150W 200W Benchtop Jewelry Laser Welding Machine

/0 Comments/in Products /by linda

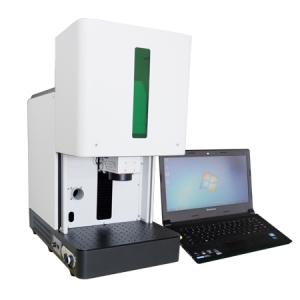

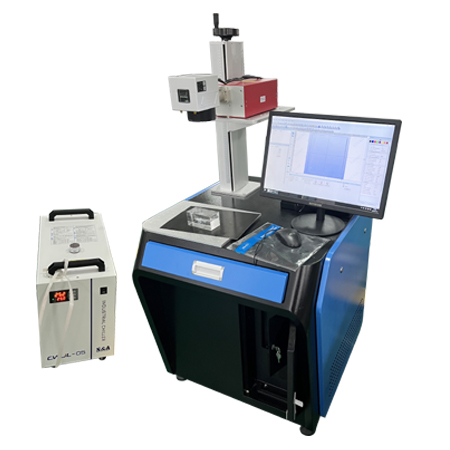

BenchTop Jewelry Laser Welding Machine

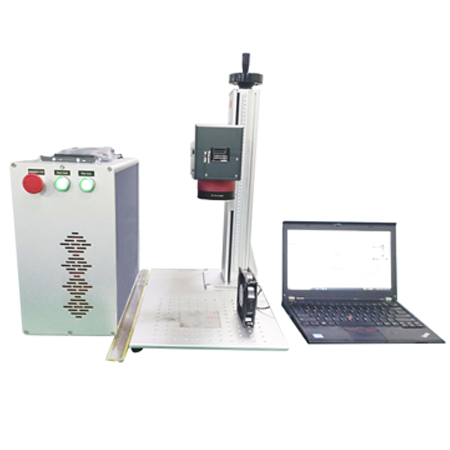

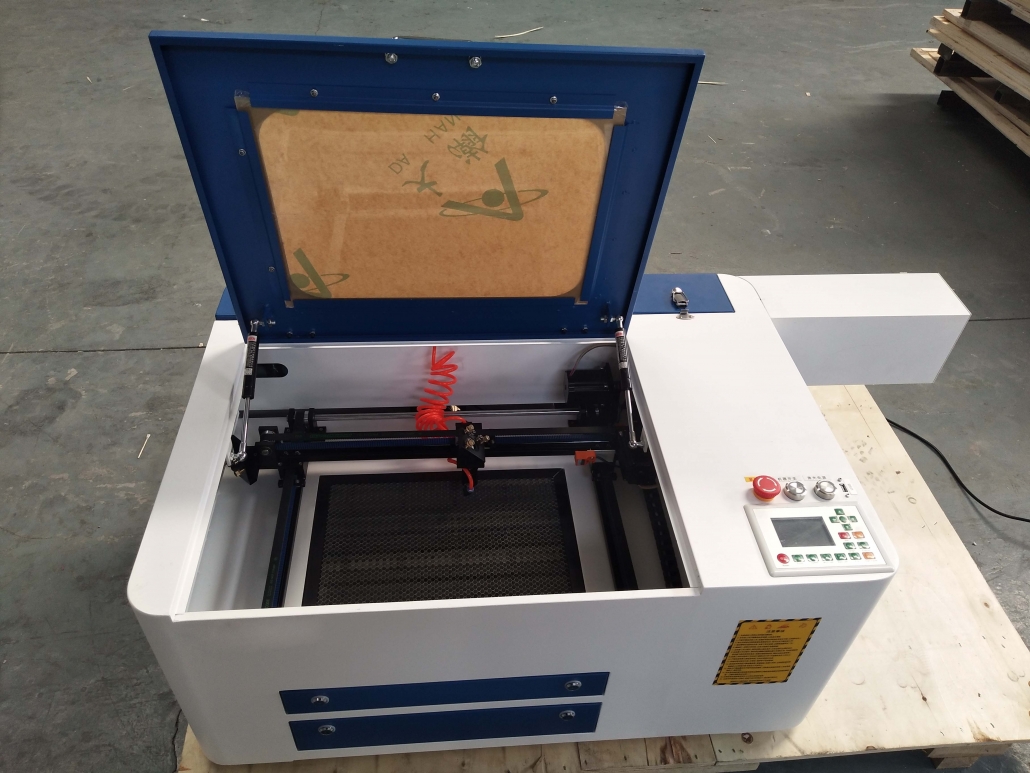

Introducing our Benchtop Jewelry Laser Welding Machine – the perfect solution for jewelers looking for a space-saving yet powerful tool. This compact machine combines high precision and efficiency, making it ideal for jewelry repair and design in limited spaces without compromising performance.

