1300*2500mm Mirror Laser Sand Blasting Machine

/0 Comments/in Products /by linda

Smart Mirror Laser Sand Blasting & Painting Removal Machine – High-Precision Industrial Solution

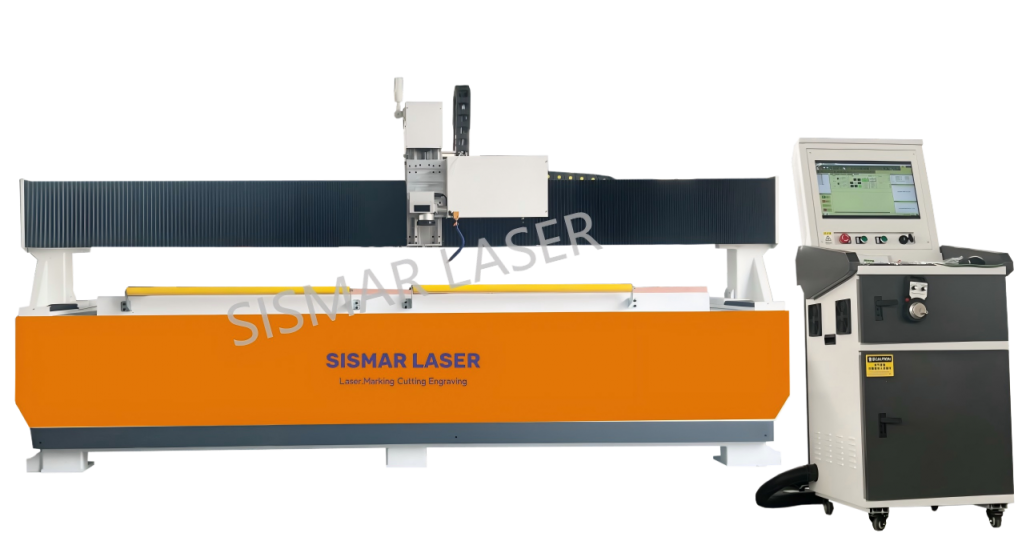

1300 × 2500 mm Workspace | Fiber Laser Etching & Mirror Laser Processing System for Smart Mirrors

The Smart Mirror Laser Sand Blasting Machine and Mirror Laser Painting Removal Machine provide industrial-grade precision for smart mirror production.

Featuring a 1300 × 2500 mm working area and an aluminum hollow platform, it supports both smart mirror laser etching and clean paint removal while efficiently managing smoke and debris.

Equipped with a 120W fiber laser and high-speed galvo scanning, this mirror laser processing system ensures consistent matte surfaces, sharp edges, and optimal repeatability.

Ideal for smart mirrors, coated glass, and decorative applications, it streamlines production, reduces labor, and enhances quality—making it perfect for manufacturers and distributors aiming for efficiency and superior results.

