Author Archive for: linda

About linda

This author has yet to write their bio.Meanwhile lets just say that we are proud linda contributed a whooping 427 entries.

Entries by linda

Laser application on Smart mirror industry

May 7, 2024 /0 Comments/in Blog /by lindaComparision of Laser glass drilling machine Green Laser VS M8 fiber laser

April 28, 2024 /0 Comments/in Blog /by lindaComparison of three processes for glass cutting/drilling Machine

April 28, 2024 /0 Comments/in Blog /by linda3D Crystal Laser Engraving Machine

April 9, 2024 /0 Comments/in Products /by linda

Affordable, Easy, and Powerful – Your UV Crystal Engraving Solution

Turn Crystals into Memories – Fast & Easy

Want to start a small business or create unique personalized gifts? Our UV 3D Crystal Laser Engraving Machine makes it simple. Engrave stunning 3D images inside crystals or precise designs on the surface—all with minimal heat, high detail, and no complicated setup.

It works on crystal, glass, and acrylic, handles engraving up to 60 × 60 × 70 mm, and supports DXF, CAD, BMP, JPG files. Whether it’s gifts, awards, or decorative art, you can create professional, emotional keepsakes without breaking the bank.

Start small. Impress big. Make memories people will never forget.

3D crystal UV Laser Marking Machine Photo

✨ Start Your Crystal Business with the UV 3D Laser Engraving Machine

Looking to start your own personalized gift or crystal engraving business? The UV 3D Laser Engraving Machine is perfect for beginners—affordable, easy to operate, and capable of producing stunning 3D crystal engravings and precise surface engravings.

🌟 Why UV Laser is Perfect for Starters

-

Cost-Effective – Lower investment compared to high-power green lasers, ideal for small startups.

-

Fine Detail & Precision – Short wavelength UV laser allows sharp, intricate designs both inside the crystal and on its surface.

-

Minimal Heat Damage – Clean engravings without cracking or discoloring delicate materials.

-

Low Maintenance & Easy Operation – Air-cooled, user-friendly software, automatic centering.

-

Versatile Applications – Works on crystal, glass, acrylic, and other transparent or hard materials. Perfect for personalized gifts, awards, and decorative items.

💡 Available Power Options for Different Needs

| Power | Ideal Use | Material |

|---|---|---|

| 5W | Small, delicate engravings | Glass, soft acrylic |

| 10W | Versatile for most designs | Crystal & glass |

| 15W | Deeper 3D engravings with enhanced depth | Crystal |

🏆 UV Laser Crystal Engraving Parameters

3D Subsurface Engraving (Inside Crystal):

-

Engraving Size: 60 × 60 × 70 mm

-

Laser Type: Air-cooled semiconductor UV laser

-

Laser Wavelength: 355 nm

-

Power: 5W / 10W / 15W

-

Engraving Speed: Up to 300,000 dots/min

-

Resolution: High-precision dot matrix

-

Data Formats Supported: DXF, CAD, BMP, JPG

-

Operation: Automatic center function, easy placement, shockproof protection

-

Material Compatibility: Optical crystal, glass, acrylic

Surface Engraving (On Crystal, Glass, or Acrylic):

-

Engraving Depth: Adjustable (surface to several mm)

-

Material Compatibility: Crystal, glass, acrylic, plastic, coated surfaces

-

Precision: Sharp, clean lines, minimal heat damage

-

Applications: Logos, text, decorative patterns, personalized surface designs

🛠️ Machine Specifications

| Specification | Details |

|---|---|

| Laser Type | Air-cooled semiconductor UV laser, solid-state |

| Laser Wavelength | 355 nm |

| Laser Power | 5W / 10W / 15W |

| Engraving Size (3D) | 60 × 60 × 70 mm |

| Engraving Speed | Up to 300,000 dots/min |

| Resolution | High-precision dot matrix |

| Data Formats Supported | DXF, CAD, BMP, JPG |

| Control System | User-friendly software, automatic centering |

| Cooling | Air-cooled, low maintenance |

| Design | Sealed, shockproof, low-noise operation |

| Material Compatibility | Crystal, glass, acrylic, plastic, coated surfaces |

| Applications | 3D subsurface engraving, surface engraving, logos, text, decorative patterns |

| Operation | Easy crystal placement, automatic centering, shockproof protection |

| Galvanometer Scanning Method | High-speed scanning for fast, precise engraving |

| Weight & Dimensions | [Fill in according to actual machine model] |

🌍 Applications

The UV 3D Laser Engraving Machine is ideal for multiple industries and purposes:

-

Personalized Gifts – Keepsakes, portraits, and custom crystal items 🎁

-

Corporate Awards & Trophies – Logos, company recognition, and plaques 🏅

-

Memorial & Commemorative Pieces – Custom memorial gifts and decorative items 💖

-

Art & Décor – Decorative panels, crystal art, and creative designs 🖼️

-

Hotels & Restaurants – Custom décor, engraved glassware, and gifts

-

Retail & Printing Shops – Personalized products, promotional items

-

Manufacturing & Prototyping – Part marking, product branding, samples

-

Home Use – DIY projects and personalized keepsakes

🎯 Perfect For Beginner Entrepreneurs

Start small, impress big. With the UV 3D Laser Engraving Machine, your startup can create both emotional 3D crystal keepsakes and surface-engraved products, giving you maximum versatility and business potential.