Key Features:

- Space-Saving Design: Compact size fits perfectly in small workshops, allowing you to maximize workspace while still benefiting from powerful capabilities.

- Precision Welding: Perfect for delicate tasks such as prong, setting, and chain repairs, ensuring clean, accurate welds without damaging surrounding materials.

- Versatile Applications: Ideal for a range of metals including gold, silver, platinum, and titanium, making it perfect for resizing rings, repairing prongs, fixing chains, and addressing porosity issues.

- User-Friendly: Easy to operate, making it suitable for jewelers of all experience levels.

Perfect for small workshops, retail stores, or any space where efficiency and quality are paramount, this machine is designed to enhance your business while saving precious workspace.

BenchTop Jewelry Laser Welding Machine

Introducing the Benchtop Jewelry Laser Welding Machine — the ultimate solution for jewelers looking to elevate their craft. Whether you’re working in a compact space or need something to handle higher demands, this jewelry laser welding machine offers three power options: 100W, 150W, and 200W. No matter the power level you choose, you’ll get precise, reliable welding that suits your needs.

Power Options for Every Need:

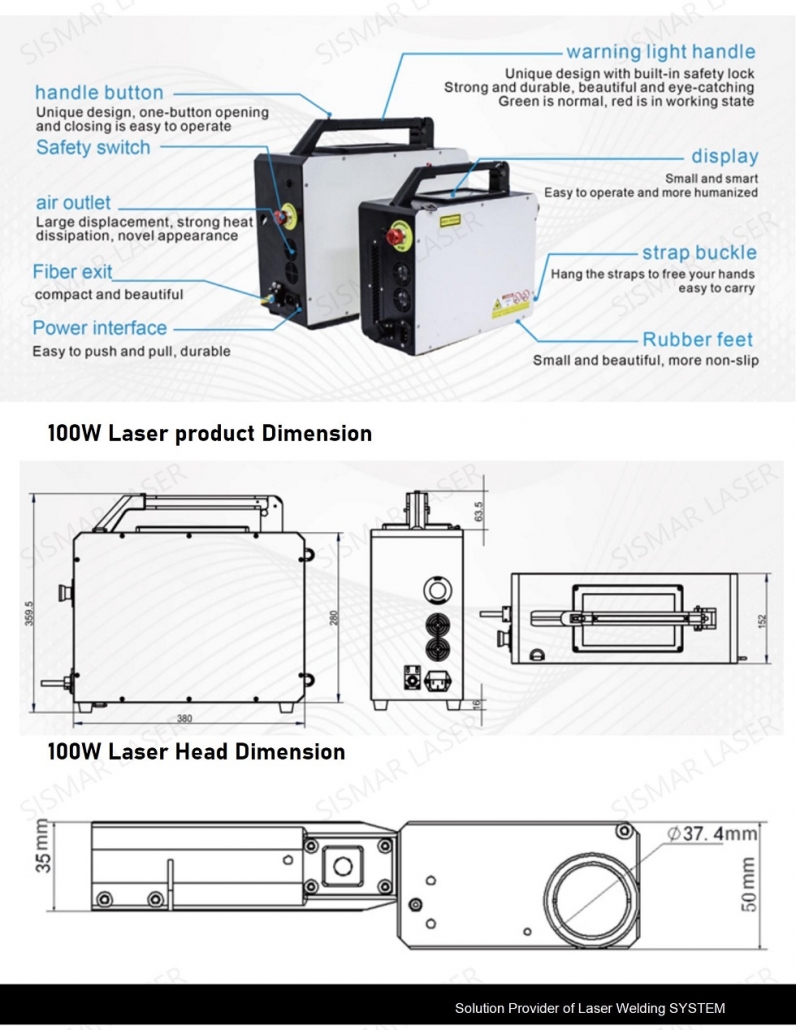

100W Model: Perfect for light to medium jewelry repairs, this jewelry laser welding machine works wonders on smaller tasks like resizing rings, repairing prongs, or fixing delicate chains. However, to keep things running smoothly, it’s best to use this model in a well-ventilated room, preferably with air conditioning. It’s not recommended for extended use without proper cooling, as it can overheat, limiting performance.

