3D Green Laser Single-Sphere Crystal Laser Engraving Machine

/0 Comments/in Products /by linda

3D Green Laser Single-Sphere Crystal Laser Engraving Machine

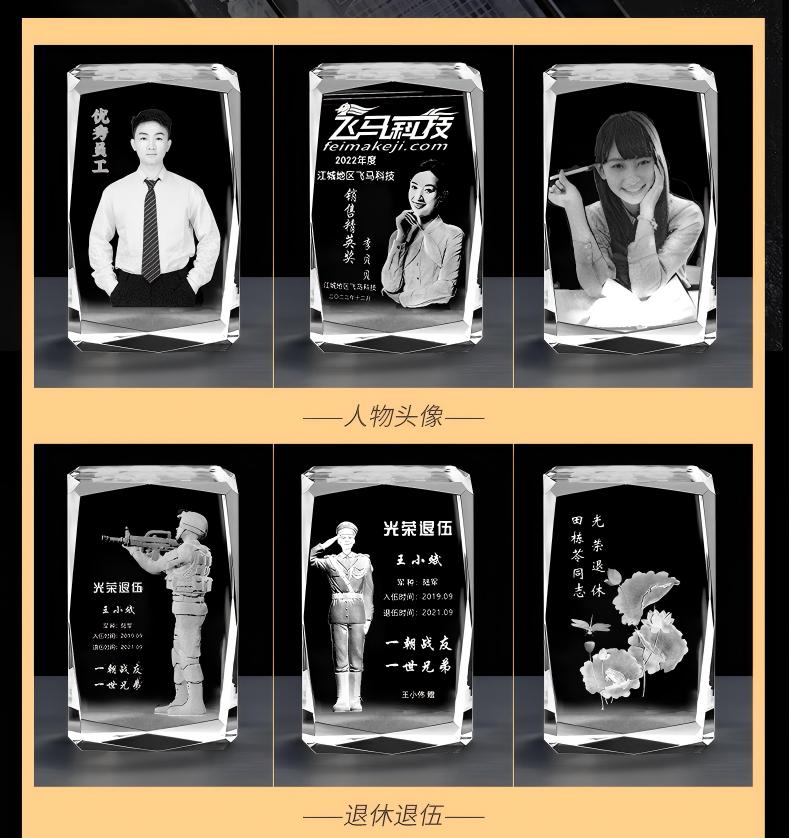

Turn Ordinary Photos Into Extraordinary Crystal Masterpieces – A Profitable Business in a Box

