Author Archive for: linda

About linda

This author has yet to write their bio.Meanwhile lets just say that we are proud linda contributed a whooping 427 entries.

Entries by linda

UV laser marking machine

January 29, 2025 /0 Comments/in Blog /by lindaUV Laser Marking Machine – Why It Outshines Fiber and CO2 Lasers

January 29, 2025 /0 Comments/in Solution of Common Problems /by lindaAdvantage and Application

January 29, 2025 /0 Comments/in Solution of Common Problems /by lindaSmallest Fiber Laser Cutting Machine for Jewelry – 800W, 1000W, 1500W, 200x300mm

January 8, 2025 /0 Comments/in Products /by linda

Smallest Jewelry Laser Cutting Machine 1500W – For 925 Silver & 18K Gold

925 Silver & 18K Gold Laser Cutting Machine

Compact Size · High Precision · Big Performance

The Smallest Jewelry Laser Cutting Machine is specially designed for jewelry manufacturing and other high-precision metal cutting industries.

With a 200×300mm working area, up to 1500W fiber laser power, and ±0.01mm cutting accuracy, it delivers outstanding performance in a compact footprint. Perfect for processing 925 silver, 18K gold, brass (1mm), and other precious metals, this silver gold necklace laser cutting machine ensures flawless, burr-free results every time.

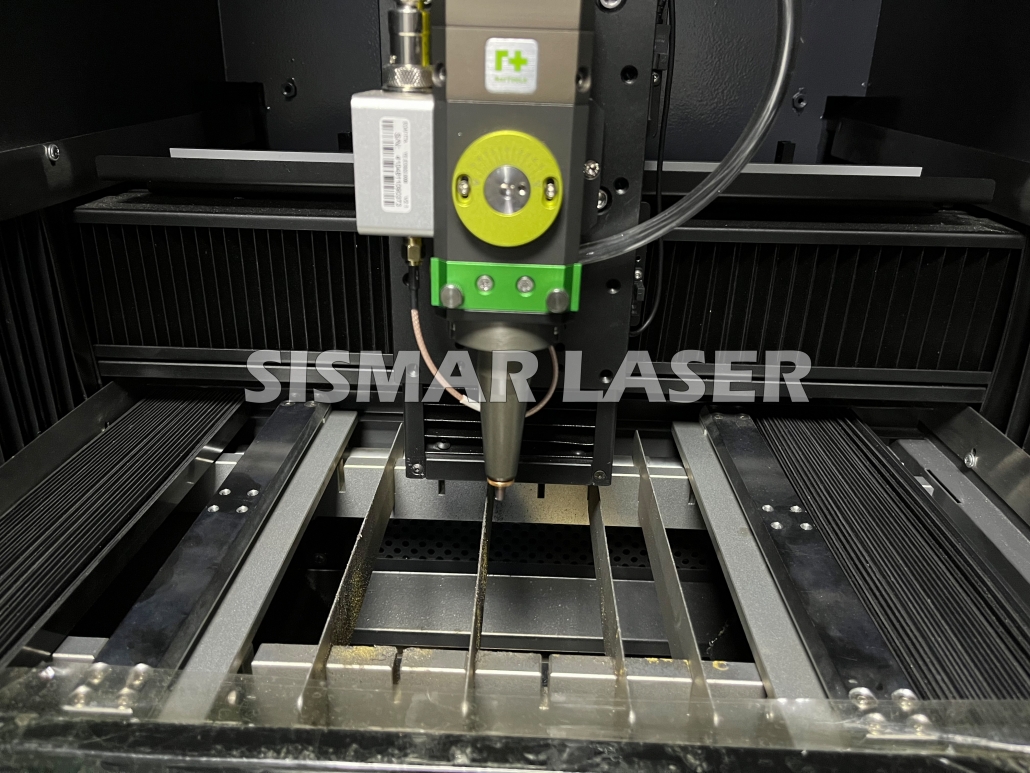

Photos of 200*300mm Fiber Laser Cutting Machine

Product Overview

In the jewelry industry, where precision, efficiency, and aesthetics are key, this 1500W fiber laser cutting machine stands out. Whether cutting intricate hollow designs or customizing high-end necklaces, rings, and pendants, it delivers perfect detail with speed and stability.

Its small footprint makes it ideal for small workshops, jewelry studios, and businesses with limited space — without compromising on cutting power or quality.

Key Features & Benefits

1. Compact Design & Flexible Installation

-

Small Footprint: 200×300mm working area, ideal for jewelry shops and small production facilities.

-

Air-Cooled Laser Source: Eliminates water-cooling systems, saving space and simplifying setup.

-

Easy Integration: Fits into existing production lines without major layout changes.

2. Powerful Cutting & High Precision

-

Laser Power Options: 800W, 1000W, and 1500W fiber laser cutting machine.

-

Material Range: Perfect for 925 silver, 18K gold, 1mm brass, stainless steel, and other precious metals.

-

Ultra-High Accuracy: ±0.01mm precision for intricate jewelry designs.

-

High Cutting Speed: Optimized for mass production.

3. Intelligent Operation & Material Efficiency

-

Auto-Focus Technology: Adjusts automatically for different thicknesses.

-

Intelligent Nesting System: Maximizes material usage and reduces waste.

4. Smooth Cutting Without Post-Processing

-

Burr-Free Edges: No burn marks or polishing required.

-

Consistent Product Aesthetics: Ensures premium appearance for jewelry items.

Industry Pain Points & Solutions

-

Pain Point: Traditional cutting methods often cause burnt edges and burrs.

Solution: High-precision laser beam with auto-focus technology ensures smooth, burr-free edges with no secondary processing. -

Pain Point: Water-cooled systems take up large space and require complex maintenance.

