Machine de sablage au laser pour miroir

/0 Comments/in Products /by linda

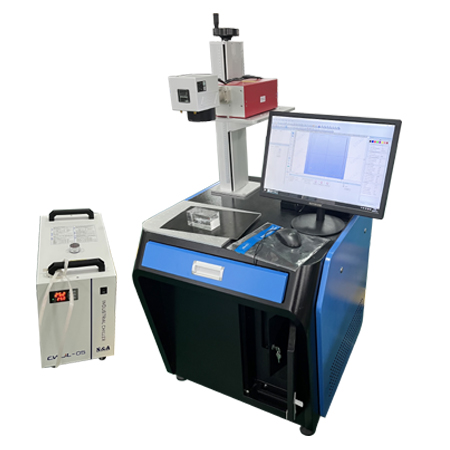

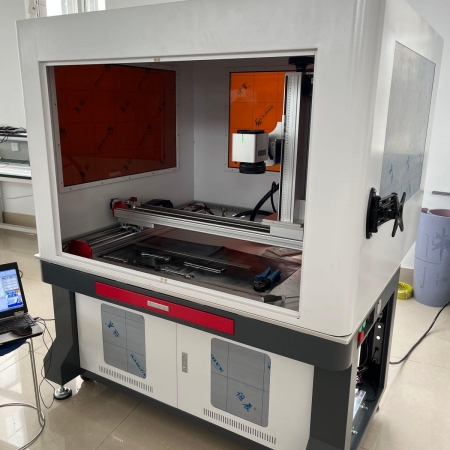

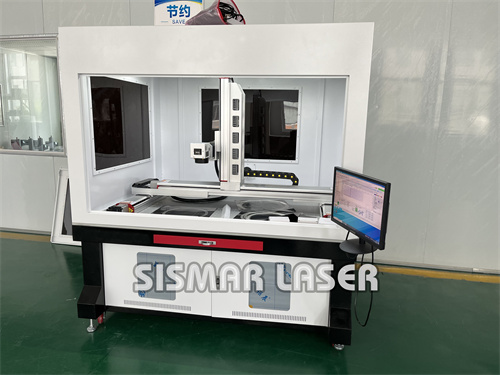

Machine de sablage au laser pour miroir 1300*2500 mm

Machine de gravure laser pour miroir grand format

Machine de sablage au laser pour miroir : Traitement de surface rapide, propre et précis

Vous recherchez une machine de sablage au laser pour miroir ? Cet outil puissant vous permet d’obtenir des finis givrés parfaits sur les miroirs et le verre, tout en facilitant le décapage de peinture, et ce, sans aucun désordre.

🚀 Pourquoi l’adopter ?

✅ Précision laser : Des résultats lisses et homogènes à chaque utilisation.

✅ Rapide & efficace : Idéal pour une production en grande quantité.

✅ Décapage de peinture : Élimine les revêtements et la peinture sans endommager la surface.

✅ Écologique : Sans poussière, sans produits chimiques, juste un travail propre.

✅ Faible entretien : Conçu pour durer avec un minimum de maintenance.

Si vous cherchez une solution fiable pour réaliser de magnifiques finis givrés et enlever facilement la peinture sur le verre ou les miroirs, cette machine est faite pour vous ! ✨

