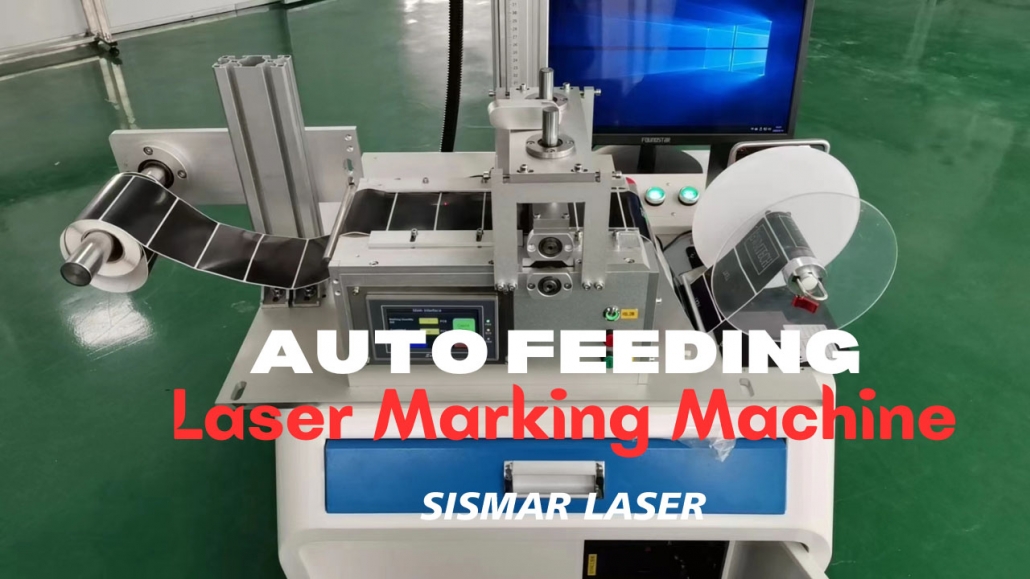

Part-Feeding laser marking machine

/0 Comments/in Products /by linda

Fiber Laser Marking Machine with Automatic

Precision Meets Automation: The Future of Plate Marking

Automatic Laser Plate Marker also is called PART-FEEDING SYSTEMS laser marking machine.

This fiber laser marking system is designed for automatically marking on metal tags and plates at least .025″ thick.

Reduce laser marking time and increase productivity with the part-feeding systems. These systems move parts into your marking machine’s marking field with precision, ensuring they are in the right place for marking. Certain feeders can be loaded while other parts are being marked, minimizing the downtime between cycles.