Green Laser vs. UV Laser Crystal Engraving

Looking for the right crystal engraving solution?

Green Laser machines deliver unmatched speed and engraving quality. With high single-pulse energy and fast crack formation, they produce vivid and clear 3D portraits with strong depth, making them the perfect choice for professional workshops and mass production.

On the other hand, UV Laser machines come at a lower cost, making them ideal for startups and beginners who want to enter the crystal engraving business. While UV lasers are slower and less vivid in 3D effects, they provide an affordable entry-level solution.

✅ Choose Green Laser for speed, clarity, and premium results.

✅ Choose UV Laser for affordability and a smooth business start.

| Comparison | Green Laser | UV Laser |

|---|---|---|

| Speed | High single-pulse energy, fast crack formation, much higher engraving speed. Perfect for mass production. | Lower single-pulse energy, slower crack formation, lower overall speed. Not suitable for high-volume production. |

| Engraving Quality | Produces full and uniform cracks, delivering clear and vivid 3D portraits with strong depth. Excellent for large-scale patterns. | Creates very fine cracks, suitable for micro-details, but less 3D effect and weaker depth on portraits or big designs. |

| Cost | Higher equipment investment, but provides faster ROI through high efficiency and premium quality. | Lower equipment cost, more affordable for startups and beginners entering the crystal engraving business. |

✅ Summary

-

Green Laser → Faster speed + Superior 3D effect → Best choice for professional workshops & mass production.

-

UV Laser → Lower cost + Entry-level solution → Good choice for startups and beginners.

❓ UV 3D Laser Engraving Machine FAQ

Q1: Who is this machine suitable for?

A: This machine is ideal for beginners, small businesses, startups, and hobbyists who want to create personalized gifts, awards, or decorative crystal items. Its low investment, easy operation, and high precision make it perfect for first-time users.

Q2: What materials can the UV laser engraver work with?

A: It works on crystal, glass, acrylic, plastic, and coated surfaces. It supports both 3D subsurface engraving inside crystal and surface engraving on the material.

Q3: What are the engraving size limits?

A: The maximum 3D engraving size is 60 × 60 × 70 mm. Surface engraving can vary depending on material and design.

Q4: What power options are available?

A: The machine comes in 5W, 10W, and 15W.

-

5W: For delicate, fine details on glass or acrylic.

-

10W: Versatile, suitable for most crystal and glass projects.

-

15W: For deeper, more detailed 3D engravings with enhanced contrast.

Q5: What file formats does it support?

A: Supports DXF, CAD, BMP, JPG, making it compatible with most design software.

Q6: How fast is the engraving process?

A: The high-speed galvanometer scanning allows up to 300,000 dots per minute, making production fast and efficient.

Q7: Does it require special maintenance?

A: No. The machine uses air-cooled semiconductor UV laser technology, is low maintenance, shockproof, and designed for long-term, stable use.

Q8: Can it engrave both 2D and 3D designs?

A: Yes. The machine can do 3D subsurface engraving inside crystal and 2D surface engraving on crystal, glass, acrylic, or plastic.

Q9: Is it safe and eco-friendly?

A: Yes. It’s sealed, low-noise, air-cooled, and doesn’t require compressors or produce high-power fan noise. Minimal environmental impact.

Q10: What are the main applications of this machine?

A: Perfect for personalized gifts, corporate awards, memorial pieces, art & décor, retail products, promotional items, and small-scale manufacturing.

Videos of 3D Subsurface Laser Engraving Machine For Crystal & Glass

Request a Quote for a 3D Crystal Laser Inner Engraving Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