150W Model: The 150W version strikes a perfect balance — small in size, but big on power. Ideal for jewelers who have limited space but still need reliable performance, this option delivers the precision you need for standard jewelry repairs. It’s a great upgrade from the 100W, offering more power without taking up much more space.

200W Model: Need extra power for bigger, more intricate jobs? The 200W jewelry laser welding machine is your go-to tool. It’s built for high-demand tasks, making quick work of larger repairs or thick metals. If your jewelry shop is bustling with activity and you need something that can handle speed and precision, this is the model for you.

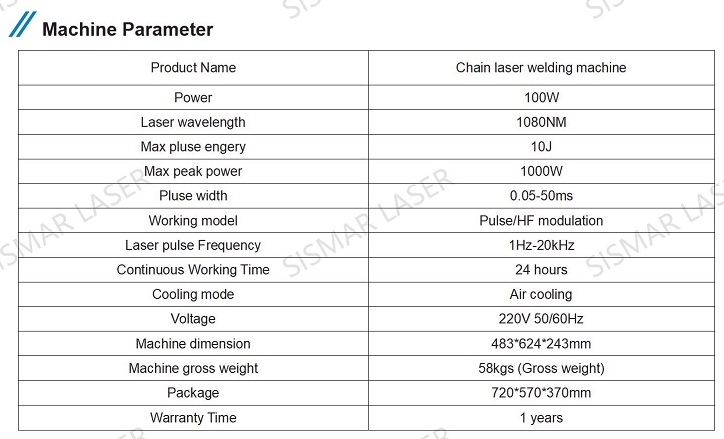

Benchtop Jewelry Laser Welding Machine Specifications

Looking for a powerful, space-saving solution for your jewelry repair and design needs? Our Benchtop Jewelry Laser Welding Machine is available in three models—100W, 150W, and 200W—giving you the flexibility to choose the right machine for your workspace and workload.

| Feature | 100W Model | 150W Model | 200W Model |

|---|---|---|---|

| Laser Type | Nd:YAG 1064 nm | Nd:YAG 1064 nm | Nd:YAG 1064 nm |

| Average Power | 100W | 150W | 200W |

| Peak Power | 3.5 kW | 7.2 kW | 8 kW |

| Energy Range | 0.1 – 80 J | 0.1 – 180 J | 0.1 – 200 J |

| Pulse Duration | 0.1 – 25 milliseconds | 0.1 – 25 milliseconds | 0.1 – 25 milliseconds |

| Welding Frequency | 1 – 30 Hz | 1 – 30 Hz | 1 – 30 Hz |

| Spot Diameter | 0.2 – 2.0 mm | 0.2 – 2.0 mm | 0.2 – 2.0 mm |

| Input Power | 110 or 230 V AC, 50/60 Hz, Single Phase | 110 or 230 V AC, 50/60 Hz, Single Phase | 110 or 230 V AC, 50/60 Hz, Single Phase |

| Dimensions (L×W×H) | 76 × 53 × 56 cm | 76 × 53 × 56 cm | 76 × 53 × 56 cm |

| Weight | ~43 kg | ~43 kg | ~43 kg |

Why Choose Our Benchtop Jewelry Laser Welding Machine?

When you need precision and performance in a compact design, this machine checks all the boxes. Whether you’re running a small workshop or tackling high-demand jobs, here’s what you can expect:

- Compact Yet Powerful: Say goodbye to bulky equipment. These machines offer robust performance without taking up your precious workspace.

- Perfect for Jewelry Repairs: Whether you’re resizing rings, fixing chains, or welding prongs, this machine does it all with laser accuracy.

- User-Friendly: Don’t be intimidated—our easy-to-use interface lets you weld with precision, no matter your skill level.

Which Model Is Right for You?

100W Model: If you’re handling light to medium jewelry repairs and have access to an air-conditioned room for cooling, this is a great choice. It’s perfect for jewelers in smaller, more controlled environments.

150W Model: This one strikes the perfect balance between power and size. Small enough to fit into tight spaces, yet powerful enough for standard repairs. If you’re ready to take your welding to the next level, this is your go-to option.

200W Model: Need speed and power for demanding projects? The 200W machine delivers quick, strong welds for even the toughest tasks. Ideal for high-volume production spaces or complex repairs.

Applications for the Benchtop Jewelry Laser Welding Machine:

- Ring Resizing: Adjust sizes easily and accurately. Perfect fit, every time.

