Author Archive for: linda

About linda

This author has yet to write their bio.Meanwhile lets just say that we are proud linda contributed a whooping 427 entries.

Entries by linda

Relief engraving Die Mould

February 28, 2023 /0 Comments/in Samples Video Collection, Video /by linda

Laser system solutions for mold and die production

3D Cow engraving

Relif engraving sample

Star relief engraving

Name Relif engraving

Coin Relif engraving

Flower Relif engraving

Sun Relif engraving

Deep engraving

Die Mould Relif engraving

Graphic Relif engraving

Flower Coin Relif engraving

Animal engraving

Jewelry Industry-Laser Engraving Cutting Gold/Silver/Brass

February 27, 2023 /0 Comments/in Samples Video Collection, Video /by linda

Jewelry Design Laser Engraving Cutting Machines

Jewelry Client feedback

Gold Sivler Laser Engraving Cutting

Necklace Pattern Laser Engraving Cutting

Ring&Bracelet Laser Engraving

Laser Engraving Photo

Training of Jewelry laser Engraving Cutting

(Split size function)

(RotaryTextMarking)

(Split Size )

Mini Cover Fiber Laser Engraving Cutting Demo Video

(RotaryTextMarking)

(Split Size )

Contact US

Fiber Laser Application

February 27, 2023 /0 Comments/in Samples Video Collection, Video /by linda2.5D EZCAD 3.0 Fiber Laser Marking Cutting Machine

February 24, 2023 /0 Comments/in Products /by linda

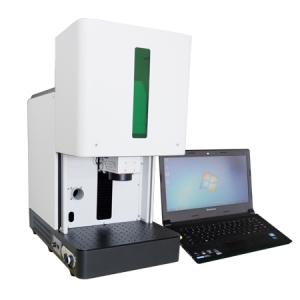

2.5D Fiber Laser Marking Machine

2.5D EZCAD 3.0 Fiber Laser Marking Cutting Machine

2.5D EzCAD 3.0 Fiber Laser Engraving Machine

It is the upgrading system based on 2D laser.

Unlock precision with the 2.5D EzCAD 3.0 Fiber Laser. Engineered for 2D and 3D relief engraving on flat surfaces, this machine features motorized Z-axis auto-focus and advanced EZCAD 3.0 software for effortless, high-quality results. Perfect for fine details on metals, plastics, and more.

Note: It’s ideal for flat materials, but not for 3D engraving on curved surfaces.

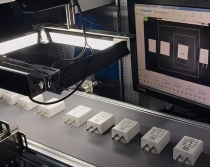

Hot Selling Model of 2.5D Laser Marking Machine

Mini Fiber Laser

Mini Cover Fiber Laser

2.5D EZCAD 3.0 Laser detail info

2.5D EzCAD 3.0 Fiber Laser Marking & Engraving Machine – Advanced Laser Technology for Precision and Versatility

The 2.5D EzCAD 3.0 Fiber Laser Marking & Engraving Machine is the latest upgrade to the traditional 2D laser system, offering enhanced capabilities for both 2D and 3D laser engraving. This powerful machine integrates advanced features, including a motorized Z-axis auto-focus function and the EZCAD 3.0 software, designed specifically for 3D relief engraving on flat surfaces.

Key Features:

-

Motorized Z-Axis Auto Focus: This feature automatically adjusts the focus of the laser based on the surface of your material, ensuring optimal precision and consistency in engraving. Say goodbye to manual focus adjustments and save valuable time in your workflow.

-

EZCAD 3.0 Software: Known for its user-friendly interface, this upgraded software allows for effortless 3D relief engraving. The intuitive controls make it easy for operators to create complex designs, with unparalleled accuracy, on a wide variety of materials.

-

2D & 2.5D Engraving: While the 2.5D laser engraving machine excels in traditional 2D laser work, it also enables high-quality 3D relief engraving on flat surfaces. This provides added versatility compared to standard 2D systems, making it perfect for a variety of applications, including jewelry, metal, plastics, and more.