3D Green Laser Single-Sphere Crystal Engraving Machine

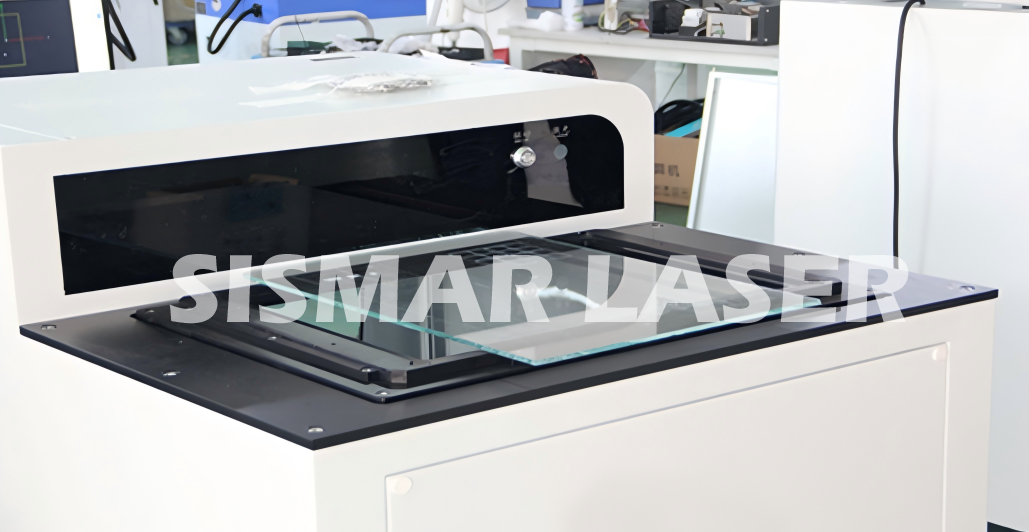

Take your crystal gift business to the next level with our high-precision green laser crystal engraving machine. Designed for single-sphere crystal engraving and small crystal cube customization, this machine delivers sharp, detailed 3D images inside glass or crystal with incredible speed and accuracy. Its compact size, built-in touchscreen display, and WiFi photo upload function make it easy to operate — no external computer required. Perfect for entrepreneurs, gift shops, and studios seeking professional 3D laser crystal engraving solutions.