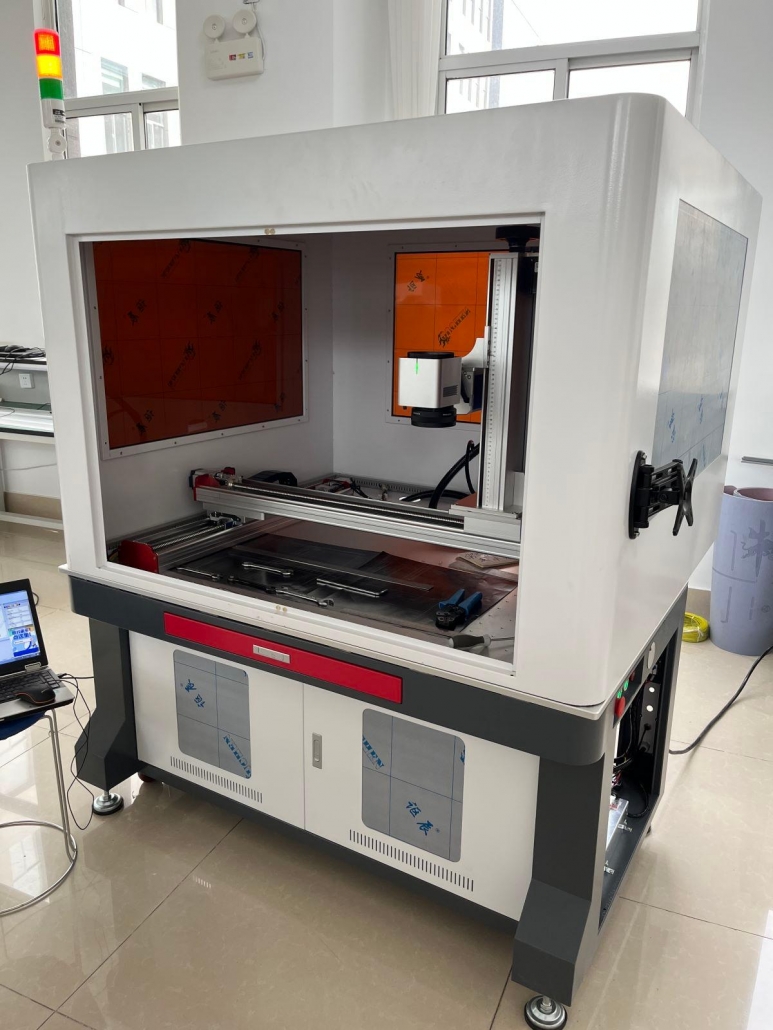

Photos of Automatic Laser Plate Marker

Transform Your Metal Tag Marking Process with Unmatched Efficiency ⚙️

Streamline Production and Boost Productivity with our cutting-edge Fiber Laser Marking System. Specifically engineered for metal tags and plates with a thickness of at least .025″, this system is designed to save time and increase throughput like never before.

1️⃣ How It Works: Seamless Automation 🔄

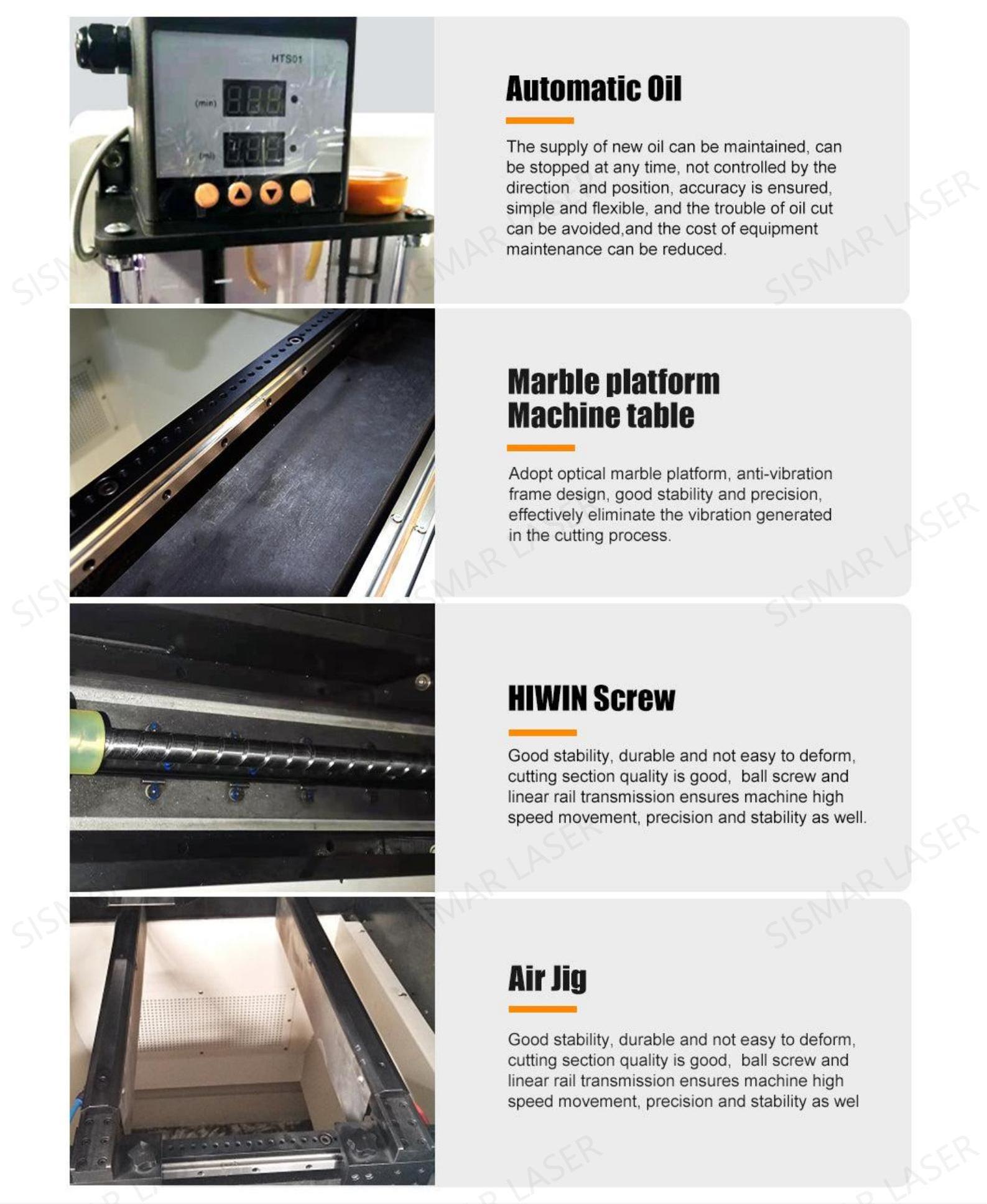

- Load, Mark, Repeat: Simply load a roll label or metal foil onto the indexing table (rotary dial plate), and let the machine do the rest.

