Author Archive for: linda

About linda

This author has yet to write their bio.Meanwhile lets just say that we are proud linda contributed a whooping 427 entries.

Entries by linda

Laser Glass Drilling Industry

December 28, 2023 /0 Comments/in Solution of Common Problems /by linda

Laser applications in the glass industry

Laser applications in the glass industry have become increasingly prevalent due to the precision, versatility, and efficiency offered by laser technology.

Here are some common laser applications in the glass industry:

1.Glass Drilling:

- Hole Drilling: Lasers can be employed to drill precise holes in glass, allowing for the creation of decorative patterns or facilitating mounting.

2.Glass Cutting:

Precision Cutting: Lasers can cut glass with high precision, enabling the creation of intricate shapes and designs.

Thin Glass Cutting: Laser technology is suitable for cutting thin glass sheets used in electronic devices and displays.

3.Glass Engraving and Etching/Sand blasting:

Surface Engraving: Lasers can engrave intricate patterns and designs on the surface of glass for decorative purposes.

4.Glass Marking and Labeling:

Barcoding and Serialization: Lasers are used to mark glass products with barcodes, serial numbers, and other identification information.

Logo and Text Marking: Lasers can apply logos, brand names, and other text directly onto glass surfaces.

In this Artical,we focus on Glass Laser Drilling.

Glass drilling has traditionally been a delicate and intricate process, often requiring specialized tools and skilled artisans. The advent of Glass Drilling Laser Machines has revolutionized this practice, offering unparalleled precision in creating holes of various sizes and shapes. The laser’s focused energy allows for pinpoint accuracy, enabling the creation of intricate designs and patterns on glass surfaces.

Applications in the Glass Industry:

Decorative Design: Glass drilling laser machines empower artisans and manufacturers to incorporate intricate designs and patterns directly onto glass surfaces. From artistic installations to functional designs, the possibilities are virtually limitless.

Hole Drilling: Whether for mounting hardware, creating drainage holes, or facilitating wiring passages, these machines provide a precise and efficient solution. The ability to drill holes in various glass thicknesses expands the range of applications across industries.

Microstructuring: Glass drilling laser machines can be employed for microstructuring glass surfaces, enabling the creation of small, intricate features. This capability is invaluable in applications such as microfluidics and the manufacturing of precision instruments.

Repair and Restoration: In the realm of glass repair, these machines offer a delicate yet effective method for addressing cracks and chips. By carefully applying laser energy to the affected area, artisans can restore the structural integrity of the glass.

Benefits of Glass Drilling Laser Machines:

High Precision: The laser’s focused beam ensures unparalleled precision in drilling, reducing the margin of error and enhancing the overall quality of the finished product.

Versatility: Glass drilling laser machines are versatile tools, capable of handling various glass thicknesses and accommodating diverse design requirements. This adaptability makes them an invaluable asset across different industries.

Time Efficiency: Compared to traditional drilling methods, laser drilling is often faster and more efficient. This increased speed contributes to enhanced productivity in manufacturing processes.

Reduced Material Waste: The precision of laser drilling minimizes the likelihood of material wastage, making it a more sustainable option for glass processing.

Conclusion:

As the glass industry continues to embrace technological advancements, the Glass Drilling Laser Machine stands out as a game-changer. Its ability to achieve precision, versatility, and efficiency opens up new possibilities for designers, manufacturers, and artisans. From creating intricate patterns to facilitating functional features, this technology has undoubtedly etched its mark on the future of glass processing.

Glass Laser drilling/Marking/Sand Blasting video

Explanation of Glass Laser Drilling

Mini Laser Drilling Glass Machine

Large Size Laser Drilling Glass Machine

Custom Made Glass Laser Drilling

Glass Laser Sand Blasting Machine

Custom Made Laser Drilling Glass Machine

Laser Marking Zipper/Slider by CCD visual Position Laser Marking Machine

October 27, 2023 /0 Comments/in Solution /by linda

Laser marking Zipper/Slider by CCD Visual Position Laser Marking Machine

During the traditional laser marking process, the processed parts must be in a fixed position and not be shaken.

CCD visual position laser marking machine can automatically identify product features for laser marking to achieve rapid positioning, and even small objects can also be marked with high precision, without the need to use fixtures, reducing With manual participation, work efficiency is improved.

CCD Laser marking zipper/slider videos show

Glass Drilling Laser Machine

September 8, 2023 /0 Comments/in Products /by linda

Glass laser drilling machine

Glass Drilling And Cutting Machine - Laser Style!

Unlock Precision with the Glass Laser Drilling Machine

Tired of traditional drilling methods that risk damaging your glass? The Glass Laser Drilling Machine takes your drilling game to the next level—no mess, no stress. With cutting-edge laser technology, it delivers precise, clean holes every time, whether you’re working with thin sheets or thicker glass.

What’s in it for you?

- Unmatched Precision: Drill micro-holes with pinpoint accuracy.

- Speed and Efficiency: Get the job done faster, with minimal waste.

- Non-Contact Drilling: No more cracks or breakage. It’s gentle on your glass.

- Versatile: Perfect for automotive glass, electronic displays, and decorative projects.

Ready to elevate your production? The Glass Laser Drilling Machine makes your glass drilling easy, precise, and incredibly efficient.

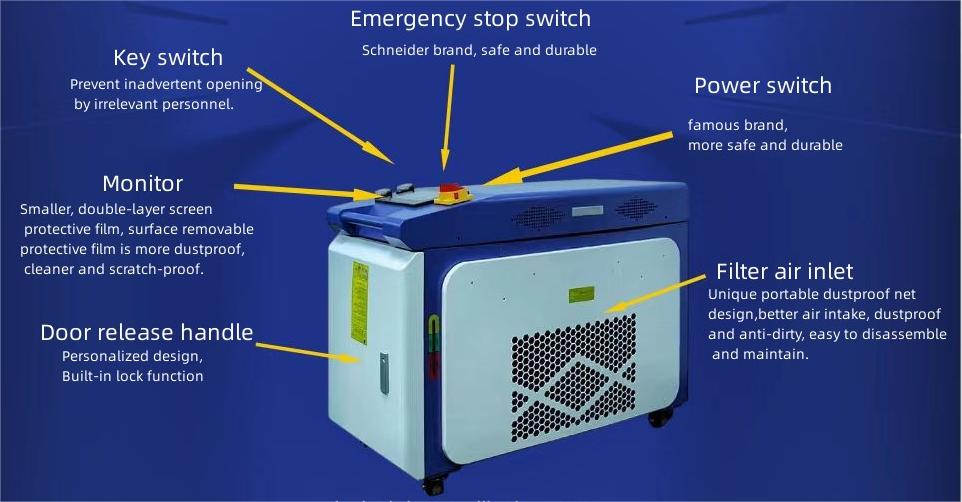

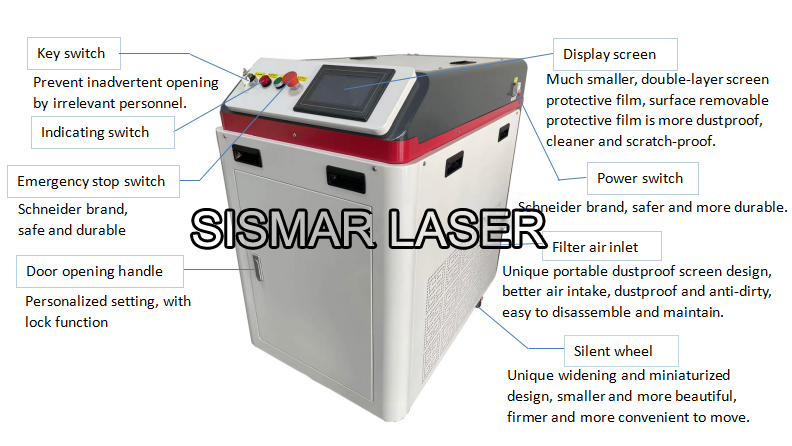

Glass Drilling Laser Machine

Glass Drilling Laser Machine Detail info

Glass Laser Drilling Machine – Precision, Efficiency, and Innovation in Every Hole

Are you tired of traditional drilling methods that cause cracks and imperfections in your glass? The Glass Laser Drilling Machine uses advanced laser technology to offer an innovative drilling solution—no mechanical force, no risk of damage. It’s the future of glass drilling, ensuring precise results every time.