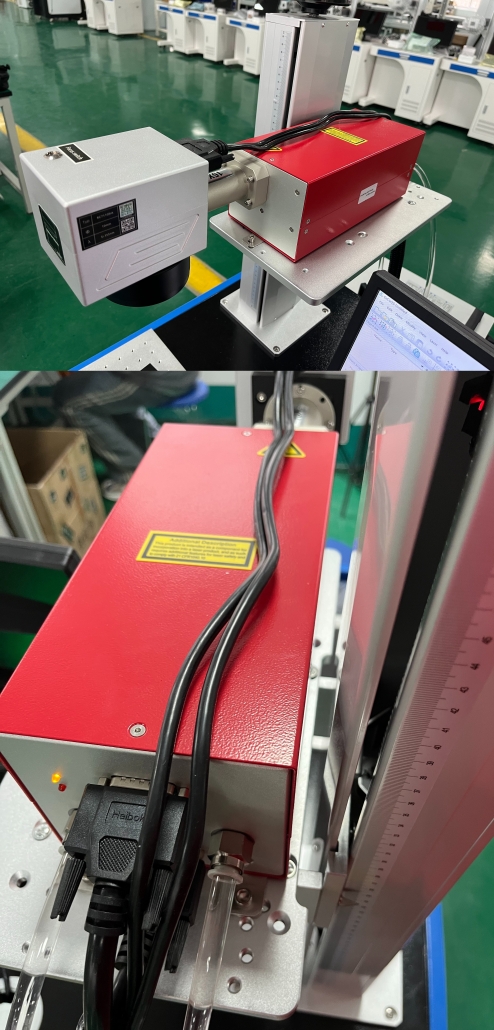

Photos de la machine de sablage au laser pour miroir

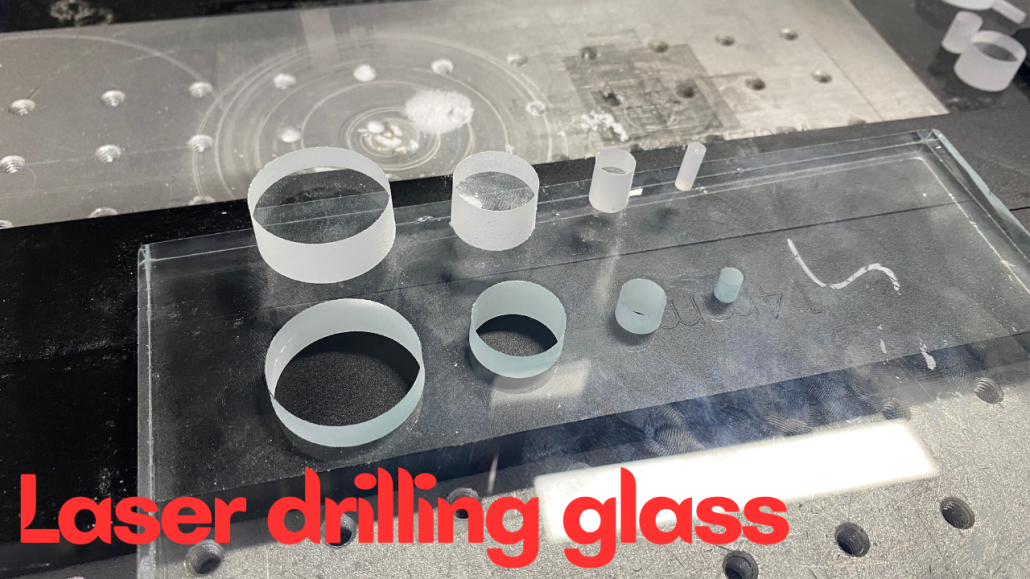

🪞 Machine de sablage au laser pour miroir : La solution ultime pour le verre givré, le décapage de revêtements et le perçage

La machine de sablage au laser pour miroir révolutionne le traitement des surfaces en verre, en intégrant le sablage laser, le décapage de peinture et le perçage dans un seul et même équipement. Obtenez des finis givrés impeccables, éliminez les revêtements avec efficacité et percez avec une précision laser – tout cela sans le désordre des méthodes traditionnelles.

🔥 Comment ça fonctionne ?