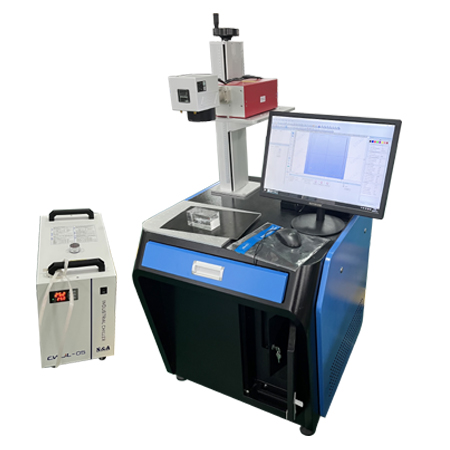

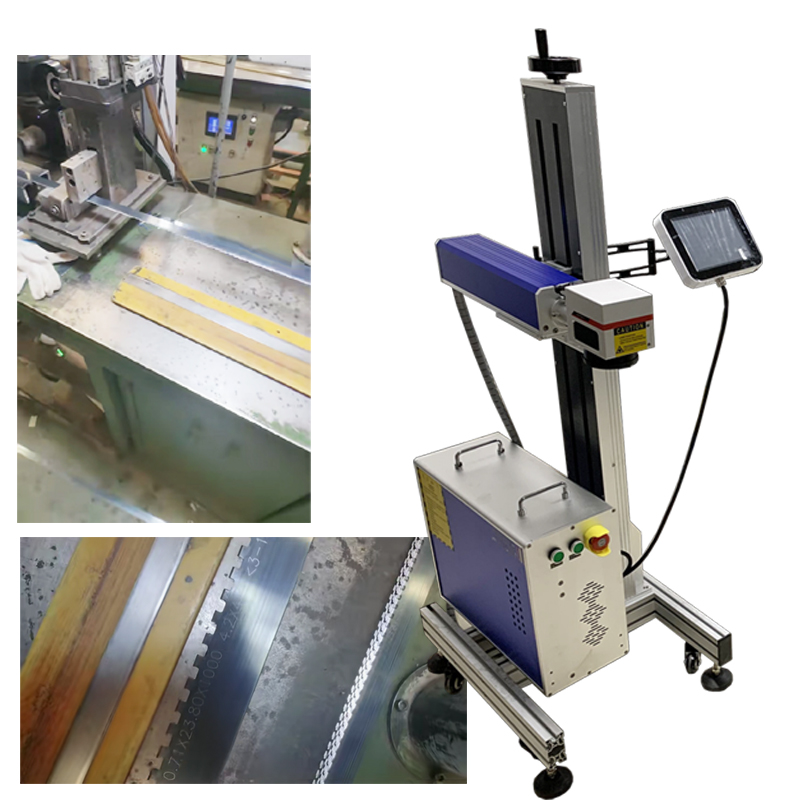

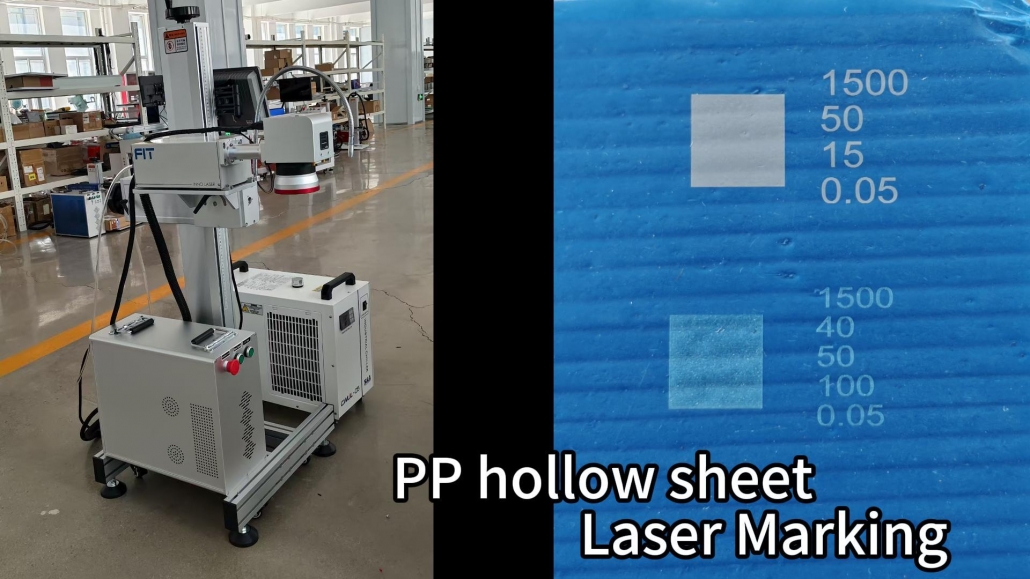

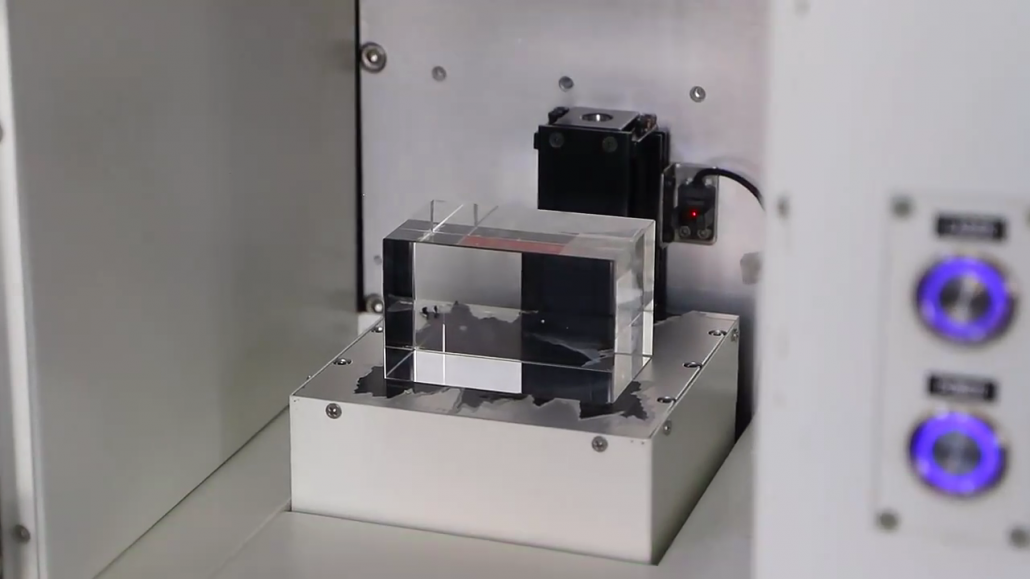

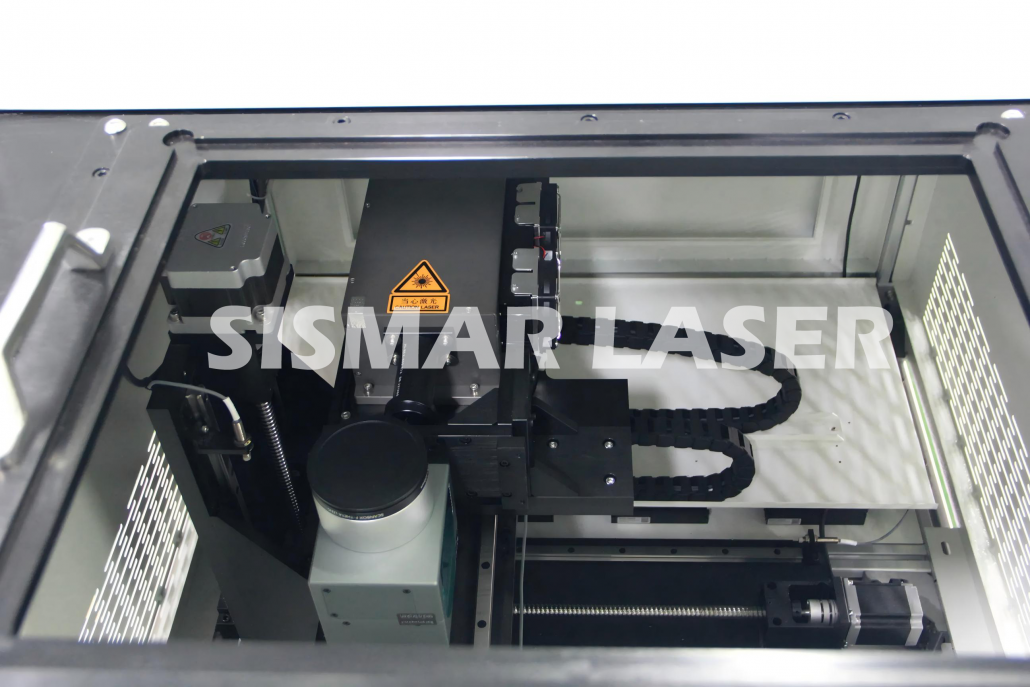

Machine Photos of 3D subsurface laser engraving machine

– Introduction & Product Overview

🚀 A Profitable, Creative, and Future-Proof Business Idea

Are you looking for a business that delivers jaw-dropping products your customers can’t stop talking about?

If you’ve ever admired those 3D photo crystals that capture memories inside a polished glass block or crystal ball, now is your chance to own the technology that makes them—without spending a fortune or hiring a team of technicians.

🌟 Product Overview: 3D Green Laser Single-Sphere Crystal Laser Engraving Machine

The 3D Green Laser Single-Sphere Crystal Laser Engraving Machine is a compact, high-precision engraving solution for crystal spheres, crystal cubes, and other glass products.

Unlike bulky traditional machines, this eco-friendly, Wi-Fi-enabled system delivers automation, simplicity, and profit potential—all in one machine.

If you’ve been searching for a crystal cube laser inside engraving machine that is affordable, versatile, and business-ready, this is your competitive edge.

– Key Advantages & Features

⚠️ Why Most People Fail with Laser Engraving (And How You Won’t)

Many entrepreneurs hesitate to enter the personalization market because:

❌ High upfront costs of traditional engraving equipment

❌ Complicated software with a steep learning curve

❌ Bulky, industrial machines that don’t fit in small businesses

Our Solution:

✅ So simple, anyone can use it

✅ So compact, it fits in any shop or studio

✅ So efficient, it pays for itself in months

🔥 Fully Automated 3D Engraving – The Game-Changer

📱 Mobile Uploads, No PC Needed – Scan, upload, engrave directly from your phone

🤖 Smart 3D Model Generation – Automatic photo-to-3D conversion

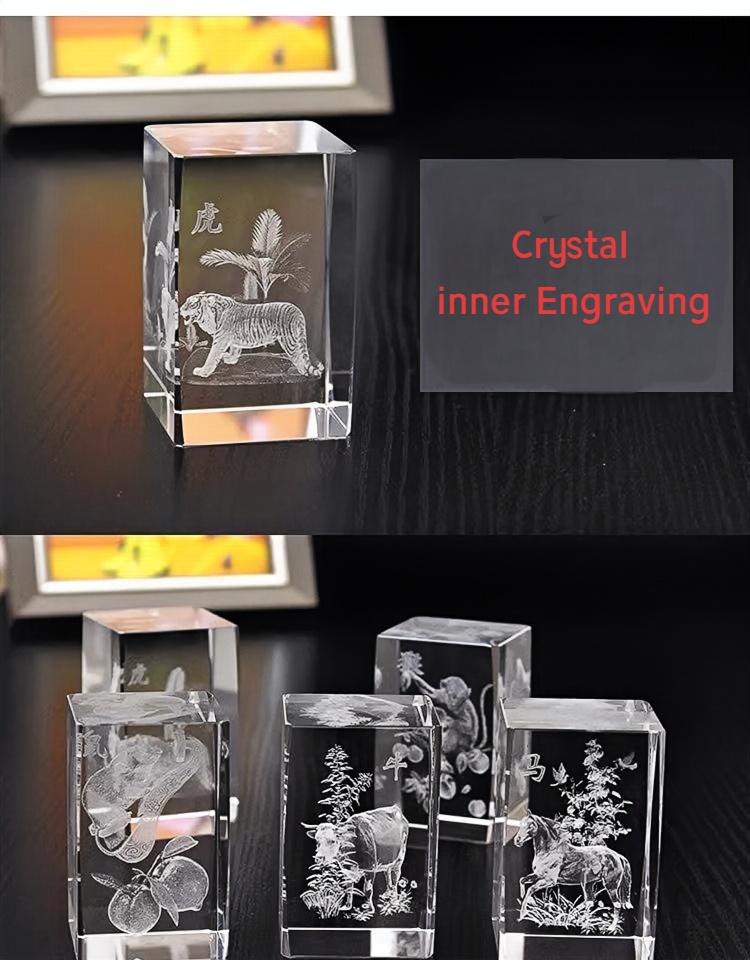

🖼️ All-in-One Functionality – 2D, 3D, and photo engraving in one system

🔗 Flexible Formats – Accepts JPG, GLB, and more

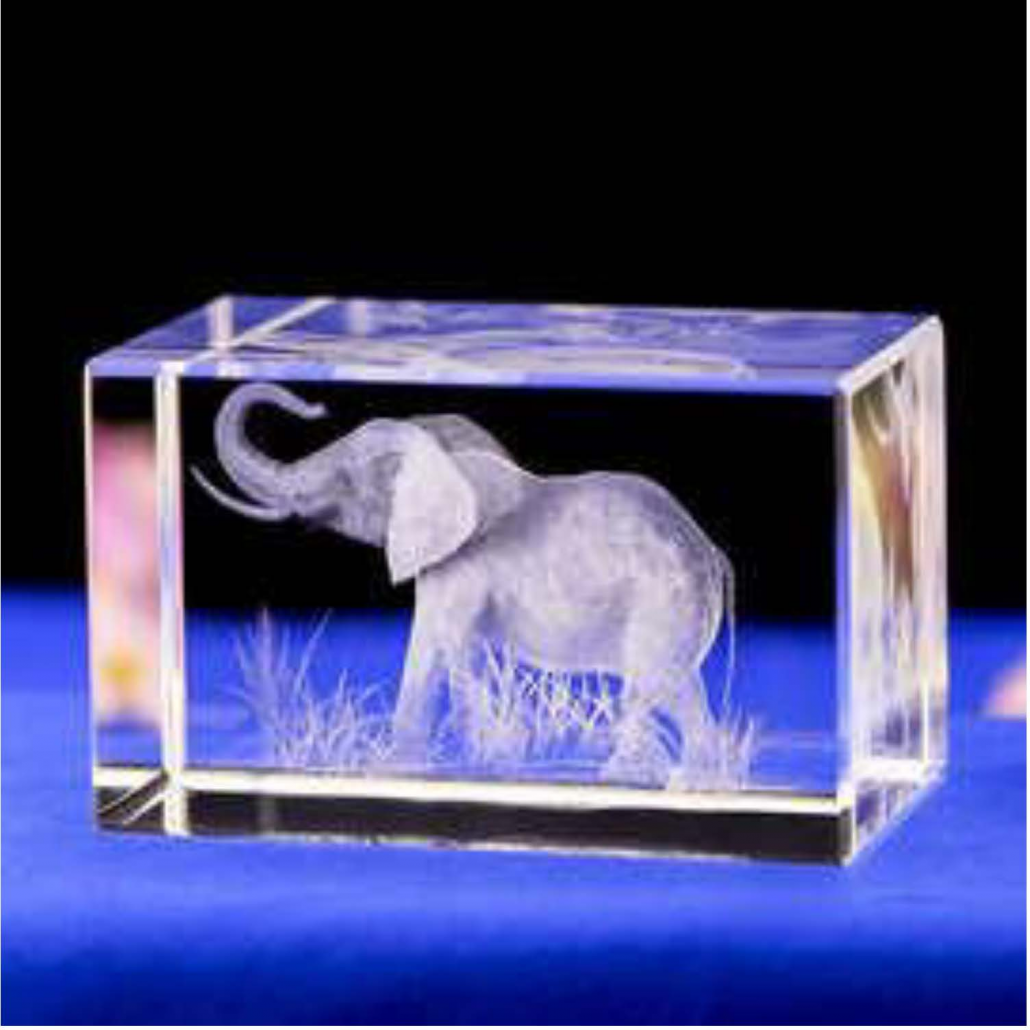

🎁 Endless Product Possibilities

Personalized gifts and keepsakes

Awards, trophies, and corporate gifts

Souvenirs and event mementos

Custom art and décor pieces

🏪 Designed for Businesses Like Yours

📏 Compact, Shop-Ready Design: 62×65×60cm footprint

🪨 Rock-Solid Stability: 75kg build for vibration-free engraving

🔄 Sphere & Cube Versatility: Up to Ø70mm spheres, 70×70×100mm cubes