How It Works: The machine utilizes a laser beam that focuses on the surface of the glass, creating clean, micro-sized holes with extreme precision. Since it’s a non-contact process, there’s no physical interaction with the glass, which prevents any deformation or breakage. This high-power, short-pulse laser is highly efficient and allows for incredibly fine details.

Key Benefits:

- Ultimate Precision: Achieve micro-sized holes with accuracy down to the micron level, ideal for delicate glass types.

- Non-Touch, Non-Damaging: No risk of cracks or breaks, as the process is entirely non-contact.

- Fast and Efficient: Drill multiple holes in seconds—perfect for high-volume production.

- Versatile: Handles everything from thin automotive glass to thicker decorative glass and electronics glass.

- Clean Results: Laser technology ensures that edges are smooth and clear, minimizing post-processing.

Technical Parameters

| Parameter | 120W Laser | 200W Laser |

|---|---|---|

| Laser Type | Fiber Laser | Fiber Laser |

| Laser Power | 120W | 200W |

| Applicable Materials | Glass, Ultra-Clear Glass, 3-6mm Thin Glass | Glass, Ultra-Clear Glass, 3-6mm Thin Glass |

| Max Hole Depth | 1mm – 12mm | 1mm – 12mm |

| Max Hole Diameter | Within 80mm | Within 80mm |

| Drilling Speed | Up to 3000mm/min | Up to 4000mm/min |

| Beam Quality | <1.5M² | <1.5M² |

| Laser Frequency | 10-100kHz | 10-100kHz |

| Repeatability Accuracy | ±0.01mm | ±0.01mm |

| Cooling System | Water Cooling System | Water Cooling System |

| Applications | Electronics, Optics, Artistic Glass, Architectural Glass Processing | Electronics, Optics, Artistic Glass, Architectural Glass Processing |

| Control System | Professional software supporting automation and programming control | Professional software supporting automation and programming control |

Why Choose Glass Laser Drilling? Unlike traditional drilling methods that can cause cracks, chips, or even breakage, the Glass Laser Drilling Machine ensures flawless results without the risk of damage. It’s the perfect choice for drilling holes in smartphone displays, automotive glass, decorative glass, and more.

Ready to elevate your glass drilling process? The Glass Laser Drilling Machine combines speed, precision, and innovation, making it the ideal choice for all your glass drilling needs.

The Power of the Glass Laser Drilling Machine

If you’re serious about glass drilling, the Glass Laser Drilling Machine is the tool you’ve been waiting for. Here’s why:

1. Unmatched Precision

Forget the guesswork. With laser technology, you get precise, micro-sized holes every time. Whether you’re drilling through thin glass or thicker panels, you’ll always get the accuracy you need.

2. Non-Touch, No Damage

Unlike traditional drilling, there’s no physical contact with the glass. This non-touch process means no cracks, no chips, and no risk of breaking your glass. Simply clean, accurate results without any hassle.

3. Super Fast, Super Efficient

Time is money, and this machine saves you both. The Glass Laser Drilling Machine can drill multiple holes in seconds, making your production faster and more efficient. Get more done, in less time.

4. Perfect for Any Glass Type

Whether it’s automotive glass, decorative glass, or electronic glass, this machine handles it all. Thin sheets, thick panels, and everything in between—this machine is versatile enough to tackle any project.

5. No Post-Processing Needed

With laser drilling, you get smooth, clean holes every time. No need for extra polishing or cleaning up. Once the hole’s drilled, it’s ready to go. Fast. Simple. Efficient.

6. Eco-Friendly and Cost-Effective

The Glass Laser Drilling Machine doesn’t use any consumables and creates no waste. It’s an eco-friendly solution that also saves on costs. You’re getting the job done without harming the environment or breaking the bank.

7. Long-Lasting Durability

This isn’t a “one and done” tool. With minimal maintenance and long-lasting durability, the Glass Laser Drilling Machine is built to keep working for years—keeping your operation running smoothly without constant repairs.

Why Wait? Get Your Glass Laser Drilling Machine Today.

Ready to revolutionize your glass drilling? With the Glass Laser Drilling Machine, you get speed, precision, and reliability—all in one. Don’t settle for less. Get the best.

Glass Materials You Can Drill with Our Glass Laser Drilling Machine

Our powerful Glass Laser Drilling Machine is designed to drill and cut a wide range of glass materials with precision and efficiency. Whether you’re working with soda-lime glass, high borosilicate glass, quartz glass, or ultra-white glass, our machine offers superior results every time.

🔹 Soda-Lime Glass (Normal Glass / Float Glass)

The most common type of glass, used in everything from windows to mirrors. Our glass laser drilling machine ensures clean, precise holes in soda-lime glass, perfect for large-scale production in the construction, automotive, and consumer goods industries.

🔹 High Borosilicate Glass

With its thermal shock resistance, high borosilicate glass is ideal for laboratory equipment and kitchenware. The glass laser drilling machine easily handles this material, creating smooth holes without compromising the glass’s strength or structure.

🔹 Quartz Glass

Known for its durability and optical clarity, quartz glass is often used in electronics, optics, and semiconductors. The glass laser drilling machine provides ultra-precise drilling, ensuring the holes are clean and the material’s properties remain intact.

🔹 Ultra-White Glass

Used in high-end displays and decorative items, ultra-white glass requires precise drilling to maintain clarity. With our glass laser drilling machine, you can achieve perfectly drilled holes without damaging the glass, ensuring your final product is both functional and aesthetically pleasing.

Why Choose Our Glass Laser Drilling Machine for These Glass Materials?

- Non-Contact Technology: The glass laser drilling machine eliminates physical contact, ensuring no risk of cracks, chips, or distortion.

- Unmatched Precision: Our machine provides highly accurate drilling, perfect for micro-holes in various glass types.

- Versatile Compatibility: From soda-lime glass to ultra-white glass, the glass laser drilling machine can handle all your drilling needs.

- Efficient and Fast: Boost your production efficiency with quick, reliable drilling that doesn’t sacrifice quality.

These are just some of the glass materials that benefit from the advanced capabilities of our glass laser drilling machine. Whether you’re working with soda-lime glass, borosilicate, quartz, or ultra-white glass, our machine offers the precision, efficiency, and quality that you need for any project.

Frequently Asked Questions (FAQ)

1️⃣ What is a Glass Laser Drilling Machine used for?