- Prong Repair: Secure your gemstones with precision welding that strengthens prongs.

- Chain Repair: Fix broken chains with seamless welds that restore their original integrity.

- Porosity Filling: Eliminate casting defects and ensure that every piece is structurally sound.

Invest in the Benchtop Jewelry Laser Welding Machine today and start delivering high-quality repairs and designs with ease, precision, and speed. Whether you’re working in a small space or need a powerhouse for high-demand tasks, we’ve got you covered.

Why Choose Our Benchtop Jewelry Laser Welding Machine?

Space-Saving, High-Power Design: Each model is compact, saving you valuable workspace without sacrificing power. Whether you’re welding gold, silver, or titanium, you’ll get top-notch results every time.

Versatility Across Tasks: From resizing rings and fixing chains to repairing prongs and filling porosity, this machine’s versatility makes it perfect for every type of jewelry repair.

Reliable Cooling and Consistent Performance: The 200W model features advanced cooling technology, keeping the machine performing at its peak even during extended use.

No matter which power option you choose, our Benchtop Jewelry Laser Welding Machine ensures that your jewelry repair process is faster, more precise, and space-efficient. Ready to upgrade your shop with the best in jewelry laser welding technology? The choice is simple.

🔧 Why Choose the Benchtop Jewelry Laser Welding Machine?

If you’re looking to level up your jewelry repair and design game, the Benchtop Jewelry Laser Welding Machine could be your secret weapon. It’s not just compact and powerful, it offers several distinct advantages over other types of jewelry laser welding machines. Here’s why this space-saving solution might be the perfect fit for your shop:

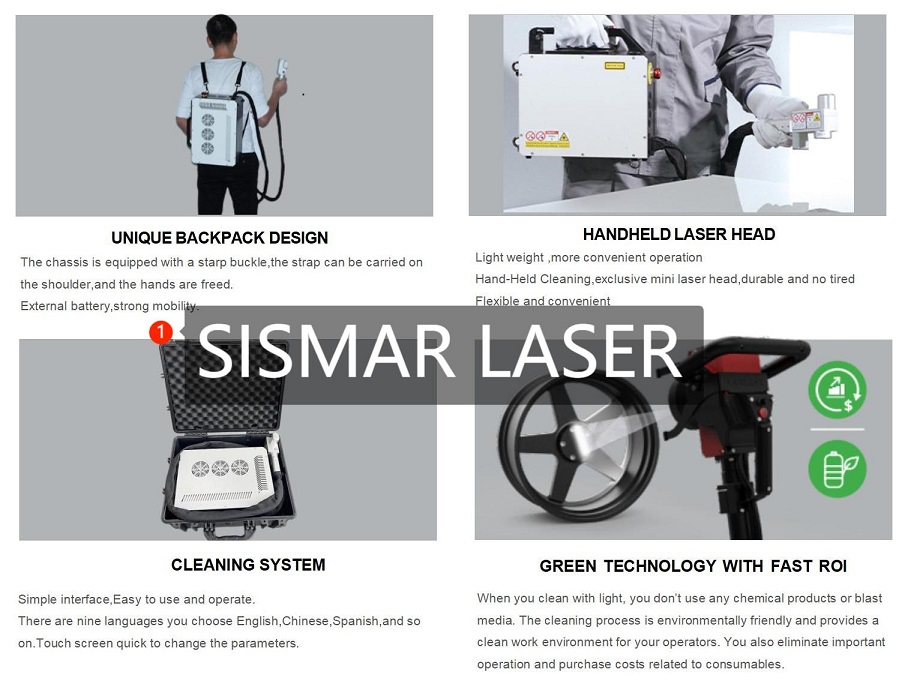

1. 🌟 Space-Saving Design – Perfect for Small Spaces

One of the biggest benefits of the Benchtop Jewelry Laser Welding Machine is its small footprint. Unlike larger industrial laser welders, this model doesn’t take up valuable space in your workshop. It’s ideal for jewelers with limited room but who still need precision and power.

💡 Key Benefit: It’s compact enough to fit in tight spaces, making it perfect for small workshops or retail setups.

2. ⚡ Flexible Power Options for Versatile Use

The Benchtop Jewelry Laser Welding Machine comes in three different power configurations: 100W, 150W, and 200W. This range allows you to choose the ideal power level that best suits your needs.

- 100W: Great for light repairs. However, it works best in a controlled, air-conditioned environment.

- 150W: Perfect balance of power and compact design, making it great for standard repairs.