More 3D Crystal Laser inner engraving machine

3D Subsurface Laser Engraving Machine For Crystal & Glass

April 9, 2024 /0 Comments/in Blog /by lindaPart-Feeding laser marking machine

April 2, 2024 /0 Comments/in Products /by linda

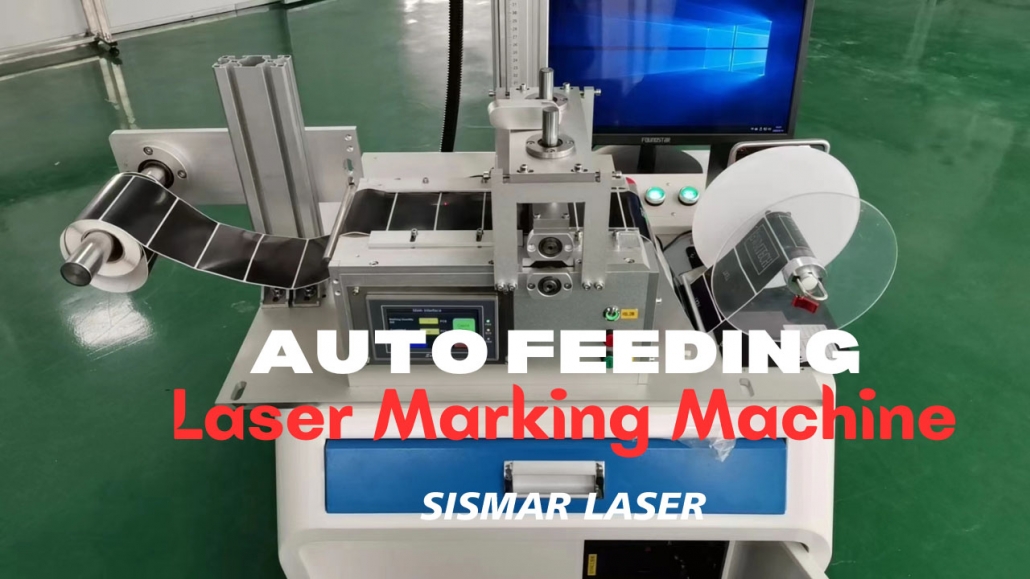

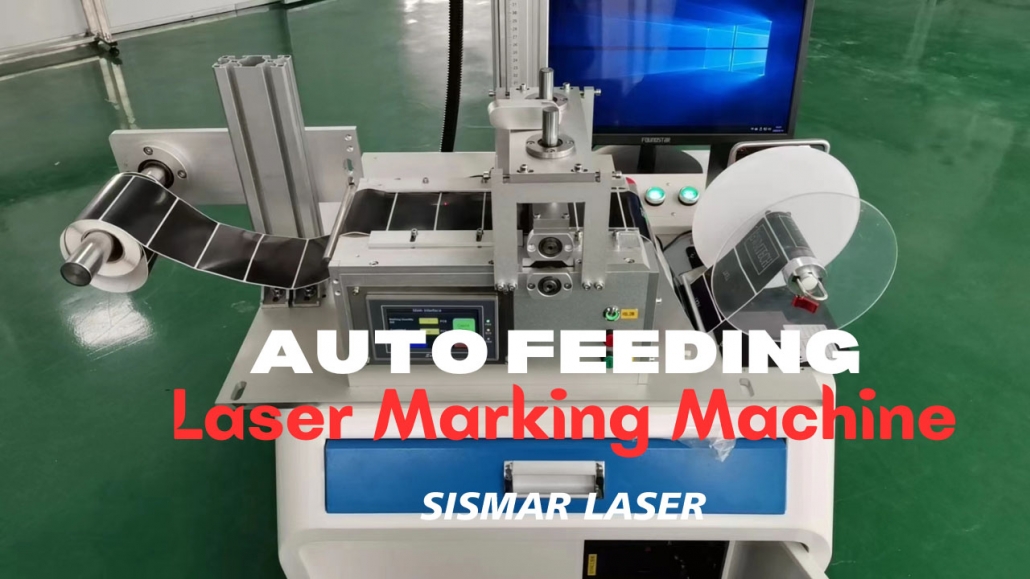

Fiber Laser Marking Machine with Automatic

Precision Meets Automation: The Future of Plate Marking

Automatic Laser Plate Marker also is called PART-FEEDING SYSTEMS laser marking machine.

This fiber laser marking system is designed for automatically marking on metal tags and plates at least .025″ thick.

Reduce laser marking time and increase productivity with the part-feeding systems. These systems move parts into your marking machine’s marking field with precision, ensuring they are in the right place for marking. Certain feeders can be loaded while other parts are being marked, minimizing the downtime between cycles.