A Glass Laser Drilling Machine is specifically designed for precise drilling of holes in glass and similar materials. It uses laser technology to create clean, accurate holes without causing cracks or damage to the glass surface. This machine is ideal for applications in electronics, automotive, jewelry making, and decorative glasswork.

2️⃣ How does a Glass Laser Drilling Machine work?

The laser drilling process involves focusing a high-powered laser beam onto the glass surface to melt or vaporize small sections of the material, creating a hole. The machine ensures precision and can create microscopic holes in thin glass with minimal heat affected zones, preventing any damage to the surrounding areas.

3️⃣ What types of glass can be drilled with this machine?

This machine is designed to work with various types of glass, including borosilicate glass, clear glass, colored glass. It’s perfect for drilling small to medium-sized holes with great precision and accuracy.

4️⃣ Is the machine capable of drilling different hole sizes?

Yes, the Glass Laser Drilling Machine can create holes of various sizes, ranging from microscopic holes (0.1mm) to larger diameters, depending on the machine’s specifications. The laser system provides great flexibility, allowing you to drill precise holes in multiple diameters as needed.

5️⃣ What industries benefit from using a Glass Laser Drilling Machine?

The Glass Laser Drilling Machine is highly beneficial for several industries, including:

- Electronics (drilling holes for sensors, touchscreens, and circuit boards)

- Jewelry making (creating holes in gemstones or decorative glass)

- Automotive (drilling holes for sensors, mirrors, and windows)

- Solar energy (glass drilling for solar panel components)

- Architectural and decorative applications (engraving and drilling for custom glass art)

6️⃣ Can the machine create holes without damaging the glass?

Yes, one of the key benefits of the Glass Laser Drilling Machine is its ability to drill holes without causing cracks, chips, or fractures. The precision laser beam minimizes heat distribution and focuses only on the material being drilled, ensuring the glass remains intact and undamaged.

7️⃣ How precise is the hole drilling with this machine?

The Glass Laser Drilling Machine offers extremely high precision, with the ability to drill holes as small as 0.1mm in diameter. The laser beam’s focus allows for intricate and detailed drilling, making it perfect for high-precision applications like electronics and fine jewelry.

8️⃣ Is the machine easy to operate?

Yes, the Glass Laser Drilling Machine is typically equipped with an intuitive user interface, making it easy to set parameters such as hole size, depth, and power. Many machines also offer automation features to further simplify operation, ensuring minimal user intervention.

9️⃣ Does the machine require any special maintenance?

The machine requires minimal maintenance. It’s important to regularly clean the laser lens, check the cooling system, and ensure the machine is operating in a dust-free environment to maintain its precision. Periodic checks on the system’s laser module are also recommended for optimal performance.

🔟 Can the Glass Laser Drilling Machine work on very thin glass?

Yes, this machine excels in drilling on thin glass with microscopic precision. It’s perfect for creating small holes or perforations in thin glass materials commonly used in electronics and jewelry, ensuring no cracks or damage to the glass.

1️⃣1️⃣ What are the power requirements for the machine?

The Glass Laser Drilling Machine generally operates on standard industrial power sources, with power requirements typically ranging from 200W to 500W, depending on the machine’s model and capabilities. Some machines also offer options for low power consumption for smaller applications.

1️⃣2️⃣ Is the machine safe to operate?

Yes, the Glass Laser Drilling Machine is designed with multiple safety features, including enclosed operating areas, laser safety shutters, and emergency stop buttons. It’s important to follow the manufacturer’s safety guidelines and wear appropriate protective gear when operating the machine.

1️⃣3️⃣ How fast can the machine drill holes?

The drilling speed depends on the hole size and glass thickness. However, the laser drilling process is generally fast, with the ability to drill hundreds of holes in a short time, making it ideal for both small-scale and mass production applications.

1️⃣4️⃣ What are the benefits of using a Glass Laser Drilling Machine over traditional methods?

Using a laser drilling machine offers several advantages over traditional methods such as mechanical drilling or chemical etching:

- Higher precision: Laser drilling provides extremely accurate hole sizes.

- Minimal heat damage: The laser’s precision minimizes heat distribution, preserving the integrity of the glass.

- No tooling wear: Unlike mechanical methods, there’s no tool wear, ensuring consistent performance.

- Faster processing: Laser drilling can be done quickly and with less manual effort, improving production efficiency.

Glass Drilling Laser Machine Working Video

Request a Quote for a Mini Fiber Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

Demo videos of 100W mini fiber laser engraving cutting machine

August 5, 2023 /0 Comments/in Blog /by lindaImpoortant:You need to Know about fiber laser cleaning machine power

July 23, 2023 /0 Comments/in Blog /by lindaTrolley-Type Handheld Fiber Laser Cleaning Machine Laser Rust Remover

July 12, 2023 /0 Comments/in Products /by linda

100W 200W Trolley-Type Handheld Fiber Laser Cleaning Machine

100W Trolley-Type Handheld Fiber Laser Cleaning Machine also called Laser Rust Remover Rust Laser Removal Machine

The laser cleaning machine is a portable integrated design, a super integrated injection molding chassis, a buffer design, compression, drop and wear resistance. Trolley-type chassis can be carried on high-speed train and flight.

It can work offline and can be used immediately after power on.

The cleaning head is extremely lightweight, 620g only (not include delivery cable), and can be operated by hand for a long time.

Machine Photos

Fiber Laser Cleaning Machine Laser Rust Paint Coating Removal Machine Laser Cleaner

200W Portable Laser Cleaning Machine Fiber Laser Cleaner, Efficiently Remove Metal Rust, Oil Stains, Wood Paint, Coating, Oxide Layer without Damaging the Substrate.

Compared with continuous type laser cleaning machine, it is more suitable for higher precision requirements cleaning such as mold cleaning.

Product Features

1. Trolley-type chassis design, super integrated injection molding chassis, stable struction and wearable.

2. Collimated laser beam output, beam size customizable (default 4mm).

3. 620g light weight cleaning head, and can be operated by hand for a long time.

4. Patented red light assisted focus technology, can adjust the focus position according to different focus lenses.

5. Wireless control Pad, can realize parameter setting and emission control remotely, and update parameters at any time.

6. With the Characteristics of Precise Positioning, It can Meet the Processing of a Variety of Modeling Workpieces and Achieve Efficient Cleaning.

| Model | SL-FC-100/200W |

| Output Method | Pulsed/CW |

| Delivery Cable Length(m) | 5 |

| Average Output Power(W) | >100 |

| Cooling Method | Air Cooled |

| Power Supply Voltage(V) | 110V-240V |

| Power Consumption(W) | <450 |

Advantage of the Fiber laser cleaning machine

The laser cleaning machine is a portable integrated design, a super integrated injection molding chassis, a buffer design, compression, drop and wear resistance. Trolley-type chassis can be carried on high-speed train and flight.

It can work offline and can be used immediately after power on

Collimated laser beam output, beam size customizable (default 4mm).

The cleaning head is extremely lightweight, 620g only (not include delivery cable), and can be operated by hand for a long time

Patented red light assisted focus technology, can adjust the focus position according to different focus lenses

Wireless control, can realize parameter setting and emission control remotely, and update parameters at any time

Trolley-type chassis design, can be carried on high-speed train and flight easily with 28kg full weight.