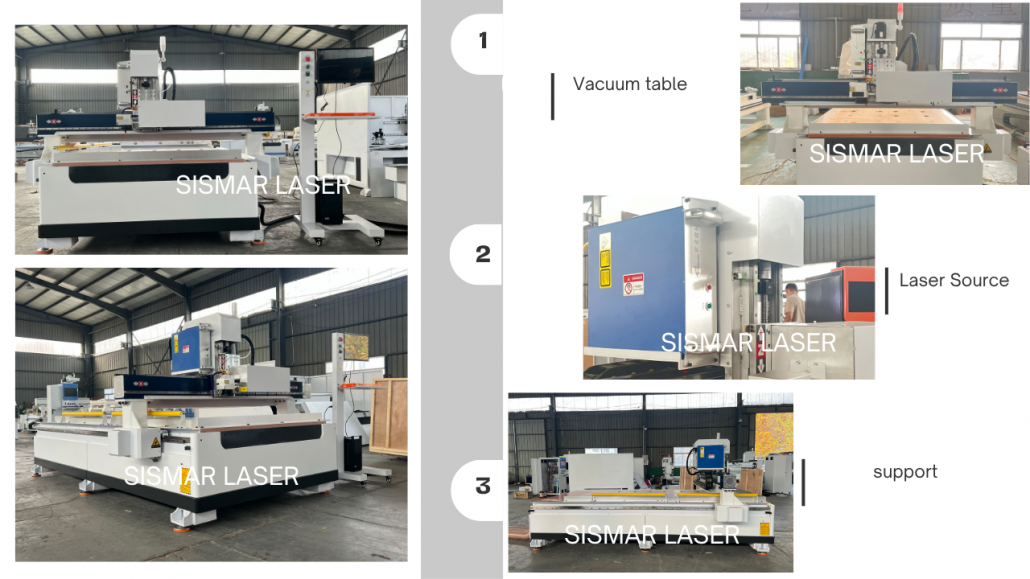

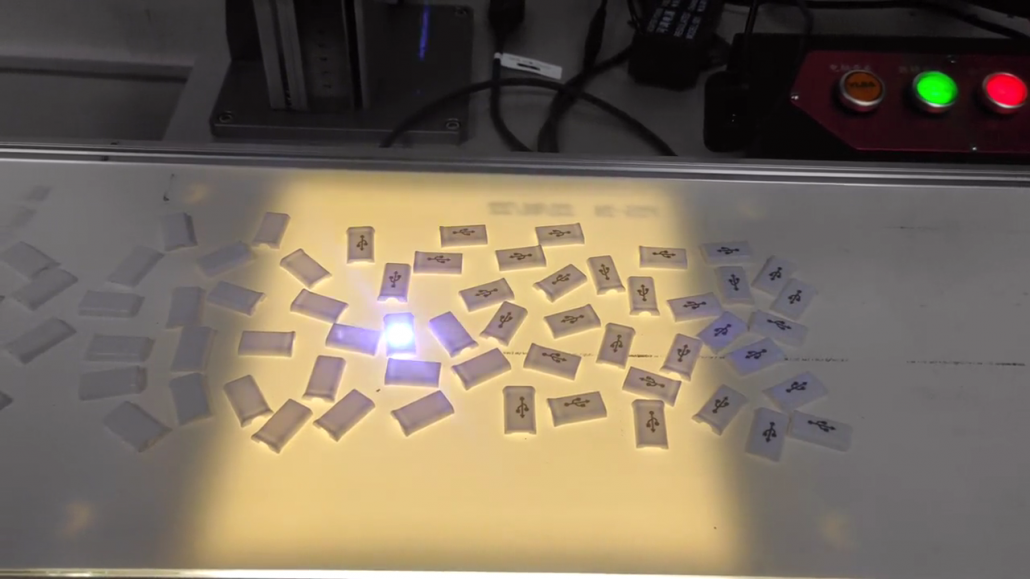

Machine Photos of Sand Blasting Mirror Laser Machine

Smart Mirror Laser Sand Blasting & Painting Removal Machine

Industrial-Grade 1300 × 2500 mm Workspace | High-Speed Galvo | Next-Generation Smart Mirror Processing

Smart mirrors are not just reflective surfaces—they are interfaces, lifestyle enhancements, and brand statements.

Their quality is defined by precision, consistency, and clarity.

Our mirror laser sand blasting machine and mirror laser painting removal machine redefine what smart mirror production can achieve.

Designed for manufacturers and distributors alike, this machine delivers:

High-speed, high-precision laser processing

Clean, uniform matte surfaces

Efficient paint removal without damage

Integrated debris and smoke management

With 1300 × 2500 mm industrial workspace, it accommodates large mirrors for mass production, while maintaining premium quality standards.

01 / Large-Format Laser System for Smart Mirrors

The smart mirror industry demands larger panels:

bathroom mirrors, fitness mirrors, hotel mirrors, interactive displays, and smart home installations.