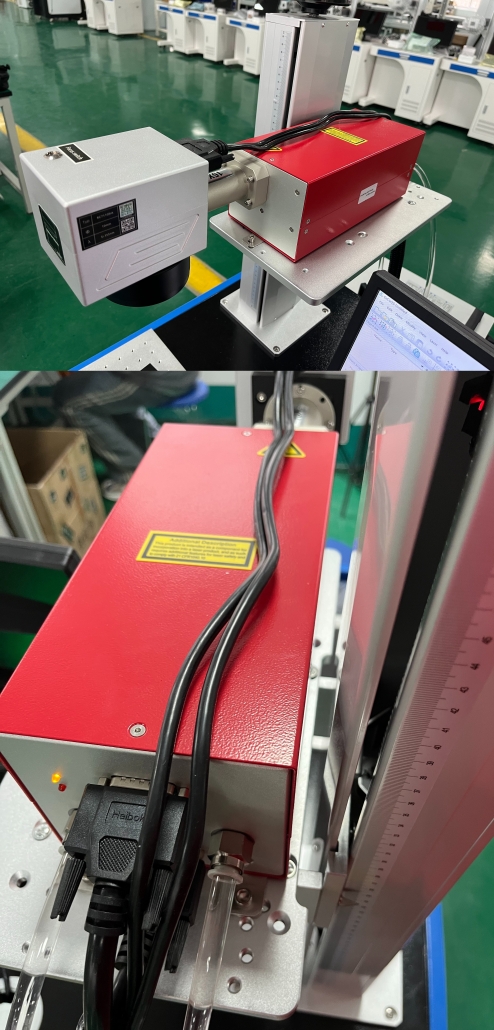

Photos of Automatic Laser Plate Marker

Transform Your Metal Tag Marking Process with Unmatched Efficiency ⚙️

Streamline Production and Boost Productivity with our cutting-edge Fiber Laser Marking System. Specifically engineered for metal tags and plates with a thickness of at least .025″, this system is designed to save time and increase throughput like never before.

1️⃣ How It Works: Seamless Automation 🔄

- Load, Mark, Repeat: Simply load a roll label or metal foil onto the indexing table (rotary dial plate), and let the machine do the rest.

- Automatic Feeding: The feeding mechanism takes each plate into the lasing chamber for precise marking.

- Continuous Operation: Once the marking process is complete, the system automatically collects the roll label or foil back onto the rotary dial, ready for the next part to be marked.

2️⃣ Increase Efficiency & Reduce Downtime 💡

Reduce laser marking time and enhance productivity with our part-feeding systems. These innovative systems precisely position your parts in the marking field, ensuring each part is perfectly placed for marking. Load parts while others are being marked, minimizing downtime and maximizing throughput!

3️⃣ Flexible Software for Every Need 💻

- Operate the system as a network device or as a stand-alone unit.

- Receive data from any source, making the system adaptable to your unique requirements.

- The full-featured plate production software ensures smooth operation every time.

4️⃣ Safety First: Laser-Safe Operation 🛡️

Your safety is our priority. This system includes:

- A protective cover and enclosure to prevent exposure to harmful laser radiation.

- A laser-safe window that lets the operator safely view the inside of the chamber while the tags are being marked.

5️⃣ Clean and Safe Work Environment 🌬️

Say goodbye to fumes! The system comes equipped with a fume extractor to efficiently vent any fumes, ensuring a cleaner, safer work area.

6️⃣ Why Choose This System?

- Maximized productivity with continuous, automated operation.

- Safe and efficient design with advanced safety features.

- Versatile software for easy integration into your existing processes.

- Environmentally-friendly with integrated fume extraction.

🔧 Ready to Take Your Metal Marking to the Next Level?

Upgrade to our Fiber Laser Marking System today and experience precision, speed, and reliability like never before.

|

Item |

SL-F30/50/60 |

|

|

Ø Laser parameters |

optical maser |

JPT/Raycus |

|

Laser wavelength |

1064nm |

|

|

Average output power |

30W/50W/60W |

|

|

Whether or not to bring the light isolation |

bring |

|

|

Modulation frequency range |

20kHz~80kHz |

|

|

Ø Galvo parameters |

Maximum speed |

7000mm/s |

|

resolution |

0.001mm |

|

|

Repositioning precision |

±0.003mm |

|

|

Ø Optical output characteristics

|

Marking area |

110*110mm |

|

Minimum line width |

0.01mm |

|

|

Minimum height of characters |

0.2mm |

|

|

Ø Cooling system |

Cooling way |

Air cooling |

|

Ø System properties |

Laser power supply |

0.5KW/AC220V/50Hz~60Hz (optional 110V) |

|

Environmental requirements |

0 ~ 35 ° C, 90% or humidity |

|

The Power of the Automatic Scroll Device for Laser Marking Machines 🔄

The automatic scroll device of the laser marking machine is a game-changer for industries looking to ramp up their metal tag and plate production. Whether you’re looking for continuous production, mass production, or integration with automated systems, this device is built to boost efficiency and cut costs in your manufacturing process.

1️⃣ Continuous Production of Metal Tags & Plates 🔧

With the automatic scroll device, your production line can seamlessly feed metal tags or plates into the marking area without any interruptions. This leads to a more efficient and continuous production process, reducing idle time and keeping your machine running at full capacity.

2️⃣ Large-Scale Production Made Easy 📈

For those needing to produce metal tags and plates in large quantities, the automatic scroll device is the perfect solution. It allows you to automate the entire production cycle, making it easier to scale operations and achieve mass production without sacrificing precision or quality.