Super integrated injection molding chassis, cushioning design, stable structure, Wearable, shockproof and drop resistance.

Pulse laser cleaning machine, in addition to conventional surface cleaning, the machine has obvious effect on high temperature resistant coating and metal coating.

Application Material

Portable and lightweight, flexible and adjustable parameters, wireless control, etc., which can efficiently remove rust, stains, and oil on the surface of the workpiece, Plating, etc;

Can be applied to mechanical processing, cultural relics restoration, mold cleaning, food processing, electronic circuits and other industries;

With the characteristics of precise positioning, it can meet the processing of a variety of modeling workpieces and achieve efficient cleaning.

Application Area

Aviation,Electronic Machinery,Rubber Mould,Equipment Manufacturing,Auto Parats,Food Processing…

200W 300W Pulsed fiber laser cleaing machine

July 10, 2023 /0 Comments/in Products /by linda

200W 300W Pulsed fiber laser cleaing machine

Safe, Chemical-Free Cleaning for Complex and Delicate Surfaces

Pulsed Fiber Laser Cleaning Machine – Precision, Safety, and Efficiency

Our Pulsed Fiber Laser Cleaning Machine, available in 100W, 200W, and 300W models, uses advanced pulsed laser technology to remove rust, paint, oil, coatings, and contaminants from both metal and non-metal surfaces. Unlike continuous laser systems, it delivers controlled bursts of energy, preventing surface damage and ensuring zero harm to the material.

With its compact, portable, and handheld design, this laser cleaner is easy to move and operate in various settings. It’s perfect for industries requiring high-precision cleaning without chemicals or abrasives, providing eco-friendly, fast, and efficient results.

Whether you’re in need of rust removal or surface restoration, our Laser Rust Remover helps you maintain product quality while driving business growth.

Machine Photos of pulsed laser cleaning machine

SISMAR LASER Pulsed Fiber Laser Cleaning Machine: Precision, No Damage, and Superior Cleaning Solution

In industrial production, surface cleanliness is not just a matter of appearance—it directly impacts product quality and longevity. Traditional cleaning methods often force you to choose between effectiveness and risk: chemical cleaning leads to pollution, while mechanical cleaning can damage delicate surfaces. So, when dealing with stubborn rust or paint removal, have you ever struggled to find a solution that ensures both effectiveness and safety?

SISMAR LASER Pulsed Fiber Laser Cleaning Machine is here to solve your problems.

1.Pain Points:

- You need to remove tough paint and rust but fear damaging the precision components or underlying colors.

- You need cleaning without leaving a trace, especially on intricate parts where even the slightest scratch or damage can affect performance.

- Traditional methods using chemicals or high-pressure could leave secondary contamination or increase post-cleaning costs.

2.Solution:

The SISMAR LASER Pulsed Fiber Laser Cleaning Machine uses high-efficiency pulsed laser beams to precisely remove surface contaminants, including paint, rust, and debris, without the need for chemicals or physical contact. By emitting short, intense laser pulses, it vaporizes contaminants instantly, leaving the base color intact and cleaning with precision. Each cleaning session feels like a delicate restoration of the product’s surface, not a harsh grind. Perfect for high-precision components, electronics, and even artwork.

With SISMAR LASER Pulsed Fiber Laser Cleaning Technology, you can:

| # | Feature | Description |

|---|---|---|

| 1 | Remove Contaminants Completely | Even the toughest rust and paint are no match. |

| 2 | Preserve the Surface Integrity | Precise control of laser energy ensures no damage to the base color or delicate craftsmanship. |

| 3 | Be Efficient and Eco-Friendly | No chemicals, no high-pressure water—avoiding pollution and additional post-treatment costs. |

| 4 | Enjoy Versatile Applications | Whether it’s steel, aluminum alloys, electronic components, or artwork, SISMAR LASER offers the perfect solution. |

Don’t let traditional cleaning methods limit you. Choose the SISMAR LASER Pulsed Fiber Laser Cleaning Machine and let every detail shine with precision, quality, and efficiency.

What you’re after is more than just cleanliness—it’s perfection without compromise. Experience SISMAR LASER Pulsed Fiber Laser Cleaning Machine today, and make cleaning more efficient, precise, and eco-friendly.

3.Parameter of Pulsed laser cleaning machine

Handheld Laser Rust Remover Parameters |

||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Model | SL-C200/300 | |||||||||||

| Laser power | 200W/300W | |||||||||||

| Working Voltage | 110/220V 50/60 HZ | |||||||||||

| Laser Working Mode | Pulse | |||||||||||

| Laser Source | JPT | |||||||||||

| Average Laser Power | >300W | |||||||||||

| Power Instability | <5% | |||||||||||

| Maximum Pulse Energy | 15mJ | |||||||||||

| Pulse Width | 2-500ns | |||||||||||

| Cooling Method | Water Cooling | |||||||||||

| Power Regulation Range(%) | 0-100( Gradient Adjustable) | |||||||||||

| Repeat Frequency(kHz) | 1-4000(Gradient Adjustable) | |||||||||||

| Fiber Cable Length | 5m | |||||||||||

| Cleaning Head Weight (including isolator) | <1.5Kg | |||||||||||

| Working Environment Humidity | ≤80% | |||||||||||

| Working Environment Temperature | 10℃~40℃ | |||||||||||

| Machine Dimensions (Length, width and height) | About 860mm*410mm*700mm | |||||||||||

| Machine Weight | About 80Kg | |||||||||||

Laser Cleaning Head Parameters |

||||||||||||

| Cleaning Head Weight | Less Than 1.25Kg | |||||||||||

| Scanning Width | 0-145mm Optional | |||||||||||

| Scanning Frequency | Not Less Than 300Hz | |||||||||||

| Maximum Scan Line Speed | About 30m/s | |||||||||||

| Maximum Scanning Speed | 20000mm/s | |||||||||||

| Light Transmittance | ≥98% | |||||||||||

| Laser Power Adjustment | 10%-100% | |||||||||||

| Focal Length | Standard configuration 210mm (160mm/254mm/330mm/420mm optional) | |||||||||||

| Incident Spot Diameter | ≤10mm | |||||||||||

| Cable Length | Standard configuration of 10m | |||||||||||

🚀 1️⃣ Why Pulsed Fiber Laser Cleaning Machine is the Future of Surface Cleaning

Are you tired of cleaning methods that are too harsh on your equipment or just don’t deliver the results you need? Traditional cleaning methods—like chemicals, abrasives, or high-pressure washing—can damage your products and lead to costly repairs. If you need an effective, eco-friendly, and precise solution, look no further than the Pulsed Fiber Laser Cleaning Machine.

This cutting-edge technology is revolutionizing the way industries clean their surfaces. From rust removal to coating removal, pulsed fiber laser cleaning offers a safe, efficient, and environmentally friendly approach to cleaning a variety of materials. Let’s dive into how this powerful machine can benefit key industries.

✨ 2️⃣ Key Applications of Pulsed Fiber Laser Cleaning Machine

⚙️ 2.1 Rust and Oxidation Removal in the Metal Industry

Rust and oxidation are a common problem in industries that deal with metal components. Pulsed fiber laser cleaning quickly removes corrosion without damaging the underlying surface, ensuring that your materials stay intact and ready for use. This is especially important for automotive manufacturing, construction, and metal fabrication, where high-quality materials are essential.