Machine Highlights:

Full 1300 × 2500 mm working area: process large mirrors in one pass

Single-pass finishing: no repositioning, no segmenting, no alignment errors

Uniform pattern quality across the entire surface

Reduced manual labor: faster production, lower operational cost

Large-format processing ensures consistent smart mirror laser etching results, elevating the perceived product value for end users.

02 / Aluminum Hollow-Structure Platform: Precision & Efficiency

The aluminum hollow platform is engineered for maximum stability and multi-functionality.

Optimized for smart mirror sandblasting: smooth, even support protects coatings, heating films, and conductive layers

Supports both drilling and laser machining: debris from drilling falls into hollow cavities, avoiding contamination or damage

Integrated multi-point smoke extraction: ensures a clean workspace and consistent matte finish

Single platform for multiple processes: sandblasting, laser painting removal, and drilling completed without repositioning

This platform ensures production efficiency while maintaining mirror integrity, making it ideal for industrial smart mirror workflows.

03 / 120W Orion / GZ Laser Source: Precision & Reliability

High-power laser output ensures clean, sharp, and repeatable results:

Fine, uniform matte surfaces for premium interface quality

Efficient paint removal for coating layers without burn or smearing

Edge sharpness perfect for UI icons, symbols, logos, and touch zones

Continuous high-volume production without thermal distortion

Whether used as a mirror laser sand blasting machine or mirror laser painting removal machine, this laser guarantees optical-grade precision.

04 / Syntec Smart Mirror Processing System: Speed, Accuracy, Consistency

The Syntec control system allows:

Complex vector pattern processing at high speed

Fine laser modulation for multi-layer coatings

Stable performance for long-duration production

Consistent results for batch processing

With integrated mirror laser processing system logic, even the most intricate smart mirror layouts—UI icons, interactive panels, and gradient zones—are reproduced with absolute accuracy.

05 / High-Speed Galvo & Quartz F-Theta Lens: Micron-Level Detail

High-speed galvo scanning reduces processing time while maintaining precision

Quartz F-Theta lens ensures uniform beam quality across the full mirror surface

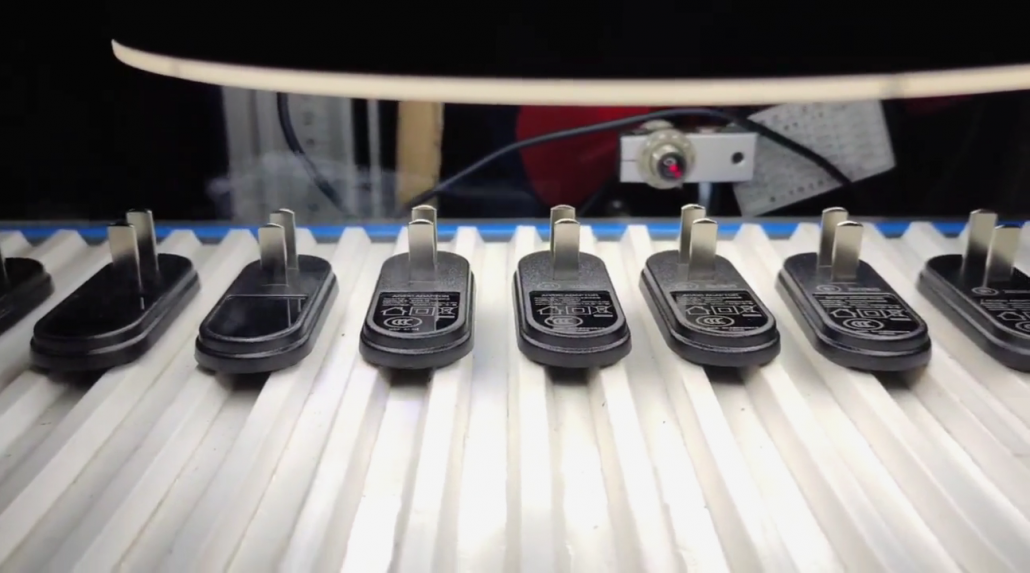

Ideal for intricate smart mirror etching, logo engraving, and UI interface marking

Every detail is accurately represented, achieving a “finished product” effect directly from the machine—no additional processing required.

