable and reduces vibration, ensuring safety and precision.

Q6: Can it handle custom patterns or logos?

A: Absolutely. The digital control system allows you to engrave custom textures, patterns, or logos with high precision on mirror stainless steel surfaces.

Q7: How fast is the production process?

A: The large working area and automated laser system significantly increase throughput, allowing full panels to be processed in a single pass. Production speed is much faster than traditional sandblasting, with consistent results every time.

Q8: What maintenance is required?

A: Maintenance is minimal compared to traditional sandblasting. There is no sand or grit to replace, and the fiber laser is highly durable. Regular checks of the vacuum table and laser alignment are recommended for optimal performance.

Q9: Is it suitable for both small and large orders?

A: Yes. The machine is versatile for small-batch custom projects and large-scale industrial production, providing consistent, repeatable results every time.

Q10: What are the key benefits of using this machine?

A: Key benefits include:

-

Flawless, scratch-free matte finish on mirror stainless steel

-

Large panel processing (1300×2500 mm)

-

Automated, repeatable results with “Engraving-on-the-Go” system

-

Dust-free operation, reduced labor, and lower costs

-

Perfect for elevators, decorative panels, kitchens, and architectural metalwork

Laser Marking Sandblasted Glass Laser Etching Machine

Request a Quote for a Fiber Laser Marking Machine