- Automatic Feeding: The feeding mechanism takes each plate into the lasing chamber for precise marking.

- Continuous Operation: Once the marking process is complete, the system automatically collects the roll label or foil back onto the rotary dial, ready for the next part to be marked.

2️⃣ Increase Efficiency & Reduce Downtime 💡

Reduce laser marking time and enhance productivity with our part-feeding systems. These innovative systems precisely position your parts in the marking field, ensuring each part is perfectly placed for marking. Load parts while others are being marked, minimizing downtime and maximizing throughput!

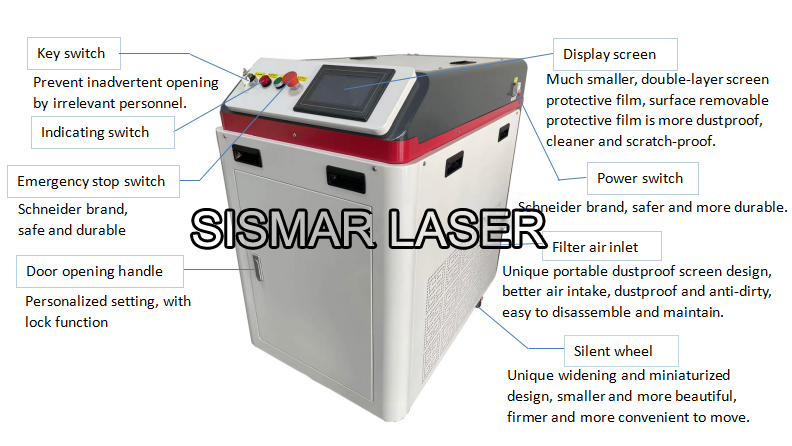

3️⃣ Flexible Software for Every Need 💻

- Operate the system as a network device or as a stand-alone unit.

- Receive data from any source, making the system adaptable to your unique requirements.

- The full-featured plate production software ensures smooth operation every time.