Benefits:

- Fast, efficient rust removal

- Preserves material integrity

- No chemicals or abrasive materials involved

⚡ 2.2 Paint and Coating Removal in the Automotive and Aerospace Industries

The Pulsed Fiber Laser Cleaning Machine is ideal for removing paint, coatings, and adhesives without harming delicate surfaces. In industries like automotive manufacturing and aerospace, precise paint removal is necessary to prepare parts for refinishing or further processing.

Benefits:

- Removes paint and coatings with laser precision

- No risk of damaging intricate parts

- Eco-friendly solution, no harmful chemicals

💻 2.3 Surface Preparation for Electronics

When it comes to cleaning electronic components, such as circuit boards or delicate parts, the Pulsed Fiber Laser Cleaning Machine offers a non-contact solution. The laser’s ability to clean without physical touch ensures sensitive components are not damaged, making it perfect for the electronics manufacturing industry.

Benefits:

- Non-contact, preserving delicate components

- Precise cleaning without damage

- Ideal for small, complex surfaces

🔧 2.4 Mold and Die Cleaning in Manufacturing

For industries involved in plastic molding or metal casting, keeping molds and dies free from contaminants is crucial. The Pulsed Fiber Laser Cleaning Machine easily removes build-up of rubber, metal, or plastic residue without wear and tear, extending the life of your molds and dies.

Benefits:

- Removes contaminants quickly and effectively

- No abrasive materials, preserving mold quality

- Increases efficiency by reducing downtime

🏺 2.5 Historical Artifact Restoration in Museums and Art Conservation

The gentle yet effective nature of Pulsed Fiber Laser Cleaning makes it the perfect solution for cleaning delicate historical artifacts. Whether it’s removing soot from sculptures or rust from metal objects, this technology helps preserve and restore items in art conservation and museum restoration.

Benefits:

- Safe for delicate, priceless items

- Gentle cleaning process maintains historical value

- Eco-friendly, no chemicals used

🔥 3️⃣ Why Choose Pulsed Fiber Laser Cleaning?

The Pulsed Fiber Laser Cleaning Machine isn’t just another cleaning tool—it’s a game changer. Unlike traditional methods, it offers several unbeatable advantages:

- Precision: Laser cleaning ensures every surface is treated exactly as it needs to be, without damaging the underlying material.

- Efficiency: You can remove rust, coatings, and contaminants faster than ever before.

- Eco-Friendly: No need for harsh chemicals or solvents, making it an environmentally conscious choice.

- Cost-Effective: It reduces the need for manual labor, abrasive tools, and expensive chemicals, saving you money in the long run.

💡 4️⃣ Take Your Cleaning Process to the Next Level

Whether you’re in metal manufacturing, automotive production, or electronics, the Pulsed Fiber Laser Cleaning Machine offers an advanced, reliable, and eco-friendly solution to your cleaning needs. By eliminating the problems of traditional methods and offering precision and efficiency, this machine is set to transform the way industries approach surface cleaning.

Ready to experience the future of cleaning? Choose the Pulsed Fiber Laser Cleaning Machine and ensure your equipment stays in top shape, with minimal environmental impact and maximum efficiency.

FAQ – Pulsed Fiber Laser Cleaning Machine

1. How does the Pulsed Fiber Laser Cleaning Machine work?

Answer:

The Pulsed Fiber Laser Cleaning Machine uses short, high-energy laser pulses to interact intensely with the surface contaminants like rust, paint, and oxides. The laser energy causes these contaminants to evaporate or fragment almost instantly. This non-contact cleaning method effectively removes surface dirt without damaging the base material. Laser cleaning is not only fast and efficient but also free from chemical pollutants.

2. How often does the Pulsed Fiber Laser Cleaning Machine need maintenance?

Answer:

Typically, the maintenance cycle for a Pulsed Fiber Laser Cleaning Machine is every 6 months to 1 year. The exact maintenance schedule depends on usage frequency and environmental conditions. Routine maintenance includes checking the fiber optic cables, laser source, cooling system, and control systems to ensure proper functioning. It’s recommended to regularly clean the machine’s interior and keep the laser output port clean for optimal performance.

3. What types of materials are suitable for cleaning with a Pulsed Fiber Laser Cleaning Machine?

Answer:

The Pulsed Fiber Laser Cleaning Machine is suitable for a wide range of materials, especially metals. Common materials include:

- Steel, aluminum alloys, copper, etc.: Removing rust, paint, oxides, and more.

- Plastics and rubber: Cleaning surface contaminants or old coatings.

- Precision electronic components: Non-contact cleaning to avoid damage to delicate structures.

- Art and historical artifacts: Gentle cleaning to remove surface dirt while preserving the original appearance.

4. What impact does laser cleaning have on surfaces?

Answer:

The Pulsed Fiber Laser Cleaning Machine has minimal impact on surfaces. Since the cleaning process is non-contact, it doesn’t cause physical abrasion or scratching. By precisely controlling the laser pulses and power, the cleaning action targets only the contaminants without damaging the underlying material, making it ideal for delicate and high-precision cleaning tasks.

5. Is laser cleaning environmentally friendly?

Answer:

Yes, Pulsed Fiber Laser Cleaning is an environmentally friendly method. Unlike traditional chemical cleaning or high-pressure washing, laser cleaning doesn’t require any chemical solvents, and it doesn’t generate harmful waste or pollutants. It reduces the use of chemicals and prevents secondary pollution, aligning with modern eco-friendly standards.

6. Is laser cleaning effective for all types of contaminants?

Answer:

The Pulsed Fiber Laser Cleaning Machine is highly effective in removing a variety of contaminants, including rust, paint, oxides, dirt, adhesives, and other industrial residues. However, some stubborn contaminants (like deeply embedded substances) may require multiple cleaning sessions. Laser power and frequency can be adjusted depending on the cleaning task to optimize results.

7. Is the operation of the Pulsed Fiber Laser Cleaning Machine complex?

Answer:

No, operating the Pulsed Fiber Laser Cleaning Machine is simple and intuitive. Users can control the machine through a touchscreen or computer software. The cleaning process can be performed in automatic mode, reducing the need for specialized skills. Most laser cleaning machines also come with safety features to ensure safe operation throughout the cleaning process.

8. How fast is the cleaning speed of the Pulsed Fiber Laser Cleaning Machine?

Answer:

The cleaning speed of the Pulsed Fiber Laser Cleaning Machine is incredibly fast, typically capable of cleaning several square meters per minute, depending on the type of contaminants and the surface condition. For light contamination, the cleaning speed is faster; for more stubborn stains, it might take a little longer, but laser cleaning still remains much more efficient compared to traditional methods.

9. Does laser cleaning require a special operating environment?

Answer:

The Pulsed Fiber Laser Cleaning Machine is adaptable, but to ensure optimal performance, it is best used in a well-ventilated environment with moderate temperature. Avoid extreme humidity or high temperatures. Most machines are equipped with cooling systems to maintain the device within a suitable operating temperature range.

10. What is the lifespan of the Pulsed Fiber Laser Cleaning Machine?

Answer:

The Pulsed Fiber Laser Cleaning Machine typically lasts over 10 years. The lifespan depends on factors like usage frequency, environmental conditions, and regular maintenance. With proper care and timely repairs, the laser cleaning machine can maintain its high efficiency and continue to provide reliable cleaning service for businesses over the long term.