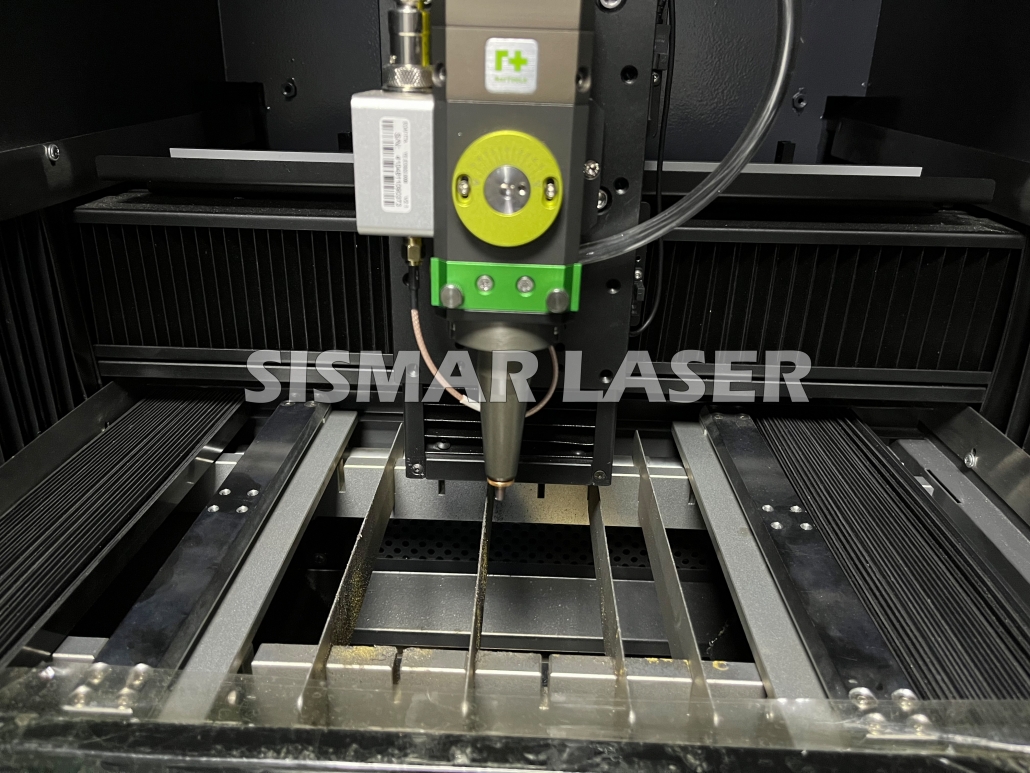

Notre machine de sablage au laser pour miroir utilise des faisceaux laser focalisés pour retirer délicatement la peinture ou les revêtements de la surface du verre, créant ainsi des effets givrés homogènes et élégants.

✅ Aucune poussière

✅ Aucun produit chimique

✅ Un traitement écologique et propre

Que vous travailliez sur des miroirs décoratifs ou du verre spécial, vous obtenez un résultat précis et net. De plus, la fonctionnalité de perçage laser permet de réaliser des trous ou motifs avec une précision extrême, offrant une flexibilité supplémentaire pour des designs complexes.