- 200W: Ideal for more demanding tasks and thicker metals. Best for high-performance jobs.

🔑 Tip: Pick the right power to optimize your workflow!

3. 💎 High Precision and Clean Joints

Precision is the core strength of the Benchtop Jewelry Laser Welding Machine. Whether you’re resizing rings, repairing prongs, or fixing delicate chains, expect clean, accurate welds every time.

✔️ Benefits:

- Minimal heat to protect delicate gemstones.

- Focused laser beam ensures perfect bonding without the need for extra filler.

4. 🧑🏫 User-Friendly and Easy to Operate

The Benchtop Jewelry Laser Welding Machine is designed with ease of use in mind. Even beginners can get started quickly, thanks to its intuitive controls. Unlike more complex machines, this model requires no steep learning curve.

5. 🔨 Ideal for Small to Medium Jewelry Jobs

Perfect for custom pieces or delicate repairs, the Benchtop Jewelry Laser Welding Machine is made for small to medium-sized tasks. It’s not for mass production, but precision crafting—ideal for jewelers who specialize in unique or intricate designs.

🔍 Best For:

- Ring resizing

- Prong repairs

- Chain fixes

6. 💰 Affordable and Energy Efficient

Looking for a cost-effective solution? The Benchtop Jewelry Laser Welding Machine offers powerful results without breaking the bank. It’s more energy-efficient than larger models, helping you save on utility costs while delivering high-quality welds.

7. 🔥 Less Heat, Less Risk

Since this machine uses a focused laser beam, there’s significantly less heat than traditional welding methods. This means less risk of warping your metals or damaging gemstones.

💡 Why it matters:

- Stronger, more durable welds.

- No compromise on the integrity of your work.

🌟 Key Takeaways:

The Benchtop Jewelry Laser Welding Machine is a game-changer for jewelers. With its space-saving design, customizable power options, and precision welding, it’s the perfect solution for small to medium-sized jewelry repairs and designs. Whether you’re upgrading your current equipment or just starting, this machine will help you get the job done faster and better.

🔧 Ready to elevate your jewelry business? The Benchtop Jewelry Laser Welding Machine is here to help you create beautiful, intricate jewelry with ease.