06 / Industrial Advantages for Smart Mirror Manufacturers

Key Benefits:

Premium matte finishes for a superior visual experience

High throughput for large-format smart mirrors

No abrasive media or post-cleaning required

Repeatable precision for mass production

Compatible with various mirror coatings and smart mirror layouts

This system transforms smart mirror production into a high-precision, high-efficiency, high-quality workflow.

07 / Distributor Benefits

Capitalize on a rapidly expanding smart mirror market

Unique mirror laser sand blasting machine technology with high entry barriers

Low-maintenance hardware for smooth operations

Ideal for OEM brands, mirror factories, smart home integrators

Easily demonstrated and sold with clear ROI

This machine is not just equipment—it’s a marketable technology solution.

08 / Technical Specifications

| Parameter | Specification |

|---|---|

| Machine Type | Mirror Laser Sand Blasting & Painting Removal Machine |

| Laser Source | Ouling / Raycus 120W |

| Max Working Area | 1300 × 2500 mm |

| Platform Type | Aluminum Hollow-Structure Platform |

| Processing Speed | Up to 6000 mm/s (Galvo scanning) |

| Laser Wavelength | 1064 nm (Fiber Laser) |

| Software | Syntec Smart Mirror Processing System |

| Supported Materials | Smart mirrors, coated glass, regular glass |

| Cooling System | Water-cooled with thermal protection |

| Dust & Smoke Management | Integrated multi-point extraction & filters |

| Repeatability | ±0.02 mm |

| Power Supply | 380V / 50Hz |

| Dimensions (L×W×H) | 4500 × 2300 × 2300 mm |

| Weight | 1450 kg |

Why Smart Mirror Laser Sanding Is a Game-Changer for Your Glass Business

Still stuck in the past with traditional sandblasting or frosted paint? It’s time to level up. Smart Mirror Laser Sanding is here to revolutionize the way you process glass, offering unbeatable benefits over the old, outdated methods. Here’s why switching to laser sanding will not only save you money but also boost your productivity and make your products stand out.

1. Cut Your Costs: No Consumables, No Problem

- Traditional Sandblasting: You’re constantly replacing abrasives—diamond powder, sand, grit—it’s a never-ending cost.

- Laser Sanding: No consumables. It’s a one-time investment that keeps on giving. You’ll save big on material costs and cut down on waste. Less money spent on replacements means more profit in your pocket.

2. Keep Your Workspace Clean—No Mess, No Dust

- Traditional Methods: Abrasives create a cloud of dust, requiring extra cleanup and protective gear. It’s messy, time-consuming, and can affect your team’s health.

- Laser Sanding: No dust, no debris. It’s contactless and clean—just a focused beam of light that gets the job done. You’re working in a cleaner, safer environment, and your team will thank you.

3. Precision Like Never Before: Perfect Every Time

- Traditional Sandblasting: Achieving the right texture? Good luck. It’s inconsistent, and you’ll often end up with uneven results.

- Laser Sanding: Laser accuracy means you can create intricate patterns, complex textures, and stunning effects on glass—all with flawless precision. No mistakes, no rework, just perfection.

4. Durable Results That Last

- Frosted Paint: Looks good at first, but it wears off over time. You’ll need to touch it up, and your customers won’t be happy when it starts to fade.

- Laser Sanding: The finish created by the laser is permanent. It’s resistant to wear, won’t chip, and stays looking fresh for years. Your customers will love the long-lasting quality.

5. Save Time, Save Money: Automated for Maximum Efficiency

- Traditional Sandblasting: Manual labor, constant adjustments, and slow processing times. It’s inefficient and costly.