These FAQs are designed to help you better understand the Pulsed Fiber Laser Cleaning Machine, its benefits, and how it can enhance your cleaning process. Whether you’re in the automotive, manufacturing, or electronics industries, this machine offers a high-performance, eco-friendly solution for your cleaning needs.

Working Video of Pulsed Laser Cleaning Machine

Request a Quote for a Laser cleaning Machine

SISMAR LASER has Laser Cleaning Machine and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser cleaning system or an excellent choice for your first laser machine.

Request a quote for a high-quality laser cleaning that exceeds your expectations. You can also schedule a demo to see how green laser cleaning works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting/welding machines.

4 in 1 Handheld Metal Laser Welding Machine (1500W, 2000W, 3000W)

July 7, 2023 /0 Comments/in Products /by linda

4 in 1 Handheld Metal Laser Welding Machine (1500W, 2000W, 3000W)

Transform Your Workflow with the 4-in-1 Handheld Fiber Laser Welding Cleaning Machine 🚀

Tired of juggling multiple machines for different tasks? The 4-in-1 Handheld Fiber Laser Welding Cleaning Machine brings it all together in one powerhouse tool. Weld, clean, remove rust, and strip paint—all with the precision and speed of cutting-edge fiber laser technology.

Whether you’re dealing with metal, rust, coatings, or delicate surfaces, this machine guarantees fast, efficient, and eco-friendly results every time. No chemicals. No mess. Just perfect, polished surfaces. Ideal for automotive, manufacturing, and construction industries, this tool will save you time, reduce costs, and boost your productivity.

Stop wasting time and energy—take your work to the next level with this all-in-one solution. You won’t believe how easy it is!

Laser Metal Cleaner is with a very compact portable and handheld design which is easy to move from one place to another one.

It is widely used in industries that require high precision like zero harm to the material while removing rust, paint, oil, film, and coating from the surface. Our handheld laser cleaner and Portable Laser Cleaning Machine will help you o drive business growth!

Photos of 4-In-1 handheld fiber laser welding Cleaning machine

Unlock Unmatched Efficiency with the 4-in-1 Handheld Metal Laser Welding Machine: The Ultimate Tool for Your Metalworking Needs

Are you ready to revolutionize your metalworking process? The 4-in-1 Handheld Metal Laser Welding Machine is here to deliver maximum precision, cost savings, and efficiency in one device. Whether you’re working in manufacturing, automotive, metalworking, or construction, this powerful machine combines four essential functions into one compact, portable solution.

Why Choose the 4-in-1 Handheld Metal Laser Welding Machine?

The 4-in-1 Handheld Laser Welding Machine is more than just a tool—it’s an investment in the future of your business. Here’s why:

| Feature | Details |

|---|---|

| Laser Welding | – Achieve strong, precise welds in stainless steel, carbon steel, aluminum, and more. – Minimizes heat distortion for cleaner and more consistent welds. – Easy-to-use controls reduce welding errors and save time. |

| Laser Cleaning | – Effortlessly remove rust, oil, paint, and contaminants from metal surfaces. – No chemicals or abrasives—just clean metal surfaces with ease. – Eco-friendly, cost-effective, and efficient, ideal for pre-welding cleaning. |

| Laser Cutting | – Cut metal sheets and pipes with high precision. – Ideal for hardware, electrical appliances, and sheet metal manufacturing. – Accurate cuts with minimal waste, saving materials and money. |

| Weld Seam Cleaning | – Ensures smooth, polished welds every time. – Achieve a perfect finish for all welding projects—no tedious manual cleanup required. |

Overall Benefit – The 4-in-1 Handheld Metal Laser Welding Machine is an investment in the future of your business, offering high precision, efficiency, and cost savings in one compact, portable device.

Key Features of the 4-in-1 Handheld Laser Welding Machine

| Feature | Details |

|---|---|

| 1. Multi-Functionality | – Combines four essential functions in one machine: Laser Welding, Laser Cleaning, Laser Cutting, and Weld Seam Cleaning. |

| 2. Portability | – Lightweight and handheld design for flexible operation. – Perfect for on-site and workshop use, adaptable to any environment. |

| 3. Precision | – Fiber laser technology ensures high precision, minimal heat distortion, and consistent results. – Achieve professional finishes in welding, cleaning, cutting, and seam cleaning. |

| 4. Energy Efficient | – Low power consumption compared to traditional methods. – Longer operational hours with lower energy bills. |

| 5. Cost-Effective | – Save money by eliminating the need for multiple machines. – More functions, less investment, enhancing work efficiency. |

Real-World Applications: Transform Your Workflow

- Manufacturing: Ideal for welding, cutting, cleaning, and polishing metal components.

- Automotive: Perfect for repairing, maintaining, and cleaning automotive parts.

- Metalworking: From mold cleaning to surface preparation, this tool covers all your needs.

- Construction: Efficient for welding metal structures and surface cleaning.

Why You Should Invest in the 4-in-1 Handheld Laser Welding Machine NOW

This is your chance to enhance your productivity, reduce costs, and improve the quality of your work with one device. Here’s how:

- Increase Efficiency: Reduce time spent on each task with the multi-functional design.

- Lower Operational Costs: Save energy and eliminate the need for multiple machines.

- Enhance Your Output: Produce cleaner, stronger, and more precise results with ease.

- Eco-Friendly: Stop using harmful chemicals with the laser cleaning feature—better for the environment, better for your business.

Take the Next Step: Order the 4-in-1 Handheld Laser Welding Machine Today!

Don’t wait—this tool is designed to give you everything you need to level up your metalworking operations. Take advantage of the fiber laser welding machine‘s power and versatility to improve your workflow, reduce costs, and boost quality.

Ready to Upgrade Your Metalworking Process?

Order now and experience the power, precision, and portability of the 4-in-1 Handheld Metal Laser Welding Machine. Transform your workflow and become the industry leader with cutting-edge fiber laser technology.

Cleaning gun

Handheld design Flexible angle

| Category | Continuous Laser Cleaning | Pulsed Laser Cleaning |

|---|---|---|

| Working Principle | Emits a continuous laser beam to remove surface contaminants like rust and dirt through prolonged heating. | Uses short, high-energy laser pulses at high frequencies to remove contaminants in brief, intense bursts. |

| Advantages | – Ideal for large surface areas and rapid cleaning. – Efficient for bulk cleaning with quick results. |

– Non-damaging: Removes contaminants without heating or damaging the material. – Ideal for precision cleaning of sensitive and delicate materials. – Offers high-quality results. |

| Disadvantages | – Thermal damage: Prolonged heating may cause thermal damage, overheating, or distortion of sensitive materials. | – Slower compared to continuous lasers, but offers better precision and surface quality. |

| Best For | Large surface areas, routine or bulk cleaning. | High-precision applications like electronics, aerospace, or high-end metal parts. |

| Efficiency | High-speed cleaning, suitable for larger areas, but may risk damaging sensitive materials. | Slower but excels in precision, detail, and material protection. |

| Key Applications | Large-area rust removal, paint stripping, general surface cleaning. | Precision cleaning of delicate or high-precision materials, rust or paint removal on sensitive parts. |

| Category | Single Mode Laser | Multi Mode Laser |

|---|---|---|

| Beam Characteristics | Small spot size, high focus, high beam quality, single propagation mode. | Larger spot size, multiple propagation modes, lower beam quality, higher power. |

| Advantages | – High precision and energy density. – Ideal for fine engraving, micro-welding, and precision cleaning. – Superior control for intricate tasks. |