Solution: Air-cooled design eliminates the need for a chiller, saves space, and simplifies upkeep. -

Pain Point: High material wastage rates increase production costs.

Solution: Intelligent nesting system maximizes material utilization and reduces waste.

Applications

-

Jewelry Manufacturing: Cutting 925 silver, 18K gold, and other precious metals for necklaces, pendants, rings, and bracelets.

-

Precision Metal Processing: Ideal for micro-components, prototypes, and customized designs.

-

Small Workshops & Studios: Compact design fits limited workspace without compromising performance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Working Area | 200×300mm |

| Laser Power | 500W / 800W / 1000W / 1500W |

| Positioning Accuracy | ±0.01mm |

| Cutting Thickness | 0.1mm – 2mm |

| Machine Size | 950×820×780mm |

| Machine Weight | 220kg |

| Assist Gas | Nitrogen, Air |

| Control System | Intelligent Nesting System |

Advantages of the Smallest Jewelry Laser Cutting Machine (200×300mm, up to 1500W)

-

Ultra-Compact Design with Minimal Footprint

-

Smallest silver gold necklace laser cutting machine with a 200×300mm working area.

-

Perfect for jewelry shops, small workshops, and production facilities with limited space.

-

Flexible installation — integrates easily into existing production lines without major changes.

-

-

Wide Application Range for Precious Metals

-

Compatible with 925 silver laser cutting, 18K gold laser cutting, and other precious metals.

-

Ideal for creating pendants, rings, bracelets, necklaces, and intricate hollow designs.

-

Also suitable for 1mm brass laser cutting, micro-component manufacturing, and prototyping.

-

-

High Efficiency & Cost Savings

-

Powerful 1500W fiber laser cutting machine delivers high-speed, high-precision results.

-

Narrow cutting seams reduce material waste, especially for expensive metals like gold and silver.

-

Optimized for mass production, reducing processing time and labor costs.

-

-

User-Friendly Operation & Low Maintenance

-

Intuitive control system for easy operation, even for beginners.

-

Air-cooled design eliminates the need for complex water-cooling systems.

-

Durable build ensures long-term reliability with minimal downtime.

-

FAQ – Smallest Jewelry Laser Cutting Machine (200×300mm, up to 1500W)

Q1: What materials can this jewelry laser cutting machine process?

A1: This 1500W fiber laser cutting machine is designed for 925 silver, 18K gold, and other precious metals. It can also process stainless steel, titanium, and 1mm brass with excellent precision.

Q2: What is the maximum cutting thickness?

A2: It can cut materials from 0.1mm to 2mm depending on the metal type and laser power setting.

Q3: How accurate is the cutting?

A3: The machine offers ±0.01mm cutting accuracy, making it ideal for intricate jewelry designs, micro-components, and customized pieces.

Q4: Do I need a water cooling system?

A4: No. This jewelry laser cutting machine uses an air-cooled laser source, which saves space, reduces maintenance, and simplifies installation.

Q5: Is it suitable for small workshops or studios?

A5: Yes. With a 200×300mm working area and compact size, it is perfect for jewelry studios, small production facilities, and stores with limited space.

Q6: Can I cut both silver and gold on the same machine?

A6: Yes. The smallest silver gold necklace laser cutting machine can switch between 925 silver laser cutting and 18K gold laser cutting without needing major adjustments.

Q7: What is the lifespan of the laser source?

A7: The fiber laser source typically lasts over 100,000 hours, offering long-term reliability and stable performance.

Q8: How easy is it to operate for beginners?

A8: The machine features a user-friendly control interface and auto-focus technology, making it easy to operate even for users with no prior laser cutting experience.

Q9: Does it require much maintenance?

A9: Maintenance is minimal. The air-cooled system and durable components reduce downtime and servicing needs.

Q10: Can I use it for mass production?

A10: Absolutely. The high cutting speed and intelligent nesting system make it ideal for bulk jewelry manufacturing while maintaining consistent quality.

More 200*300mm fiber laser cutting machine videos

Request a Quote for a Fiber laser Cutting Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing Fiber laser cutting system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser cutting machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking cutting works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

Training Video Mini Cover Fiber Laser engraving cutting Machine

December 26, 2024 /0 Comments/in Software Opeartion, Video /by linda

Training Video of Mini Cover Laser engraving cutting machine

how to connect mini cover fiber laser

How to mark ring inner and outter

How to install Jewelry rotary device

How to install driver on laptop

How to design jewelry name using AI

How to laser marking photo

How to opearte ezcad

How to cut jewelry necklace

Training video of Mini fiber laser engraving cutting machine

December 26, 2024 /0 Comments/in Software Opeartion, Video /by linda

Training Video of Mini Laser engraving cutting machine

how to connect mini fiber laser

How to mark ring inner and outter

How to install Jewelry rotary device

How to install driver on laptop

How to design jewelry name using AI

How to laser marking photo

How to opearte ezcad

How to cut jewelry necklace

Training video of 6050 fiber laser cutting machine

December 26, 2024 /0 Comments/in Software Opeartion, Video /by linda

Training video of 6050 fiber laser cutting machine

How to connect 6050 fiber laser cutting machine

Traning video of Raytools Laser cutting software

Training video of flying laser marking machine

December 26, 2024 /0 Comments/in Software Opeartion, Video /by linda

Training video of flying laser marking machine for PVC pipe

Operation video of flying laser marking machine

J2000 Flying laser system

Training Video of SUP23T handheld fiber laser welding machine

December 26, 2024 /0 Comments/in Software Opeartion, Video /by linda

Training Video of Handheld Fiber Laser welding/Cleaning Machine

SUP23T Laser Welding system

FWH30 Laser Welding system

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am

- EZCAD common errorMarch 18, 2025 - 2:09 am