What You Need to Know:

-

2.5D Engraving Limitations: Although the 2.5D fiber laser engraving machine can handle 3D relief engraving on flat plates, it cannot perform true 3D engraving on curved or irregular surfaces. If you need to engrave 3D designs on complex geometries, a specialized 3D laser system may be more suitable.

-

Ideal for Multiple Industries: Whether you’re in jewelry design, metal engraving, or plastic marking, this machine offers the flexibility to handle a wide range of materials and applications. The combination of 2D precision and 3D relief engraving makes it a versatile tool for professionals looking to take their engraving capabilities to the next level.

-

Enhanced Productivity: With faster processing times and automated adjustments, the 2.5D fiber laser engraving machine streamlines production, allowing businesses to complete more projects in less time without compromising quality.

Why Choose the 2.5D EzCAD 3.0 Fiber Laser Engraving Machine?

-

Unmatched Precision: The motorized Z-axis auto-focus and EZCAD 3.0 software ensure perfect results every time, whether you are marking simple 2D designs or intricate 3D relief engravings.

-

Cost-Effective Solution: For businesses that require a high degree of engraving versatility without the high cost of a full 3D laser system, the 2.5D machine is the ideal compromise, offering a powerful solution for flat-surface 3D relief engraving at a more affordable price point.

-

Easy Integration into Your Workflow: The user-friendly interface and automated functions make it easy to integrate into existing production lines, boosting productivity without the need for specialized operators.

Parameters for the Mini Fiber Laser Engraving & Cutting Machine for Jewelry:

| Item | Specification |

|---|---|

| Laser Parameters | |

| Optical Maser | JPT M7 |

| Laser Wavelength | 1064nm |

| Average Output Power | 60W |

| Light Isolation | Yes |

| Modulation Frequency Range | 20kHz ~ 80kHz |

| Galvo Parameters | |

| Maximum Speed | 7000mm/s |

| Resolution | 0.001mm |

| Repositioning Precision | ±0.003mm |

| Optical Output Characteristics | |

| Marking Area | 110*110mm |

| Minimum Line Width | 0.01mm |

| Minimum Height of Characters | 0.2mm |

| Cooling System | |

| Cooling Way | Air Cooling |

| System Properties | |

| Laser Power Supply | 0.5KW/AC220V/50Hz~60Hz (optional 110V) |

| Environmental Requirements | 0 ~ 35°C, 90% humidity |

Whether you’re looking for a jewelry laser cutting machine for custom engravings, personalized jewelry marking, or professional gold and silver cutting, the Mini Fiber Laser Marking Machine is the best choice to elevate your business and increase your production capabilities.

Advantages: 2.5D EzCAD 3.0 Fiber Laser Marking & Engraving Machine

-

Precision Auto-Focus

Equipped with a motorized Z-axis auto-focus, this machine automatically adjusts the focal distance based on the material surface, ensuring optimal engraving results and saving you time on manual adjustments. -

2D & 3D Engraving Capabilities

The 2.5D machine not only handles 2D laser engraving but also supports 3D relief engraving on flat surfaces, making it ideal for intricate designs on metals, plastics, wood, and more. -

EZCAD 3.0 Software Integration

Powered by EZCAD 3.0 software, it offers easy-to-use controls and powerful features for creating detailed, high-precision 3D relief effects, allowing you to take your designs to the next level with ease. -

High-Efficiency Production

With fast engraving speeds, this machine can significantly boost production efficiency, making it perfect for businesses needing high-output with consistent quality. -

Versatile for Multiple Materials & Industries

Whether you’re working with jewelry, metal plaques, plastic marking, or other materials, the 2.5D EzCAD 3.0 Fiber Laser Machine delivers exceptional performance, making it a versatile solution for various industries. -

Cost-Effective Solution

Combining 2D and 3D engraving functions into one machine, this solution offers the best of both worlds at a more affordable price than standalone 3D laser systems, giving you more value for your investment.