– Higher beam strength, ideal for large-area cleaning or welding. – Lower cost compared to single mode lasers. |

| Disadvantages | – Costlier compared to multi-mode lasers. – Lower power output, suitable for high-precision applications. |

– Less precision due to beam non-uniformity. – Best for applications where fine control is not critical. |

| Best For | High-precision cleaning, engraving, micro-welding, and delicate tasks. | Large-area cleaning, welding, or applications requiring high beam strength and lower precision. |

| Applications | Precision cleaning, micro-welding, fine engraving. | Large-area cleaning, industrial welding, rust removal on large surfaces. |

Related Keywords

- Laser cleaning machine

- Pulsed laser cleaning

- Continuous laser cleaning

- Single mode laser

- Multi mode laser

- High precision cleaning

- Laser rust removal

FAQ: 4-in-1 Handheld Fiber Laser Welding Cleaning Machine

1️⃣. What is a 4-in-1 Handheld Fiber Laser Welding Cleaning Machine?

The 4-in-1 Handheld Fiber Laser Welding Cleaning Machine combines four essential functions: welding, cleaning, rust removal, and paint stripping. Using advanced fiber laser technology, it offers precise, efficient, and eco-friendly solutions for a variety of industries, including automotive, manufacturing, and construction.

2️⃣. How does the fiber laser cleaning function work?

The laser cleaning function uses high-powered laser beams to remove rust, oxidation, and contaminants from metal surfaces without damaging the underlying material. The pulsed laser vaporizes unwanted materials, leaving a clean, smooth surface. This method is faster, more effective, and environmentally friendly compared to traditional cleaning techniques.

3️⃣. What types of materials can this machine work with?

The 4-in-1 machine is designed to work with a wide range of metal surfaces such as steel, aluminum, copper, brass, and stainless steel. It’s perfect for industries that require high-precision welding, cleaning, and maintenance of metal components.

4️⃣. Can this machine be used for rust removal and paint stripping?

Yes! The fiber laser cleaning function efficiently removes rust, oxidation, and dirt from metal surfaces. Additionally, the paint stripping feature helps remove coatings, adhesives, and paints without damaging the surface. It’s ideal for automotive, aerospace, and construction applications.

5️⃣. Is it easy to operate the 4-in-1 machine?

Absolutely! The handheld design and intuitive interface make this machine user-friendly. You don’t need advanced technical skills to operate it. Whether you’re a beginner or an expert, this tool allows you to achieve high-quality results with minimal effort.

6️⃣. How does it improve efficiency in my work?

This 4-in-1 machine replaces multiple machines and manual labor, providing a time-saving solution. With high-speed laser cleaning, precise welding, and paint removal capabilities, it significantly boosts productivity and reduces downtime in your operations.

7️⃣. Is this machine environmentally friendly?

Yes! The fiber laser technology is an eco-friendly solution because it requires no chemicals, solvents, or abrasives. It minimizes waste and reduces environmental impact compared to traditional cleaning methods.

8️⃣. What industries can benefit from the 4-in-1 Fiber Laser Welding Cleaning Machine?

This versatile tool benefits a variety of industries, including:

- Automotive Manufacturing

- Metal Fabrication

- Construction and Shipbuilding

- Aerospace and Aviation

- Electronics and Machinery

9️⃣. How does the 4-in-1 Fiber Laser Welding Cleaning Machine compare to traditional methods?

Unlike traditional methods that use chemicals or abrasives, the fiber laser machine offers a cleaner, faster, and safer solution. It provides precise results without physical contact, ensuring that delicate components are not damaged during cleaning or welding.

🔟. Is the 4-in-1 machine cost-effective?

Yes! By replacing multiple tools, reducing the need for chemicals, and lowering labor costs, the 4-in-1 Handheld Fiber Laser Welding Cleaning Machine is a cost-effective solution that improves productivity while maintaining high-quality results.

Video of Laser Rust Removal

Request a Quote for a Laser cleaning Machine

SISMAR LASER has Laser Cleaning Machine and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser cleaning system or an excellent choice for your first laser machine.

Request a quote for a high-quality laser cleaning that exceeds your expectations. You can also schedule a demo to see how green laser cleaning works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting/welding machines.

600*500mm Fiber Laser Cutting Machine

June 7, 2023 /0 Comments/in Products /by linda

Jewelry Fiber Laser Cutting Machine

600*500mm Fiber Laser Cutting Machine

The 600*500mm Fiber Laser Cutting Machine features a modular transmission system, offering faster cutting speeds, high precision, and easy maintenance. Its compact footprint makes it perfect for industries with limited space while still delivering high-performance cutting.

Ideal for the advertising industry (cutting large signs and logos) and the jewelry industry (cutting gold and silver with precision), it comes in 1000W, 1500W, and 2000W power options to handle different metal thicknesses. Suitable for metalworking, automotive, and signage applications, it efficiently cuts stainless steel, aluminum, and brass, all while saving valuable floor space.

600*500mm Fiber Laser Cutting Machine

Unlock Precision and Power with the 600*500mm Fiber Laser Cutting Machine

If you’re looking for a cutting machine that combines speed, precision, and a compact design, look no further: the 600*500mm Fiber Laser Cutting Machine is exactly what you need. This machine is perfect for industries that require high-performance cutting without taking up extra space. Whether you work in advertising, jewelry, or metallurgy, this machine gets the job done faster, better, and smarter.

Why is this machine a game-changer for your business?

1.Ultrafast Cutting with Modular Transmission Forget about slow machines with high maintenance from the past. The modular transmission system of this laser cutter offers higher cutting speeds and greater precision compared to traditional systems. That means you can handle more jobs, meet tight deadlines, and keep your clients satisfied.

| Feature | Description |

|---|---|

| Speed | Cut materials faster than traditional systems, saving valuable time on each project. |

| Precision | Achieve sharp, clean cuts, no matter how intricate the design. |

| Maintenance | Spend less time on repairs and more time focusing on what truly advances your business. |

2.Compact Design, Maximum Efficiency If space is limited in your workshop or factory, you’ll love the compact design of this machine. It’s designed to save space without sacrificing performance. So even in crowded environments, you can keep operating with a high-performance machine.

| Feature | Description |

|---|---|

| Small but Powerful | Its optimized design allows you to make the most of floor space while maintaining high cutting performance. You no longer have to choose between size and power. |

| Perfect for Small Spaces | Ideal for those with limited space but still need high-quality results. |

3.Versatility That Works for You Whether you’re cutting metal sheets, creating custom jewelry, or manufacturing custom signage, the 600*500mm Fiber Laser Cutting Machine is designed for a wide range of tasks. With power options of 1000W, 1500W, and 2000W, it offers flexibility to handle different materials and thicknesses.

| Application | Description |

|---|---|

| Custom Signage | Easily cut large signs, logos, and custom shapes, ideal for the advertising industry. |

| Jewelry | Work with gold, silver, and other precious metals to create intricate jewelry with flawless precision. |

| Metallurgy | Cut various thicknesses of metals like stainless steel, aluminum, and brass, ensuring clean, high-quality cuts every time. |

4.Built for Durability, Easy Maintenance Unlike older systems, the modular transmission design is not only faster and more precise but also reduces wear and tear. This means less downtime, translating to higher productivity and lower repair costs.

| Feature | Description |

|---|---|

| Effortless Maintenance | Keep your machine running at peak performance without the hassle of constant maintenance. |

| Long-Lasting Performance | Get the reliability you need from a machine capable of handling demanding workloads without failure. |

5.Maximum Results with Minimal Space The 600*500mm Fiber Laser Cutting Machine is designed to deliver maximum results without taking up much space. Whether you’re cutting thin sheets or thick plates, it handles the job with precision, speed, and efficiency.