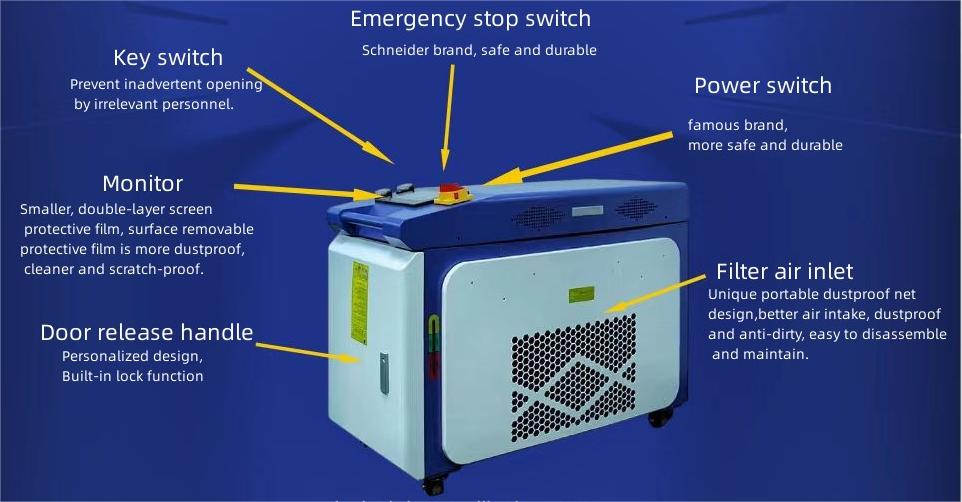

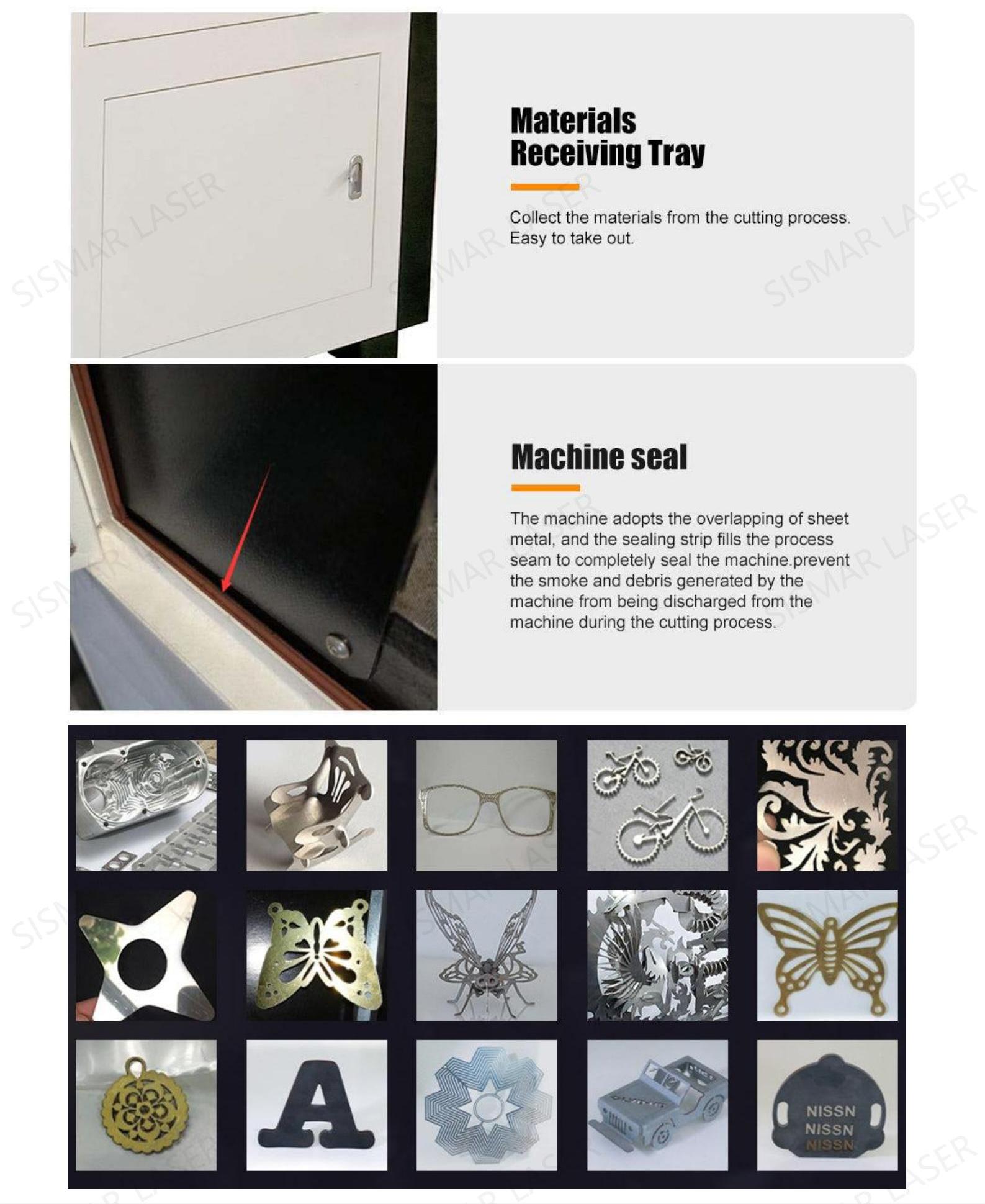

4️⃣ Safety First: Laser-Safe Operation 🛡️

Your safety is our priority. This system includes:

- A protective cover and enclosure to prevent exposure to harmful laser radiation.

- A laser-safe window that lets the operator safely view the inside of the chamber while the tags are being marked.

5️⃣ Clean and Safe Work Environment 🌬️

Say goodbye to fumes! The system comes equipped with a fume extractor to efficiently vent any fumes, ensuring a cleaner, safer work area.

6️⃣ Why Choose This System?

- Maximized productivity with continuous, automated operation.

- Safe and efficient design with advanced safety features.

- Versatile software for easy integration into your existing processes.

- Environmentally-friendly with integrated fume extraction.

🔧 Ready to Take Your Metal Marking to the Next Level?

Upgrade to our Fiber Laser Marking System today and experience precision, speed, and reliability like never before.

Item | SL-F30/50/60 | |

Ø Laser parameters | optical maser | JPT/Raycus |

Laser wavelength | 1064nm | |

Average output power | 30W/50W/60W | |

Whether or not to bring the light isolation | bring | |

Modulation frequency range | 20kHz~80kHz | |

Ø Galvo parameters | Maximum speed | 7000mm/s |

resolution | 0.001mm | |

Repositioning precision | ±0.003mm | |

Ø Optical output characteristics

| Marking area | 110*110mm |

Minimum line width | 0.01mm | |

Minimum height of characters | 0.2mm | |

Ø Cooling system | Cooling way | Air cooling |

Ø System properties | Laser power supply | 0.5KW/AC220V/50Hz~60Hz (optional 110V) |

Environmental requirements | 0 ~ 35 ° C, 90% or humidity | |

The Power of the Automatic Scroll Device for Laser Marking Machines 🔄

The automatic scroll device of the laser marking machine is a game-changer for industries looking to ramp up their metal tag and plate production. Whether you’re looking for continuous production, mass production, or integration with automated systems, this device is built to boost efficiency and cut costs in your manufacturing process.