3️⃣ Integration with Automated Production Lines 🤖

Take your production to the next level by integrating the automatic scroll device with your existing automated assembly lines or production lines. This integration creates a fully automated production environment, allowing for streamlined operations and higher throughput.

4️⃣ Save on Labor Costs 💸

The automatic scroll device minimizes the need for manual intervention, effectively reducing labor costs while ensuring consistent production quality. It’s a smart, cost-effective choice for companies looking to boost profitability and efficiency.

5️⃣ Ideal for a Variety of Industrial Applications 🌍

The automatic scroll device is versatile and suitable for various industrial and production environments that demand:

- Continuous operation

- High-volume production

- Automated integration

Why Choose the Automatic Scroll Device?

- Maximized efficiency with continuous feeding.

- Higher production capacity for large-scale runs.

- Seamless integration with automated production systems.

- Reduced labor costs and improved consistency.

🔧 Ready to Supercharge Your Production Process?

Implement the automatic scroll device with your laser marking machine today and experience the future of efficient, large-scale production.

Automatic Laser Plate Marker FAQ 🤖

1️⃣ What is an Automatic Laser Plate Marker?

An Automatic Laser Plate Marker is a cutting-edge machine designed to mark or engrave metal plates and tags with high precision. It automates the marking process, allowing continuous, high-speed production with minimal manual intervention.

2️⃣ What materials can be marked with this system?

The Automatic Laser Plate Marker is primarily used for marking metal plates and tags. It is ideal for metals like stainless steel, aluminum, brass, and copper, providing clear and durable marks that last.

3️⃣ How does the automatic feeding system work?

The system features an automatic scroll device that feeds metal plates into the marking chamber automatically. This continuous feeding process ensures minimal downtime and increased production efficiency by keeping the machine running without manual intervention.

4️⃣ Can the system be integrated with other production lines?

Yes! The Automatic Laser Plate Marker can be seamlessly integrated with existing automated assembly lines or other production systems, enabling full automation and enhanced efficiency in high-volume production environments.

5️⃣ What type of marking does the laser produce?

The laser marking process can produce text, serial numbers, logos, barcodes, and QR codes on the metal plates. The marks are highly precise, durable, and resistant to wear, ensuring that they remain legible over time.

6️⃣ Is the system easy to operate?

Yes! The automatic laser plate marker is designed for user-friendly operation, featuring intuitive software and easy-to-use controls. Once set up, it requires minimal supervision and can run continuously with minimal intervention.

7️⃣ How do I ensure safety while using the laser marker?

The system comes equipped with safety enclosures and protective covers to prevent exposure to laser radiation. Laser-safe windows allow operators to monitor the process without compromising safety. Additionally, there are emergency stop features for added security.

8️⃣ What is the production capacity of the system?

The production capacity depends on the size of the plates and the marking complexity. However, the automatic feeding system allows for high-volume production, handling large batches efficiently with consistent quality and minimal downtime between cycles.

9️⃣ How does the system handle fume extraction?

The system is equipped with an integrated fume extractor to remove any fumes or particles produced during the marking process, ensuring a cleaner and safer work environment.

🔟 What industries can benefit from the Automatic Laser Plate Marker?

This system is ideal for industries such as:

- Automotive (for marking parts and components)

- Aerospace (for precise part identification)

- Manufacturing (for continuous production of metal tags and plates)

- Electronics (for marking serial numbers or barcodes)

- Medical Devices (for product traceability and compliance)

💡 Need More Information?

Feel free to reach out for any additional questions or to schedule a demo of the Automatic Laser Plate Marker!