Applications of the 2.5D EzCAD 3.0 Fiber Laser Marking Machine

The 2.5D EzCAD 3.0 Fiber Laser Marking Machine is designed for high-precision metal marking and engraving, offering both 2D and 3D relief engraving on flat metal surfaces.

Key Applications:

-

Jewelry Marking: Ideal for engraving intricate designs, logos, and text on metal jewelry like rings and bracelets. It supports 3D relief effects for added detail.

-

Metal Parts & Components: Perfect for marking serial numbers, barcodes, and logos on metal parts in industries like automotive, aerospace, and electronics.

-

Plaques & Tags: Engrave nameplates and metal tags with precision and 3D relief effects for enhanced branding.

-

Industrial & Electronic Marking: Ideal for marking metal parts in industries requiring durability, such as electronics, automotive, and aerospace.

-

Custom Gifts & Promotional Items: Perfect for engraving personalized metal gifts, trophies, and promotional items with 3D effects for a unique, high-end finish.

Why Choose the 2.5D EzCAD 3.0?

- High Precision on metal surfaces.

- 3D relief engraving for added depth and detail.

- Fast, durable, and cost-effective for high-volume production.

Frequently Asked Questions (FAQ) – 2.5D Fiber Laser Marking Machine

1️⃣ What is a 2.5D Fiber Laser Marking Machine?

A 2.5D Fiber Laser Marking Machine is a high-precision laser system that combines the benefits of traditional 2D laser marking with depth control for more complex designs. This technology allows for engraving or marking that includes depth variations, making it ideal for creating 3D-like effects, such as relief marking, logo engraving, and barcodes on curved or uneven surfaces.

2️⃣ How is a 2.5D Fiber Laser Marking Machine different from a 2D system?

While traditional 2D laser marking is flat and only provides surface engraving, a 2.5D fiber laser adds the ability to control the depth of the engraving. This allows for more intricate designs and three-dimensional effects on materials, making it suitable for deep engraving, textured surfaces, or part marking on non-flat objects.

3️⃣ What materials can the 2.5D Fiber Laser Marking Machine process?

This machine is designed to work with a wide range of materials, including:

- Metals: Steel, aluminum, copper, titanium, gold, silver, etc.

- Plastics: ABS, PVC, polycarbonate, etc.

- Ceramics: Tiles, porcelains, etc.

- Glass: For engraving logos or creating 3D designs.

- Composites: Carbon fiber, fiberglass, etc.

The depth control makes it especially effective for processing harder materials and creating intricate details.

4️⃣ How does the depth control work in a 2.5D Fiber Laser Marking Machine?

The depth control works by adjusting the focus and laser power to vary the engraving depth. By precisely controlling the laser’s movement and focus point, the system can create shallow or deep marks, allowing for detailed relief engraving, textures, and logos on uneven or curved surfaces. The machine can also adjust the depth of engraving on multi-layered materials for more complex projects.

5️⃣ What are the key advantages of using a 2.5D Fiber Laser Marking Machine?

- High Precision: Achieve extremely accurate marks with high depth control for a 3D effect on materials.

- Versatile Applications: Ideal for marking or engraving on irregular surfaces such as cylindrical, curved, or 3D parts.

- Deep Engraving: Offers the ability to engrave deeper than traditional 2D machines, perfect for texturing, logos, or serial numbers.

- Clean & High-Quality Results: Produces smooth, clean marks with no residue, reducing the need for post-processing.

- Cost-Effective & Efficient: The fiber laser is energy-efficient, provides fast processing, and ensures long-term durability with minimal maintenance.

6️⃣ What are some common applications for the 2.5D Fiber Laser Marking Machine?