🌬️ Silent, Clean Operation: Air-cooled and dust-free

💡 Why Green Laser? The Secret to Superior Quality

✅ Sharper, higher-resolution engraving

✅ Crisp, vibrant photo reproduction

✅ 20,000-hour laser lifespan

✅ 300W low power consumption

– Business Opportunity & Technical Info

💰 ROI: From Startup to Profitable in Months

Crystal blanks cost just a few dollars

Engraved crystals retail for $100+

One day of orders could cover your machine cost in months

Turnkey business opportunity designed for quick scaling

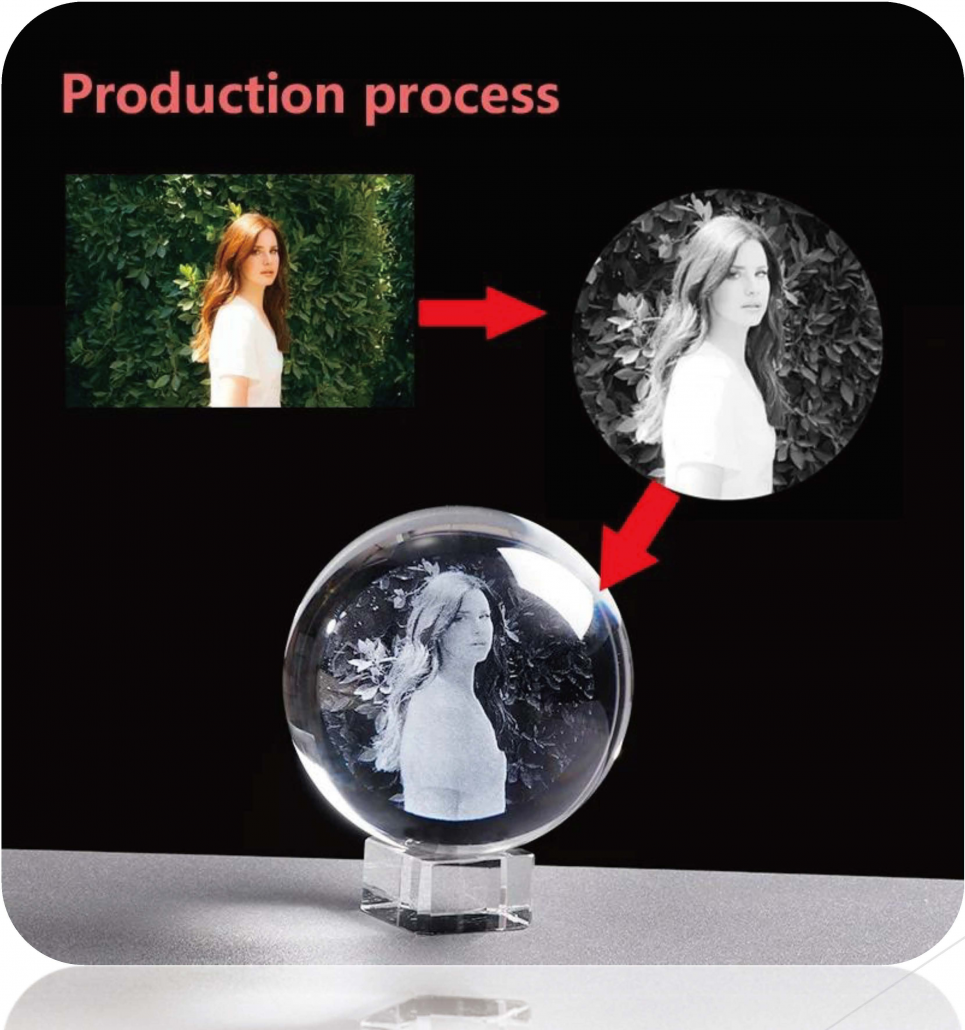

🔑 Simple 5-Step Workflow

📲 Scan QR Code – Customers upload their favorite photo

🤖 AI-Powered 3D Model – Machine auto-converts image

🖼️ Select Engraving Mode – Choose 2D, 3D, or photo

🔥 Start Engraving – Watch the design come alive

🎁 Deliver the Product – Hand over a premium keepsake

🛠️ Technical Specs at a Glance

| Feature | Specification |

|---|---|

| Laser Wavelength | 532 nm (Green Laser) |

| Output Power | ~887.9 mW |

| Max Engraving | Ø 70 mm |

| Engraving Speed | 3000 dots/sec |

| Resolution | 500–1200 DPI |

| Supported | Crystal Sphere, Crystal Cube |

| Size/Weight | 62×65×60 cm / 75 kg |

| Cooling | Air-Cooled |

| Laser Lifetime | 20,000 hours |

🏆 Built for Entrepreneurs Who Want Freedom

📦 Portable and event-friendly setup

🎨 Creative flexibility with high profit margins

🔧 Low operating costs, high returns

🤝 After-Sales Support You Can Trust

🔒 1-Year Warranty – Full coverage on all parts

📞 Lifetime Tech Support – Phone, chat, remote video

💻 Free Software Updates – Stay ahead of competitors

FAQ – 3D Green Laser Single-Sphere Crystal Laser Engraving Machine

1. What materials can I engrave with this machine?

You can engrave crystal spheres, crystal cubes, and other glass products. The machine supports a variety of shapes and sizes up to Ø70mm for spheres and 70×70×100mm for cubes.