- Laser Sanding: With automation in the mix, you’re getting faster production times, reduced labor costs, and better output. More work done in less time, without sacrificing quality.

6. Versatility Across the Board

- Traditional Sandblasting: Can’t handle all types of glass, and the results can be inconsistent depending on the material.

- Laser Sanding: Works perfectly on all types of glass, from smart mirrors to decorative glass, art pieces, and household items. Plus, it’s flexible enough to handle any design challenge you throw at it.

The Takeaway: Switch to Smart Mirror Laser Sanding

If you’re tired of dealing with messy, inefficient, and outdated methods, it’s time to embrace the future with Smart Mirror Laser Sanding. It’s faster, cleaner, more precise, and delivers results that last. By cutting your costs, improving production, and offering better-quality finishes, laser sanding will take your business to the next level.

So, what are you waiting for? Say goodbye to the old way of doing things and embrace the future of glass processing today.

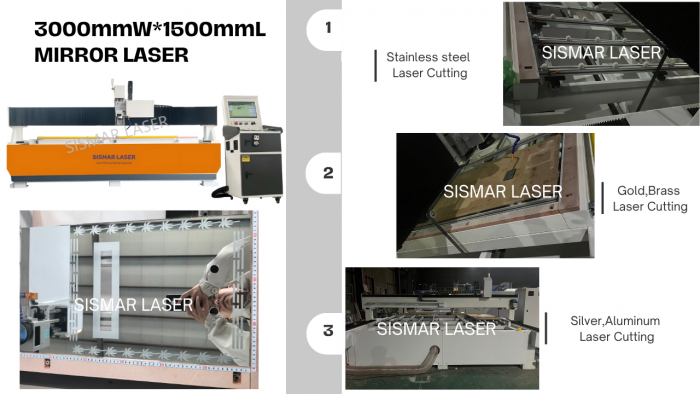

Mirror Laser Sand Blasting Machine Applications

The Mirror Laser Sand Blasting Machine is ideal for a variety of industries. Here’s how it can be used:

1. Smart Mirror Manufacturing

Use the mirror laser sand blasting machine to create frosted effects on smart mirrors. It allows you to add custom patterns and designs to mirrors without the need for films or coatings. This is perfect for high-precision work in smart mirror production.

2. Architectural Glass Processing

This machine is perfect for creating frosted glass and decorative effects on architectural glass. You can use it for windows, partitions, and building facades, adding unique designs to enhance the aesthetics of any structure.

3. Customized Glass Art

For glass artists, the mirror laser sand blasting machine is a game changer. It allows for detailed, precise engraving on glass surfaces, creating personalized and intricate designs on glass art pieces.

4. Automotive Glass Customization

The laser sand blasting machine is great for automotive glass customization. Add branding, logos, or unique designs to car windows and other glass parts. This technology allows you to achieve custom engravings and patterns with ease.

5. Signage and Branding

With the mirror laser sand blasting machine, you can create glass signage and awards by etching logos, names, and designs. It’s perfect for companies looking to make custom glass signs or promotional materials.

6. Mirror Restoration and Repair

This machine is also useful for restoring old mirrors. It can remove scratches, stains, or old coatings to bring mirrors back to life, leaving them with a smooth, fresh finish.

7. Household Glass Items

From glassware to home décor, the mirror laser sand blasting machine allows you to engrave custom designs on various glass products. It’s great for creating personalized gifts or adding unique touches to household items.

Why Choose the Mirror Laser Sand Blasting Machine?

- Precision: Achieve exact designs with high accuracy.

- Eco-friendly: No dust, no chemicals—just clean and efficient processing.

- Durability: The designs last longer and stay intact, unlike painted finishes that may fade or peel.

Frequently Asked Questions (FAQ)

1️⃣ What is a Mirror Laser Sand Blasting Machine used for?