Laser Marking Video

Request a Quote for a Fiber Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

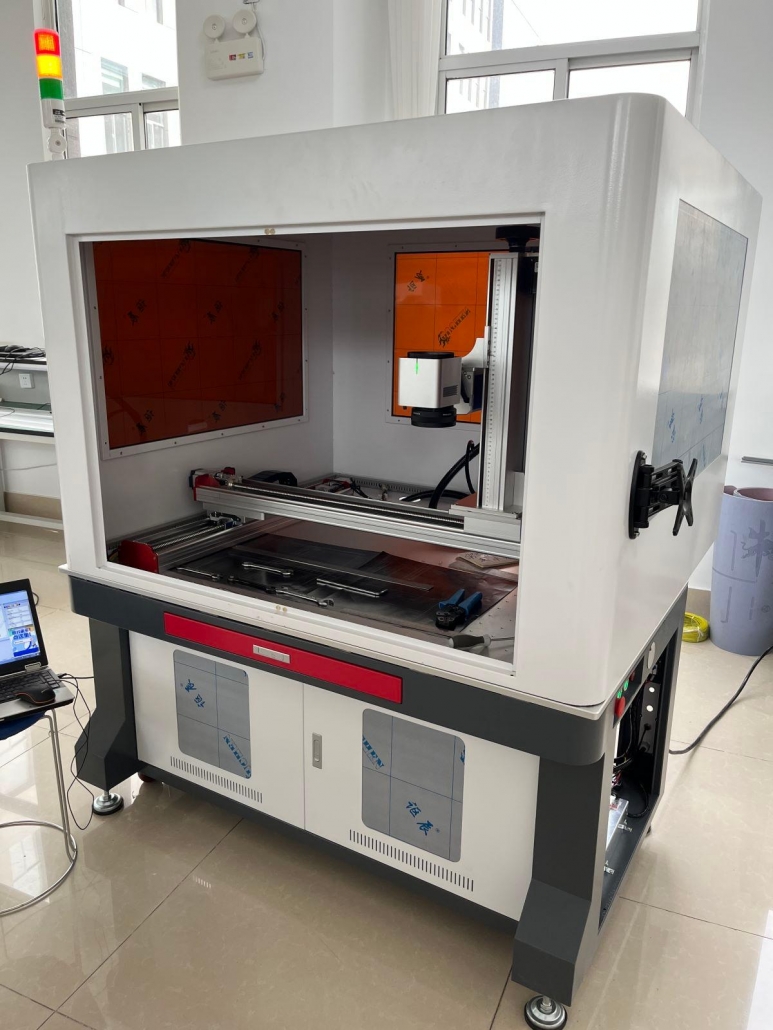

Large format Laser Marking Machine

March 29, 2024 /0 Comments/in Products /by linda

Large format Laser Marking Machine

-

Machine sizes can be customized according to product requirements, ranging from dimensions like 600*500mm to 1300*2500mm, and so on.

-

The Intelligent Continuous Laser Processing System features a follow-up marking function, allowing marking while in operation. This addresses the issue of seam-related problems that were previously unrepairable.

-

The system can accommodate various laser sources, including fiber, CO2, and UV laser sources.

-

Suitable for processing materials such as metal, steel, glass, mirrors, acrylic, wood, paper, and more.

Machine Photos of Large format Laser Marking Machine

Laser Marking Video

Laser sandblasting and drilling machine for mirror glass

March 29, 2024 /0 Comments/in Products /by linda

1300*2500mm Mirror laser sand blasting machine

Large format Mirror Laser Engraving Machine

Mirror Laser Sand Blasting Machine: Fast, Clean, and Precise Surface Treatment

Looking for a mirror laser sand blasting machine? This powerful tool gives you perfect frosted finishes on mirrors and glass while also helping with painting removal—all without the mess.

Here’s why you need it:

- Laser Precision: Get smooth, consistent results every time.

- Fast & Efficient: Perfect for high-volume production.

- Paint Removal: Remove coatings and paint without damage.

- Eco-Friendly: No dust, no chemicals, just clean work.

- Low Maintenance: Designed to last with minimal upkeep.

If you’re looking for a reliable way to create stunning frosted finishes and easily remove paint from glass or mirrors, this is the machine for you.

Machine Photos of Sand Blasting Mirror Laser Machine

Mirror Laser Sand Blasting Machine: The Ultimate Solution for Frosted Glass, Coating Removal, and Drilling

The Mirror Laser Sand Blasting Machine is a game-changer for glass surface treatment, combining mirror laser sand blasting, painting removal, and drilling in one powerful machine. Achieve flawless frosted finishes, remove coatings efficiently, and drill with laser precision—all without the mess of traditional methods.

How It Works:

Our Mirror Laser Sand Blasting Machine uses focused laser beams to gently remove paint or coatings from the glass surface, creating smooth frosted effects. Whether you’re processing mirrors or decorative glass, it ensures precise results—no dust, no chemicals, just clean, eco-friendly processing. The integrated mirror laser drilling machine functionality allows for precise drilling of holes or patterns, and the glass laser drilling machine provides added versatility for intricate designs.

Key Features:

- All-in-One Functionality: Combines mirror laser sand blasting, mirror laser painting removal, and drilling in a single machine.

- Laser Precision: Achieve smooth, consistent frosted finishes and precise pattern drilling with mirror laser drilling machine technology.

- Efficient & Eco-Friendly: No mess, no chemicals—just clean and green processing with the mirror laser sand blasting machine.

- Fast Production: Streamline your workflow for high-volume production with minimal downtime.

- Low Maintenance: Built to last, with minimal upkeep required, providing reliable performance over time.