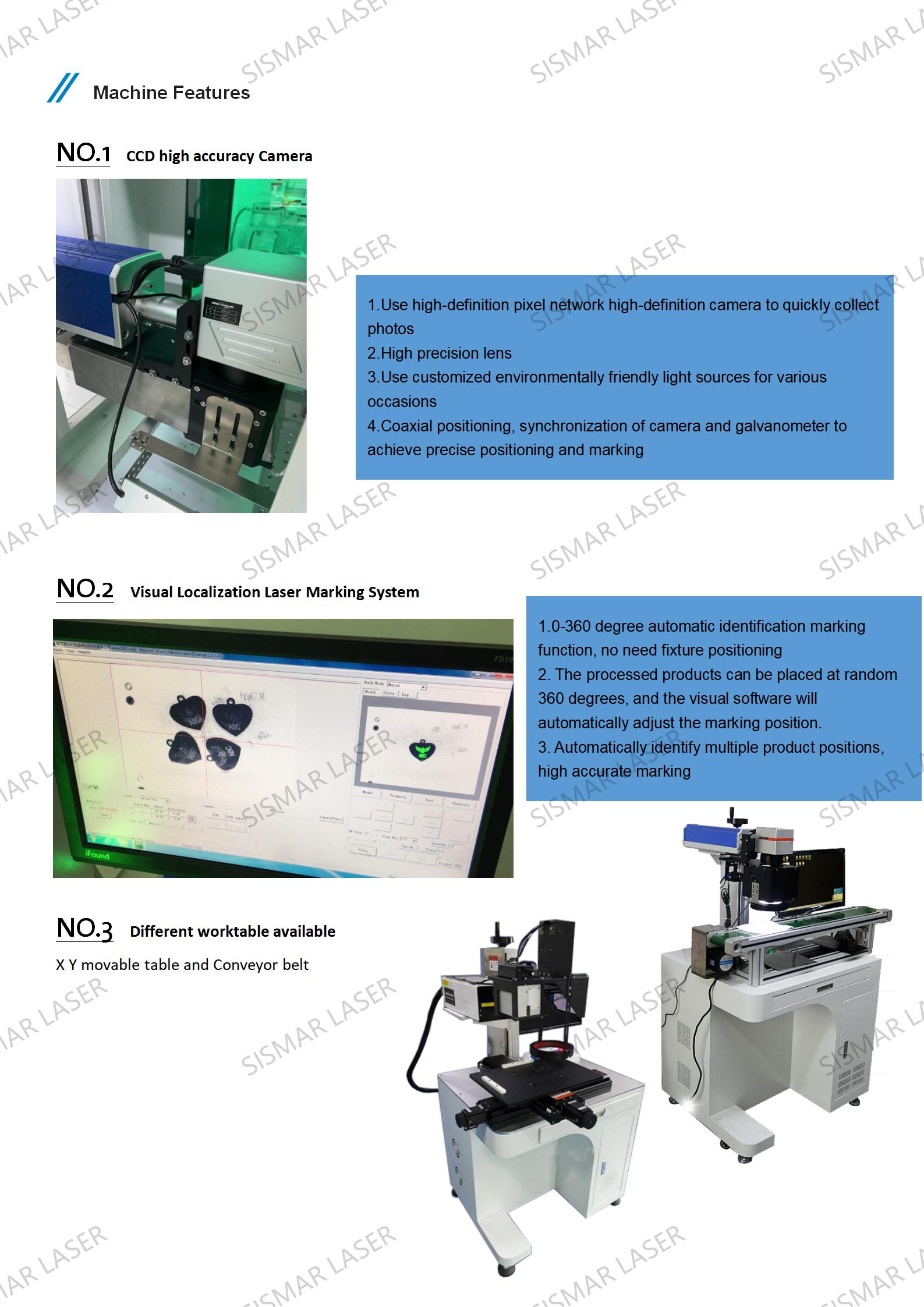

⚙️ Caractéristiques clés

🔹 🛠️ Tout-en-un : Combine sablage laser, décapage laser et perçage laser en une seule machine.

🔹 🎯 Précision laser : Créez des finitions givrées parfaites et des perçages ultra-précis grâce à la technologie avancée du perçage laser pour miroirs.

🔹 🌱 Écologique & efficace : Sans poussière, sans produits chimiques, un traitement propre et durable.

🔹 ⚡ Production rapide : Conçu pour les grands volumes, avec un flux de travail optimisé et un temps d’arrêt minimal.

🔹 🛡️ Faible entretien : Matériel robuste et durable, nécessitant peu de maintenance pour une performance fiable sur le long terme.

📊 Paramètres techniques de la machine de sablage au laser pour miroir

| 🔍 Nom | Machine de gravure et de perçage laser pour verre miroir |

|---|---|

| 🔦 Puissance laser | 120W / 200W |

| 🔗 Type de laser | Générateur laser à fibre métallique anti-reflet haute puissance |

| 📏 Taille maximale des matériaux | 1,5m x 3m (personnalisable) |

| 🪞 Matériaux compatibles | Miroir en argent, miroir en aluminium, miroir sans cuivre écologique, miroir en résine, etc. |

| 📐 Précision de traitement laser | 1 fil (0,01 mm) |

| ⚡ Puissance de l’équipement | 4500W |

| 🚀 Vitesse de mouvement | 0-40m/min |

| 📏 Épaisseur traitable | 1-50 mm |

| 💧 Refroidissement | Système de refroidissement par eau à température constante |

| 📍 Fixation | Fixation à quatre stations en alliage d’aluminium |

| ⚖️ Poids | 1500 kg |

🎯 Pourquoi choisir cette machine ?

Que vous ayez besoin de finitions givrées pour des miroirs intelligents, du verre décoratif, ou d’un perçage ultra-précis pour vos conceptions, la machine de sablage au laser pour miroir est la solution fiable, rapide et écologique qui s’adapte à tous vos besoins en traitement du verre.