The Mirror Laser Sand Blasting Machine is primarily used for creating mirror finishes, sandblasting surfaces, and removing paint from metal, glass, and other materials. It can create smooth, glossy finishes on surfaces and remove coatings like paint, rust, and oxide layers.

2️⃣ Can this machine remove paint from all types of surfaces?

Yes, the Mirror Laser Sand Blasting Machine is highly effective for removing paint from various surfaces, including metal, glass, plastic, and stone. It’s ideal for paint stripping, surface cleaning, and restoration of materials without damaging the underlying substrate.

3️⃣ What types of materials can be treated with the Mirror Laser Sand Blasting Machine?

This machine is suitable for a wide range of materials including metal, glass, plastic, stone, and ceramics. It’s perfect for industries like automotive, construction, art restoration, and metalworking, where the need for surface treatment and paint removal is critical.

4️⃣ How does the machine create a mirror-like finish?

The Mirror Laser Sand Blasting Machine uses advanced laser technology to sandblast surfaces, creating a reflective, smooth, and glossy finish. By adjusting the laser settings, the machine can create different levels of gloss or matte finishes depending on your project requirements.

5️⃣ Does the machine leave any residue or damage the surface?

No, the Mirror Laser Sand Blasting Machine is designed to be gentle yet effective. It uses laser-based precision sandblasting, meaning it won’t cause damage or leave residue on the material. The painting removal process is also non-abrasive, ensuring the surface stays intact.

6️⃣ How effective is the machine at paint removal?

The laser sandblasting machine provides an extremely efficient way to remove paint without damaging the material underneath. It’s highly effective for removing layers of paint, rust, and oxidation from materials such as automobile parts, metal structures, industrial equipment, and machinery.

7️⃣ Is the machine suitable for industrial use?

Yes, the Mirror Laser Sand Blasting Machine is designed to meet industrial requirements. It’s capable of handling large-scale projects with high efficiency, making it ideal for use in industries such as automotive, construction, manufacturing, and art restoration.

8️⃣ How does the paint removal process work?

The paint removal process is done through laser ablation, where the laser beam is used to break down the paint or coating. It doesn’t use chemicals or abrasives, making it eco-friendly and safe for use in various environments.

9️⃣ Is the machine easy to operate?

Yes, the Mirror Laser Sand Blasting Machine is designed to be user-friendly. It typically comes with an intuitive interface that allows operators to adjust settings such as laser power, speed, and frequency, making it easy to handle even for beginners.

🔟 What is the maintenance required for this machine?

The machine requires minimal maintenance. Regular cleaning of the lens and checking of the laser system are essential to ensure optimal performance. It’s important to ensure that the machine is running in a well-ventilated area to maintain its efficiency.

1️⃣1️⃣ What is the lifespan of the machine?

The Mirror Laser Sand Blasting Machine has a long lifespan if properly maintained. The laser system is designed to withstand continuous use, and with minimal upkeep, you can expect many years of reliable performance.

1️⃣2️⃣ How much power does the machine consume?

The power consumption of the machine will vary based on the model and the material being treated. However, laser-based technology is generally energy-efficient compared to traditional abrasive methods, helping to reduce operational costs.

1️⃣3️⃣ Can the machine work on intricate designs or detailed areas?

Yes, the Mirror Laser Sand Blasting Machine can handle intricate and detailed designs with precision. It allows for fine control in both painting removal and sandblasting, making it suitable for applications that require high levels of detail.

1️⃣4️⃣ Is it eco-friendly?

Yes, the Mirror Laser Sand Blasting Machine is considered eco-friendly since it eliminates the need for harsh chemicals and abrasives used in traditional sandblasting and paint removal methods. It also produces less waste, contributing to a cleaner and more sustainable environment.

Laser Marking Sandblasted Glass Laser Etching Machine

Request a Quote for a Fiber Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality fiber laser marking machine that exceeds your expectations. You can also schedule a demo to see how fiber laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.