Parameter of Mirror laser sand blasting machine

|

NAME

|

Mirror Glass Laser Engraving and Drilling Machine

|

|

Laser power

|

120W/200W

|

|

Laser Type

|

Anti-high backfoot power metal fiber laser generator

|

|

Maximum processing material

|

1.5m*3m (customizable)

|

|

Processable light mirror materials

|

Silver mirror, aluminum mirror, environmentally friendly copper-free mirror, resin mirror, etc.

|

|

Laser processing accuracy

|

1 wire (0.01mm)

|

|

Equipment power

|

4500W

|

|

Processing movement speed

|

0-40m/min

|

|

Processing thickness

|

1-50mm

|

|

Cooling method

|

Constant temperature water cooling

|

|

Positioning fixture

|

Aluminum alloy four-station positioning fixture

|

|

Weight(Kg)

|

1500 (kg)

|

Whether you need frosted finishes for smart mirrors, decorative glass, or precise drilling for your designs, the Mirror Laser Sand Blasting Machine offers a reliable, fast, and eco-friendly solution to meet all your glass processing needs.

keywords:

- Mirror Laser Sand Blasting Machine

- Mirror Laser Painting Removal

- Mirror Laser Drilling Machine

- Glass Laser Drilling Machine

- Frosted Glass Finishes

- Eco-Friendly Glass Processing

- Smart Mirror Laser Processing

Why Smart Mirror Laser Sanding Is a Game-Changer for Your Glass Business

Still stuck in the past with traditional sandblasting or frosted paint? It’s time to level up. Smart Mirror Laser Sanding is here to revolutionize the way you process glass, offering unbeatable benefits over the old, outdated methods. Here’s why switching to laser sanding will not only save you money but also boost your productivity and make your products stand out.

1. Cut Your Costs: No Consumables, No Problem

- Traditional Sandblasting: You’re constantly replacing abrasives—diamond powder, sand, grit—it’s a never-ending cost.

- Laser Sanding: No consumables. It’s a one-time investment that keeps on giving. You’ll save big on material costs and cut down on waste. Less money spent on replacements means more profit in your pocket.

2. Keep Your Workspace Clean—No Mess, No Dust

- Traditional Methods: Abrasives create a cloud of dust, requiring extra cleanup and protective gear. It’s messy, time-consuming, and can affect your team’s health.

- Laser Sanding: No dust, no debris. It’s contactless and clean—just a focused beam of light that gets the job done. You’re working in a cleaner, safer environment, and your team will thank you.

3. Precision Like Never Before: Perfect Every Time

- Traditional Sandblasting: Achieving the right texture? Good luck. It’s inconsistent, and you’ll often end up with uneven results.

- Laser Sanding: Laser accuracy means you can create intricate patterns, complex textures, and stunning effects on glass—all with flawless precision. No mistakes, no rework, just perfection.

4. Durable Results That Last

- Frosted Paint: Looks good at first, but it wears off over time. You’ll need to touch it up, and your customers won’t be happy when it starts to fade.

- Laser Sanding: The finish created by the laser is permanent. It’s resistant to wear, won’t chip, and stays looking fresh for years. Your customers will love the long-lasting quality.

5. Save Time, Save Money: Automated for Maximum Efficiency

- Traditional Sandblasting: Manual labor, constant adjustments, and slow processing times. It’s inefficient and costly.

- Laser Sanding: With automation in the mix, you’re getting faster production times, reduced labor costs, and better output. More work done in less time, without sacrificing quality.

6. Versatility Across the Board

- Traditional Sandblasting: Can’t handle all types of glass, and the results can be inconsistent depending on the material.

- Laser Sanding: Works perfectly on all types of glass, from smart mirrors to decorative glass, art pieces, and household items. Plus, it’s flexible enough to handle any design challenge you throw at it.

The Takeaway: Switch to Smart Mirror Laser Sanding

If you’re tired of dealing with messy, inefficient, and outdated methods, it’s time to embrace the future with Smart Mirror Laser Sanding. It’s faster, cleaner, more precise, and delivers results that last. By cutting your costs, improving production, and offering better-quality finishes, laser sanding will take your business to the next level.

So, what are you waiting for? Say goodbye to the old way of doing things and embrace the future of glass processing today.

Mirror Laser Sand Blasting Machine Applications

The Mirror Laser Sand Blasting Machine is ideal for a variety of industries. Here’s how it can be used:

1. Smart Mirror Manufacturing

Use the mirror laser sand blasting machine to create frosted effects on smart mirrors. It allows you to add custom patterns and designs to mirrors without the need for films or coatings. This is perfect for high-precision work in smart mirror production.

2. Architectural Glass Processing

This machine is perfect for creating frosted glass and decorative effects on architectural glass. You can use it for windows, partitions, and building facades, adding unique designs to enhance the aesthetics of any structure.

3. Customized Glass Art

For glass artists, the mirror laser sand blasting machine is a game changer. It allows for detailed, precise engraving on glass surfaces, creating personalized and intricate designs on glass art pieces.

4. Automotive Glass Customization

The laser sand blasting machine is great for automotive glass customization. Add branding, logos, or unique designs to car windows and other glass parts. This technology allows you to achieve custom engravings and patterns with ease.

5. Signage and Branding

With the mirror laser sand blasting machine, you can create glass signage and awards by etching logos, names, and designs. It’s perfect for companies looking to make custom glass signs or promotional materials.