1️⃣ Continuous Production of Metal Tags & Plates 🔧

With the automatic scroll device, your production line can seamlessly feed metal tags or plates into the marking area without any interruptions. This leads to a more efficient and continuous production process, reducing idle time and keeping your machine running at full capacity.

2️⃣ Large-Scale Production Made Easy 📈

For those needing to produce metal tags and plates in large quantities, the automatic scroll device is the perfect solution. It allows you to automate the entire production cycle, making it easier to scale operations and achieve mass production without sacrificing precision or quality.

3️⃣ Integration with Automated Production Lines 🤖

Take your production to the next level by integrating the automatic scroll device with your existing automated assembly lines or production lines. This integration creates a fully automated production environment, allowing for streamlined operations and higher throughput.

4️⃣ Save on Labor Costs 💸

The automatic scroll device minimizes the need for manual intervention, effectively reducing labor costs while ensuring consistent production quality. It’s a smart, cost-effective choice for companies looking to boost profitability and efficiency.

5️⃣ Ideal for a Variety of Industrial Applications 🌍

The automatic scroll device is versatile and suitable for various industrial and production environments that demand:

- Continuous operation

- High-volume production

- Automated integration

Why Choose the Automatic Scroll Device?

- Maximized efficiency with continuous feeding.

- Higher production capacity for large-scale runs.

- Seamless integration with automated production systems.

- Reduced labor costs and improved consistency.

🔧 Ready to Supercharge Your Production Process?

Implement the automatic scroll device with your laser marking machine today and experience the future of efficient, large-scale production.

Automatic Laser Plate Marker FAQ 🤖

1️⃣ What is an Automatic Laser Plate Marker?

An Automatic Laser Plate Marker is a cutting-edge machine designed to mark or engrave metal plates and tags with high precision. It automates the marking process, allowing continuous, high-speed production with minimal manual intervention.

2️⃣ What materials can be marked with this system?

The Automatic Laser Plate Marker is primarily used for marking metal plates and tags. It is ideal for metals like stainless steel, aluminum, brass, and copper, providing clear and durable marks that last.

3️⃣ How does the automatic feeding system work?

The system features an automatic scroll device that feeds metal plates into the marking chamber automatically. This continuous feeding process ensures minimal downtime and increased production efficiency by keeping the machine running without manual intervention.

4️⃣ Can the system be integrated with other production lines?

Yes! The Automatic Laser Plate Marker can be seamlessly integrated with existing automated assembly lines or other production systems, enabling full automation and enhanced efficiency in high-volume production environments.

5️⃣ What type of marking does the laser produce?

The laser marking process can produce text, serial numbers, logos, barcodes, and QR codes on the metal plates. The marks are highly precise, durable, and resistant to wear, ensuring that they remain legible over time.

6️⃣ Is the system easy to operate?

Yes! The automatic laser plate marker is designed for user-friendly operation, featuring intuitive software and easy-to-use controls. Once set up, it requires minimal supervision and can run continuously with minimal intervention.

7️⃣ How do I ensure safety while using the laser marker?

The system comes equipped with safety enclosures and protective covers to prevent exposure to laser radiation. Laser-safe windows allow operators to monitor the process without compromising safety. Additionally, there are emergency stop features for added security.

8️⃣ What is the production capacity of the system?

The production capacity depends on the size of the plates and the marking complexity. However, the automatic feeding system allows for high-volume production, handling large batches efficiently with consistent quality and minimal downtime between cycles.

9️⃣ How does the system handle fume extraction?

The system is equipped with an integrated fume extractor to remove any fumes or particles produced during the marking process, ensuring a cleaner and safer work environment.

🔟 What industries can benefit from the Automatic Laser Plate Marker?

This system is ideal for industries such as:

- Automotive (for marking parts and components)

- Aerospace (for precise part identification)

- Manufacturing (for continuous production of metal tags and plates)

- Electronics (for marking serial numbers or barcodes)

- Medical Devices (for product traceability and compliance)

💡 Need More Information?

Feel free to reach out for any additional questions or to schedule a demo of the Automatic Laser Plate Marker!

Laser Marking Video

Request a Quote for a Fiber Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.