Why Should You Invest in This Machine Right Now?

🔝1. Increase Your Productivity

This machine doesn’t just get the job done; it does it faster and better. This means you can take on more projects, meet customer demand, and increase your profits.

🏢 2.Save Space Without Compromising Performance

If your workspace is limited, this machine is the solution. It fits in tight spaces without sacrificing cutting power or precision. You get a high-performance tool in a compact design—both worlds at their best.

🌍3. Versatility for Every Industry

From advertising to metallurgy and jewelry, this machine works for a variety of industries, offering precision and quality every time. Whether you need to cut large signs, custom jewelry, or industrial parts, it’s designed to handle it all.

Conclusion: The Future of Laser Cutting is Here

The 600*500mm Fiber Laser Cutting Machine is more than just a tool; it’s a revolutionary investment for your business. With its high cutting speed, great precision, and compact design, this machine is made to boost productivity, save space, and help you deliver superior-quality results every time.

Don’t let outdated equipment hold you back. Take your business to the next level with the 600*500mm Fiber Laser Cutting Machine: your ultimate solution for fast, precise, and efficient laser cutting.

Here’s the detailed parameter table for the 600*500mm Fiber Laser Cutting Machine:

| Parameter | Specification | Why It Matters |

|---|---|---|

| Cutting Area | 600mm x 500mm (23.6″ x 19.7″) | Provides a spacious cutting area for large designs and materials like signs, logos, and jewelry without repositioning your workpiece. |

| Laser Power Options | 1000W, 1500W, 2000W | Allows you to cut various thicknesses of metals. Choose the right power for your cutting needs, from thin sheets to thicker plates. |

| Laser Source | Fiber Laser | 1064nm wavelength provides high efficiency and precision, ensuring optimal performance for metals like stainless steel, aluminum, and gold. |

| Cutting Speed | Up to 30,000mm/min | High-speed cutting ensures you finish projects faster, boosting productivity and meeting tight deadlines. |

| Positioning Accuracy | ±0.03mm | Ensures every cut is sharp and precise. Perfect for intricate designs and high-quality results in jewelry and custom signage. |

| Repetition Accuracy | ±0.02mm | Guarantees consistent precision across multiple cuts, making it ideal for batch production and high-volume cutting. |

| Cooling System | Water Cooling | Keeps the machine at an optimal temperature, preventing overheating during long cutting sessions and ensuring consistent quality and extended lifespan. |

| Material Compatibility | Stainless Steel, Carbon Steel, Aluminum, Brass, Copper, Gold, Silver | Cuts a wide range of materials for industries such as metalworking, signage, and jewelry. Perfect for all your cutting needs. |

| Software Compatibility | AutoCAD, CorelDRAW, Adobe Illustrator, and other CAD/CAM software | Works seamlessly with industry-standard design software, allowing for flexibility and integration into existing workflows. |

| Dimensions & Weight | 1950mm x 1450mm x 1200mm | Compact design for space-saving while offering sturdy construction for heavy-duty work. Weight: Approx. 1000kg (2205 lbs). |

| Power Supply | 220V ± 10%, 50/60Hz | Fits standard industrial power setups, ensuring stable performance and easy installation. |

| Maximum Material Thickness | Steel: Up to 8mm; Stainless Steel: Up to 6mm | Cuts medium to thick metals with ease, suitable for a range of applications from industrial parts to fine jewelry cutting. |

Why These Parameters Matter to Your Business

- Speed and Precision: High-speed cutting and tight accuracy mean faster production times and flawless results, even for the most detailed work.

- Versatile Material Handling: Whether you’re working with thin metal for signs or thicker plates for industrial parts, the machine handles it all with ease.

- Compact Yet Powerful: The space-efficient design doesn’t compromise on power, allowing you to run a high-performance operation in a limited workspace.

- Durable and Reliable: With a high-quality build and easy maintenance, this machine is designed to work hard for years, minimizing downtime and maximizing your ROI.

Unlock the Power of Precision: Fiber Laser Cutting Machines for Every Industry

If you’re looking for speed, precision, and versatility, the 600*500mm Fiber Laser Cutting Machine is the game-changer you need. Whether you’re creating stunning jewelry, cutting intricate metal parts, or producing high-quality advertising signage, this machine delivers flawless results every time.

| Industry | Applications | Why It Matters |

|---|---|---|

| 🔥 Advertising | Cutting large signs, logos, custom designs, and promotional materials. | Sharp, clean cuts in a single pass save time and money, while making your signage stand out with lasting impact. |

| 💍 Jewelry | Cutting and engraving gold, silver, platinum, and other precious metals. | Precision in every cut and intricate detail, ensuring flawless results with no imperfections. |

| ⚙️ Metalworking | Cutting stainless steel, brass, aluminum, and more for industrial parts and prototypes. | High-power laser cutting provides precision and efficiency, maximizing quality and minimizing waste. |

| 🚗 Automotive | Cutting automotive parts, components, and accessories. | Speed and accuracy deliver clean cuts to the tightest specs, ensuring faster production and exceptional quality. |

| 🔌 Electronics | Cutting and engraving circuit boards, enclosures, and metal casings. | Unbelievable precision for the smallest details, ensuring high-performance results with no compromises. |

| 🛠️ Signage | Creating custom signs, storefront displays, and decorative elements. | High-speed, precise cutting creates detailed designs with crisp, professional edges for impactful displays. |

| ✈️ Aerospace & Defense | Cutting and engraving metal parts, components, and prototypes. | Unparalleled accuracy for tough materials like aluminum and titanium, ensuring parts meet the highest standards. |

| 🎨 Art & Design | Creating custom artwork, decorative pieces, and engraving designs on metal. | Empowering artists to bring intricate designs to life with laser-like precision for perfect finishes. |

Why Choose the 600*500mm Fiber Laser Cutting Machine?

- ⚡ Fast, Efficient Cutting: Cut more projects in less time, boosting productivity and keeping your business ahead of the curve.

- 🎯 Precision Matters: Achieve clean, sharp cuts for even the most intricate designs. Your work will stand out with quality that speaks for itself.

- 🔧 Low Maintenance: Designed for effortless upkeep, so you can focus on what truly matters: growing your business.

- 🌍 Versatility: From advertising signage to aerospace parts, this machine adapts to all your cutting needs.

Get ready to level up your cutting game. The Fiber Laser Cutting Machine is more than just a tool—it’s your gateway to efficiency, precision, and versatility in every industry. Don’t wait—unlock the future of cutting today!

Laser Cutting Metal video

Request a Quote for a Fiber laser Cutting Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing Fiber laser cutting system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser cutting machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking cutting works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

CONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am

- EZCAD common errorMarch 18, 2025 - 2:09 am