6. Mirror Restoration and Repair

This machine is also useful for restoring old mirrors. It can remove scratches, stains, or old coatings to bring mirrors back to life, leaving them with a smooth, fresh finish.

7. Household Glass Items

From glassware to home décor, the mirror laser sand blasting machine allows you to engrave custom designs on various glass products. It’s great for creating personalized gifts or adding unique touches to household items.

Why Choose the Mirror Laser Sand Blasting Machine?

- Precision: Achieve exact designs with high accuracy.

- Eco-friendly: No dust, no chemicals—just clean and efficient processing.

- Durability: The designs last longer and stay intact, unlike painted finishes that may fade or peel.

Frequently Asked Questions (FAQ)

1️⃣ What is a Mirror Laser Sand Blasting Machine used for?

The Mirror Laser Sand Blasting Machine is primarily used for creating mirror finishes, sandblasting surfaces, and removing paint from metal, glass, and other materials. It can create smooth, glossy finishes on surfaces and remove coatings like paint, rust, and oxide layers.

2️⃣ Can this machine remove paint from all types of surfaces?

Yes, the Mirror Laser Sand Blasting Machine is highly effective for removing paint from various surfaces, including metal, glass, plastic, and stone. It’s ideal for paint stripping, surface cleaning, and restoration of materials without damaging the underlying substrate.

3️⃣ What types of materials can be treated with the Mirror Laser Sand Blasting Machine?

This machine is suitable for a wide range of materials including metal, glass, plastic, stone, and ceramics. It’s perfect for industries like automotive, construction, art restoration, and metalworking, where the need for surface treatment and paint removal is critical.

4️⃣ How does the machine create a mirror-like finish?

The Mirror Laser Sand Blasting Machine uses advanced laser technology to sandblast surfaces, creating a reflective, smooth, and glossy finish. By adjusting the laser settings, the machine can create different levels of gloss or matte finishes depending on your project requirements.

5️⃣ Does the machine leave any residue or damage the surface?

No, the Mirror Laser Sand Blasting Machine is designed to be gentle yet effective. It uses laser-based precision sandblasting, meaning it won’t cause damage or leave residue on the material. The painting removal process is also non-abrasive, ensuring the surface stays intact.

6️⃣ How effective is the machine at paint removal?

The laser sandblasting machine provides an extremely efficient way to remove paint without damaging the material underneath. It’s highly effective for removing layers of paint, rust, and oxidation from materials such as automobile parts, metal structures, industrial equipment, and machinery.

7️⃣ Is the machine suitable for industrial use?

Yes, the Mirror Laser Sand Blasting Machine is designed to meet industrial requirements. It’s capable of handling large-scale projects with high efficiency, making it ideal for use in industries such as automotive, construction, manufacturing, and art restoration.

8️⃣ How does the paint removal process work?

The paint removal process is done through laser ablation, where the laser beam is used to break down the paint or coating. It doesn’t use chemicals or abrasives, making it eco-friendly and safe for use in various environments.

9️⃣ Is the machine easy to operate?

Yes, the Mirror Laser Sand Blasting Machine is designed to be user-friendly. It typically comes with an intuitive interface that allows operators to adjust settings such as laser power, speed, and frequency, making it easy to handle even for beginners.

🔟 What is the maintenance required for this machine?

The machine requires minimal maintenance. Regular cleaning of the lens and checking of the laser system are essential to ensure optimal performance. It’s important to ensure that the machine is running in a well-ventilated area to maintain its efficiency.

1️⃣1️⃣ What is the lifespan of the machine?

The Mirror Laser Sand Blasting Machine has a long lifespan if properly maintained. The laser system is designed to withstand continuous use, and with minimal upkeep, you can expect many years of reliable performance.

1️⃣2️⃣ How much power does the machine consume?

The power consumption of the machine will vary based on the model and the material being treated. However, laser-based technology is generally energy-efficient compared to traditional abrasive methods, helping to reduce operational costs.

1️⃣3️⃣ Can the machine work on intricate designs or detailed areas?

Yes, the Mirror Laser Sand Blasting Machine can handle intricate and detailed designs with precision. It allows for fine control in both painting removal and sandblasting, making it suitable for applications that require high levels of detail.

1️⃣4️⃣ Is it eco-friendly?

Yes, the Mirror Laser Sand Blasting Machine is considered eco-friendly since it eliminates the need for harsh chemicals and abrasives used in traditional sandblasting and paint removal methods. It also produces less waste, contributing to a cleaner and more sustainable environment.

Laser Marking Sandblasted Glass Laser Etching Machine

Request a Quote for a Fiber Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

Why Glass Sandlasting with fiber laser marking machine?

March 29, 2024 /0 Comments/in Blog /by lindaCONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am

- EZCAD common errorMarch 18, 2025 - 2:09 am