🔑 Mots-clés SEO :

✅ Machine de sablage au laser pour miroir

✅ Décapage laser de peinture sur miroir

✅ Machine de perçage laser pour miroir

✅ Machine de perçage laser pour verre

✅ Finitions en verre givré

✅ Traitement écologique du verre

✅ Traitement laser pour miroir intelligent

🌟 Investissez dans la performance et la précision ! Contactez-nous dès maintenant pour en savoir plus. 🚀

🚀 Pourquoi le sablage laser pour miroirs intelligents est une révolution pour votre entreprise de verre

Encore coincé dans le passé avec le sablage traditionnel ou la peinture givrée ? Il est temps de passer à la vitesse supérieure. Le sablage laser pour miroirs intelligents transforme totalement le traitement du verre, offrant des avantages imbattables par rapport aux méthodes obsolètes.

Adopter le sablage laser ne vous fera pas seulement économiser de l’argent, mais boostera également votre productivité et fera briller vos produits sur le marché.

💰 1. Réduisez vos coûts : Plus besoin de consommables

🔸 Sablage traditionnel : Remplacement constant d’abrasifs coûteux (poudre de diamant, sable, grenailles)… Une dépense qui ne finit jamais.

🔸 Sablage laser : Zéro consommable ! Un investissement unique qui continue à rapporter. Moins de dépenses en matériaux, moins de déchets… et plus de profit dans votre poche.

🧹 2. Un atelier propre : Fini la poussière et le désordre

🔸 Méthodes classiques : Un nuage de poussière envahit votre espace, nécessitant un nettoyage constant et des équipements de protection. Risques pour la santé de votre équipe, perte de temps, inefficacité…

🔸 Sablage laser : Zéro poussière, zéro débris. Un processus propre et sans contact – juste un faisceau laser précis qui fait tout le travail. Un environnement plus sûr, plus sain, et une équipe reconnaissante !

🎯 3. Une précision inégalée : Parfait du premier coup

🔸 Sablage traditionnel : Vous voulez une texture homogène ? Bonne chance… Résultats irréguliers, finition souvent inégale.

🔸 Sablage laser : Précision laser absolue, permettant de créer des motifs complexes, des textures détaillées et des effets spectaculaires sur le verre. Aucune erreur, aucun rebut, juste la perfection.

🔥 4. Des résultats durables et résistants

🔸 Peinture givrée : Belle au début, mais s’efface rapidement. Vos clients devront la retoucher, ce qui impacte la satisfaction.

🔸 Sablage laser : La finition laser est permanente. Elle ne s’use pas, ne s’écaille pas, et reste impeccable pendant des années. Résultat ? Des clients conquis par une qualité inégalée.

⚡ 5. Gagnez du temps et de l’argent : Automatisation = efficacité maximale

🔸 Sablage traditionnel : Travail manuel, réglages constants, lenteur… Bref, inefficace et coûteux.

🔸 Sablage laser : Automatisé, donc production accélérée, coûts de main-d’œuvre réduits et rendement amélioré. Plus de travail en moins de temps, sans compromettre la qualité.

🔄 6. Polyvalence totale : Adapté à tous types de verre

🔸 Sablage traditionnel : Ne fonctionne pas avec tous les types de verre, et les résultats varient selon les matériaux.

🔸 Sablage laser : Compatible avec tous les types de verre, du miroir intelligent au verre décoratif, en passant par les pièces artistiques et objets ménagers. Flexible et prêt à relever tous les défis créatifs.