2. How does the 3D engraving process work?

Simply scan the QR code on the machine, upload a photo from your phone, and the system will automatically generate a 3D model and engrave it inside the crystal. No PC or CAD software is needed.

3. Is this machine suitable for small shops or home businesses?

Yes! With its compact design (62×65×60 cm) and stable 75kg frame, the machine fits easily in gift shops, kiosks, photography studios, or home-based businesses.

4. What file formats does the machine support?

The system accepts JPG, GLB, and other popular file types, giving you flexibility for 2D, 3D, and photo engraving.

5. How precise is the laser engraving?

Equipped with a 532nm green laser, the machine produces high-resolution engravings (500–1200 DPI), capturing intricate details and producing vibrant, crisp 3D images.

6. How long does the laser last?

The laser module has a lifespan of approximately 20,000 hours, ensuring long-term reliability and low maintenance costs.

7. How energy-efficient is the machine?

The device uses only ≈300W, and its air-cooled system ensures silent, dust-free, and eco-friendly operation.

8. Can the machine handle bulk orders?

Yes! With optional jigs and adjustable motion platforms, you can engrave multiple sizes and designs efficiently, making it ideal for high-volume production.

9. What is the typical ROI for this machine?

Crystal blanks cost only a few dollars each, while engraved 3D crystals can retail for $100+. Many businesses recoup their machine cost in just a few months, depending on daily order volume.

10. What support and warranty are provided?

1-Year Warranty: Full coverage for all parts.

Lifetime Technical Support: Assistance via phone, chat, or remote video.

Free Software Updates: Keep your machine updated with new features and improvements.

11. Is the machine easy to use for beginners?

Absolutely! The fully automated workflow allows anyone to start engraving without prior laser or CAD experience. Just upload the photo and start engraving.

12. Can I engrave both spheres and cubes in the same machine?

Yes! The machine is designed for versatility, allowing you to switch between crystal spheres and cubes easily with adjustable jigs.

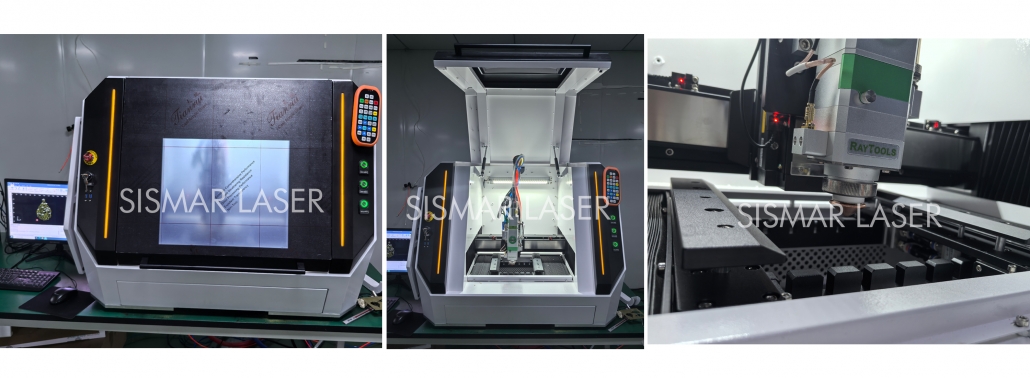

Working Video of 3D Crystal Laser Marking Machine

Request a Quote for a 3D crystal Green Laser Marking Machine

SISMAR LASER has fiber laser machines and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser marking system or an excellent choice for your first laser machine.

Request a quote for a high-quality 3D crystal r laser marking machine that exceeds your expectations. You can also schedule a demo to see how 3D crystal Green laser marking works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.