The 2.5D fiber laser is perfect for applications where depth, texture, or relief is required:

- Aerospace: Engraving detailed part markings, serial numbers, or logos on curved or irregular parts.

- Automotive: Marking VIN numbers, engine parts, and custom designs on metal and plastic components.

- Electronics: Creating detailed engravings on circuit boards, chips, and connectors.

- Jewelry: Engraving intricate designs or 3D logos on rings, necklaces, and bracelets.

- Medical Devices: Engraving serial numbers or labels on medical instruments and implants.

- Tooling & Manufacturing: Marking parts and tools with barcodes or technical data.

7️⃣ What is the marking area of the 2.5D Fiber Laser Marking Machine?

The marking area generally ranges from 50mm x 50mm to 300mm x 300mm, depending on the specific model. Some models may offer customizable marking sizes to accommodate larger or more complex components.

8️⃣ Is the 2.5D Fiber Laser Marking Machine easy to operate?

Yes, the 2.5D Fiber Laser Marking Machine comes with user-friendly software and an intuitive control interface. The machine allows for easy depth adjustments, pattern uploads, and real-time monitoring of the engraving process. Additionally, it’s designed to require minimal training, making it suitable for both beginners and professionals.

9️⃣ Can the 2.5D Fiber Laser Marking Machine be used for batch production?

Yes, the 2.5D Fiber Laser Marking Machine is ideal for batch production. Its high-speed operation and precision allow for continuous processing of multiple parts, making it suitable for high-volume production lines. The automatic depth control ensures consistent quality across all pieces.

🔟 How does the machine handle materials of different thicknesses or sizes?

The 2.5D Fiber Laser Marking Machine can easily adjust its focus to accommodate different thicknesses and sizes of materials. The focus lens can be changed, and the laser power can be adjusted to create the desired engraving depth and quality, regardless of the material’s thickness. This flexibility makes it ideal for multi-material production and handling a variety of products.

1️⃣1️⃣ What maintenance is required for the 2.5D Fiber Laser Marking Machine?

Routine maintenance includes:

- Cleaning the lens and mirrors to maintain optimal performance.

- Inspecting the laser for any signs of wear.

- Checking the cooling system to ensure the machine operates at the right temperature.

- Periodically calibrating the system to maintain depth accuracy.

- Software updates for new features or improvements.

1️⃣2️⃣ How much does a 2.5D Fiber Laser Marking Machine cost?

The price varies depending on the laser power, marking area, and specific features such as depth control and additional customizations. Generally, the price range is between $15,000 to $60,000, depending on the configuration and requirements.

2.5D EZCAD 3.0 Fiber Laser Laser Marking Cutting Video

Request a Quote for a Green Laser Marking Machine

SISMAR LASER has green laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality green laser marking machine that exceeds your expectations. You can also schedule a demo to see how green laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.

How to choose the best handheld fiber laser welding machine?

February 6, 2023 /0 Comments/in Blog /by lindaRelief Engraving on Lighter industry

July 6, 2022 /0 Comments/in Blog /by linda2.5D Laser VS 3D Laser COMPARISON

November 5, 2021 /0 Comments/in Blog /by lindaEverything you need know about optical fiber laser metal cutting technology

June 29, 2021 /0 Comments/in Blog /by lindaCONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-59535285

Fax: +86-531-59535285

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Glass Laser Drilling Machine: Precision Drilling for Float & Ultra-Clear Glass (3–6mm)December 16, 2025 - 4:01 am

- 🔥 800×800mm Large Format Laser Marking Machine – Industrial Laser Engraving SystemDecember 15, 2025 - 8:06 am

- Why Choose a Laser Marking Machine with Modular Sliding Platform for Your FactoryDecember 15, 2025 - 7:10 am

- Troubleshooting Steps for “IPG Laser: Over Temperature” ErrorAugust 15, 2025 - 6:00 am

- EZCAD common errorMarch 18, 2025 - 2:09 am