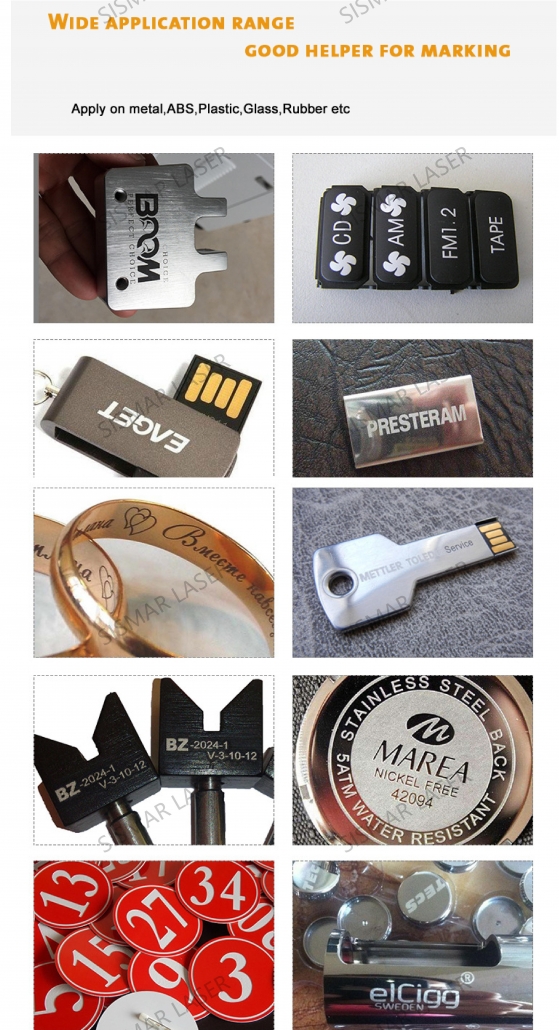

🚀 Applications de la Machine de Sablage Laser pour Miroirs

La Machine de Sablage Laser pour Miroirs est un outil polyvalent, utilisé dans divers secteurs pour offrir des finitions précises, propres et durables. Voici comment elle peut révolutionner votre production :

🪞 1. Fabrication de miroirs intelligents

✨ Créez des effets givrés ultra-précis sur les miroirs intelligents.

✨ Ajoutez des motifs et designs personnalisés sans utiliser de films ou de revêtements.

✨ Idéal pour les fabricants de miroirs connectés recherchant une précision optimale.

🏢 2. Transformation du verre architectural

🏗️ Parfait pour concevoir des verres décoratifs et givrés destinés à l’architecture moderne.

🏗️ Idéal pour les fenêtres, cloisons, façades et autres éléments structuraux.

🏗️ Apportez une touche unique et élégante aux projets architecturaux.

🎨 3. Personnalisation d’art en verre

🖌️ Un atout majeur pour les artistes verriers souhaitant réaliser des gravures fines et détaillées.

🖌️ Permet de créer des designs complexes et personnalisés sur des œuvres d’art en verre.

🖌️ Un outil révolutionnaire pour repousser les limites de la créativité.

🚗 4. Personnalisation du verre automobile

🚘 Ajoutez des logos, motifs et designs uniques aux vitres et pièces en verre automobile.

🚘 Une solution idéale pour les constructeurs et les ateliers de personnalisation.

🚘 Obtenez des résultats nets et précis, sans risque de détérioration.

📢 5. Signalétique et branding sur verre

🏆 Gravez des logos, noms et designs pour créer des enseignes en verre personnalisées.

🏆 Idéal pour la fabrication de plaques d’entreprise, trophées et supports promotionnels.

🏆 Un rendu haut de gamme, parfait pour marquer les esprits.

🛠️ 6. Restauration et réparation de miroirs

🔄 Restaurez les miroirs anciens en éliminant rayures, taches et anciens revêtements.

🔄 Donnez une seconde vie aux miroirs endommagés grâce à un traitement précis.

🔄 Résultat : un miroir lisse, propre et comme neuf.

🏡 7. Gravure sur articles ménagers en verre

🎁 Appliquez des designs personnalisés sur des objets en verre du quotidien.

🎁 Idéal pour la personnalisation de verrerie, décorations et cadeaux uniques.

🎁 Ajoutez une touche élégante et originale à n’importe quel objet en verre.

⭐ Pourquoi choisir la Machine de Sablage Laser pour Miroirs ?

✅ Précision absolue : Des motifs et finitions réalisés avec une exactitude parfaite.

✅ Écologique : Aucune poussière, aucun produit chimique – un traitement propre et efficace.

✅ Durabilité exceptionnelle : Contrairement aux finitions peintes qui peuvent s’effacer ou s’écailler, les motifs laser restent intacts dans le temps.

💡 Passez à la technologie du futur et offrez à vos clients des finitions haut de gamme avec la Machine de Sablage Laser pour Miroirs !

❓ Foire Aux Questions (FAQ) – Machine de Sablage Laser pour Miroirs

1️⃣ À quoi sert une Machine de Sablage Laser pour Miroirs ?

La Machine de Sablage Laser pour Miroirs est utilisée pour créer des finitions miroir, sabler des surfaces et enlever la peinture sur le métal, le verre et d’autres matériaux. Elle permet d’obtenir des surfaces lisses et brillantes tout en supprimant efficacement les revêtements comme la peinture, la rouille et les oxydes.

2️⃣ Cette machine peut-elle enlever la peinture sur tous types de surfaces ?

✅ Oui ! Elle est ultra-performante pour décaper la peinture sur divers matériaux : métal, verre, plastique, pierre…

✅ Idéale pour le nettoyage des surfaces, le décapage et la restauration sans abîmer le support.

3️⃣ Quels types de matériaux peuvent être traités avec cette machine ?

Cette machine fonctionne sur une large gamme de matériaux :

🔹 Métal

🔹 Verre

🔹 Plastique

🔹 Pierre

🔹 Céramique

📌 Parfait pour les industries automobile, construction, restauration d’art et travail du métal.

4️⃣ Comment la machine crée-t-elle une finition miroir ?

💡 Grâce à sa technologie laser avancée, la machine réalise un sablage ultra-précis, produisant une finition lisse et brillante.

📌 En ajustant les paramètres laser, vous pouvez choisir entre un effet brillant ou mat, selon vos besoins.

5️⃣ La machine laisse-t-elle des résidus ou endommage-t-elle la surface ?

❌ Non ! Contrairement aux méthodes traditionnelles, le sablage laser est non abrasif et ne laisse aucun résidu.

✅ Il garantit un traitement propre et sans altération de la surface d’origine.

6️⃣ Quelle est l’efficacité de la machine pour enlever la peinture ?

🚀 Extrêmement efficace ! Elle élimine rapidement la peinture, la rouille et l’oxydation sans détériorer le matériau.

📌 Idéal pour les pièces automobiles, structures métalliques, équipements industriels et machines.

7️⃣ Cette machine est-elle adaptée à une utilisation industrielle ?

✅ Oui ! Conçue pour des projets de grande envergure, elle offre une haute efficacité et une rapidité exceptionnelle.

📌 Idéale pour les secteurs automobile, construction, fabrication et restauration artistique.

8️⃣ Comment fonctionne le processus de décapage de peinture ?

💡 La machine utilise la technologie d’ablation laser, où le faisceau laser désintègre la peinture ou le revêtement.

❌ Aucun produit chimique, aucun abrasif – un procédé propre et écologique.

9️⃣ La machine est-elle facile à utiliser ?

✅ Oui ! Son interface intuitive permet de régler facilement :

🔹 La puissance du laser

🔹 La vitesse de traitement

🔹 La fréquence du faisceau

📌 Même un débutant peut la prendre en main rapidement.

🔟 Quel entretien est nécessaire ?

📌 Entretien minimal ! Il suffit de :

🔹 Nettoyer régulièrement la lentille laser 🔍

🔹 Vérifier le système laser pour une performance optimale ⚙️

🔹 Travailler dans un espace bien ventilé 🌬️

1️⃣1️⃣ Quelle est la durée de vie de la machine ?

⚡ Longévité exceptionnelle ! Avec un bon entretien, la machine assure des années de performances fiables.

1️⃣2️⃣ Quelle est la consommation électrique de la machine ?

⚡ La consommation dépend du modèle et du matériau traité.

📌 Économique par rapport aux méthodes abrasives traditionnelles, réduisant les coûts énergétiques.

1️⃣3️⃣ La machine peut-elle traiter des designs complexes et des zones détaillées ?

✅ Oui ! Elle permet un contrôle précis du laser pour des gravures fines et des motifs complexes.

📌 Parfaite pour des décors détaillés, du sablage artistique et des gravures minutieuses.

1️⃣4️⃣ Cette machine est-elle écologique ?

🌱 Absolument ! Contrairement au sablage traditionnel, elle ne nécessite aucun produit chimique ni abrasif, et réduit les déchets.

📌 Une solution propre et durable pour un environnement plus sain.

💡 Passez à la technologie laser et révolutionnez vos traitements de surface avec la Machine de Sablage Laser pour Miroirs ! 🚀

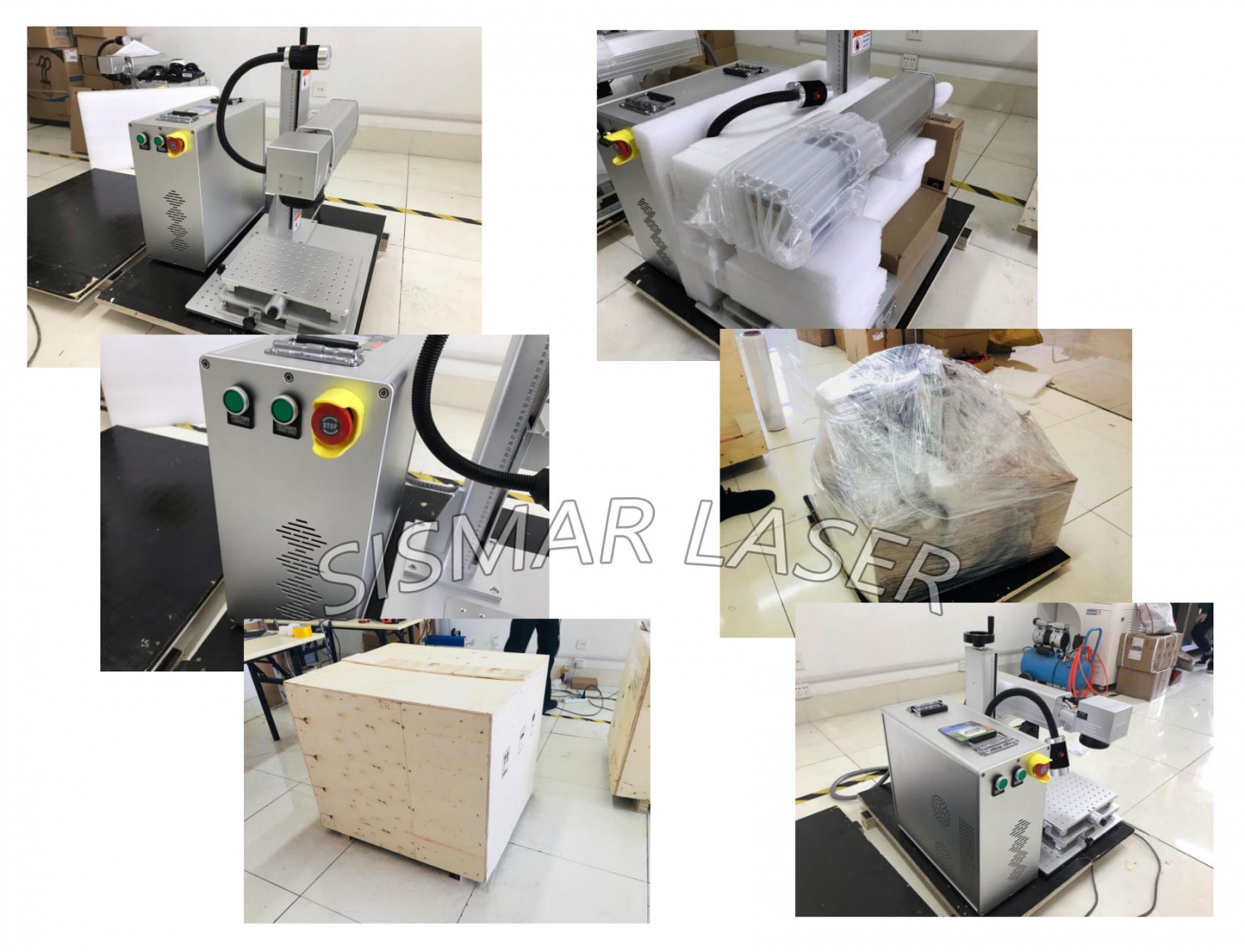

Machine de Marquage Laser et de Gravure sur Verre Sablé

Demander un devis pour une machine de marquage laser à fibre

SISMAR LASER propose des machines laser à fibre et d’autres solutions pour de nombreuses applications industrielles. Nos solutions peuvent être utilisées pour améliorer votre système de marquage laser existant ou comme un excellent choix pour votre première machine laser.

Demandez un devis pour une machine de marquage laser à fibre de haute qualité qui dépasse vos attentes. Vous pouvez également planifier une démonstration pour voir comment fonctionne le marquage laser à fibre.

Bienvenue chez SISMAR Laser. Nous sommes très heureux de répondre à toutes vos questions concernant nos machines de marquage/coupe laser à fibre.