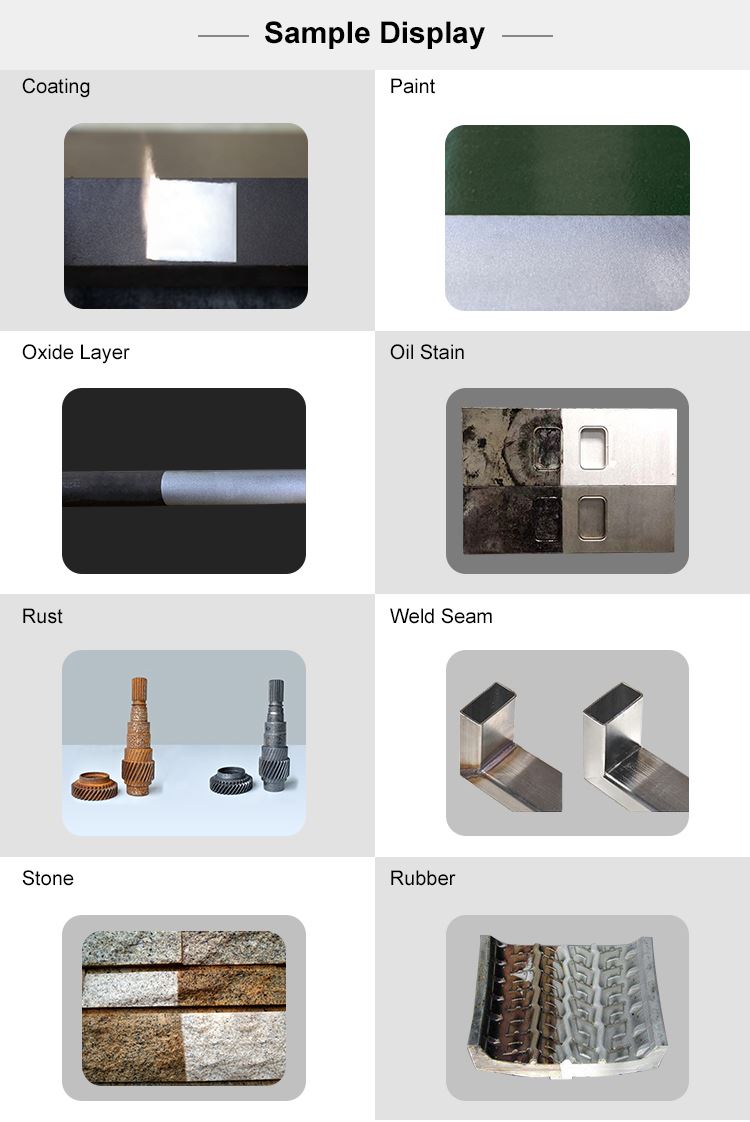

💍 Applications of the Benchtop Jewelry Laser Welding Machine

The Benchtop Jewelry Laser Welding Machine is a versatile tool, ideal for a wide range of jewelry repair and design applications. Whether you’re working with gold, silver, platinum, or titanium, this machine’s high precision and efficiency make it perfect for a variety of tasks. Below are some key applications that showcase the power and flexibility of this machine:

1. 🔧 Ring Resizing and Adjustment

The Benchtop Jewelry Laser Welding Machine makes ring resizing a breeze. Whether you’re adding or removing material, you can achieve seamless, strong welds without affecting the ring’s original structure. Perfect for adjusting rings to fit a variety of sizes or creating custom designs.

- Ideal for: Wedding rings, engagement rings, and other custom jewelry.

2. 💎 Prong Repair and Reinforcement

If a gemstone’s prong becomes loose or damaged, the Benchtop Jewelry Laser Welding Machine allows for precise prong repairs. With laser welding, you can strengthen or replace prongs without disturbing the gemstone or surrounding materials, ensuring that the precious stone stays securely in place.

- Ideal for: Setting or resetting gemstones like diamonds, sapphires, or emeralds.

3. 🔗 Chain Repair and Restoration

Broken chains can now be fixed quickly and efficiently with laser welding. The Benchtop Jewelry Laser Welding Machine offers the precision necessary to restore chains to their original form, eliminating the need for traditional soldering. This results in smoother joints with less heat distortion.

- Ideal for: Gold, silver, and delicate chain repairs.

4. 🔨 Porosity Filling and Casting Repairs

Over time, casting defects such as porosity can weaken jewelry. The Benchtop Jewelry Laser Welding Machine offers a quick, reliable solution by filling voids in the metal. This ensures the structural integrity of your jewelry while maintaining its aesthetic quality.

- Ideal for: Jewelry casting repairs and addressing manufacturing defects.

5. 🪄 Fine Detail Welding

For intricate, detailed jewelry pieces, the Benchtop Jewelry Laser Welding Machine provides superior precision for small, complex welds. Whether you’re creating fine designs or repairing delicate components, the focused laser ensures perfect results every time.

- Ideal for: Filigree, engraving, and detailed custom designs.

6. 🔧 Quick Fixes for Everyday Repairs

The Benchtop Jewelry Laser Welding Machine is perfect for jewelers who need to perform quick repairs without sacrificing quality. Whether it’s a broken clasp, loose setting, or minor crack, this machine allows you to repair jewelry efficiently, saving time and resources.

- Ideal for: Quick fixes for everyday jewelry maintenance.

7. 🏆 Custom Jewelry Creation

For jewelers looking to create custom pieces, this machine offers unmatched flexibility. From adding decorative elements to welding unique designs, the Benchtop Jewelry Laser Welding Machine is the perfect tool for bringing your creative vision to life.

- Ideal for: Jewelry designers and custom shops offering bespoke pieces.

💡 In Summary:

The Benchtop Jewelry Laser Welding Machine is a highly versatile tool that meets the needs of jewelers across various applications. From ring resizing and prong repairs to chain restoration and casting repairs, its precision and power make it an essential asset for both repair and custom jewelry creation. Whether you’re working on small-scale repairs or complex designs, this machine helps ensure your jewelry is crafted to perfection.

FAQ – Benchtop Jewelry Laser Welding Machine

1️⃣ What is a Benchtop Jewelry Laser Welding Machine?

A Benchtop Jewelry Laser Welding Machine is a compact, high-precision welding tool designed for delicate jewelry repairs and fabrication. It uses focused laser energy to weld metals together with extreme accuracy, making it ideal for working on small, intricate pieces such as rings, bracelets, and pendants.

2️⃣ How does a Benchtop Jewelry Laser Welding Machine work?

The machine directs a focused laser beam at the joint area of the metals to be welded. The intense heat from the laser melts the metal, allowing it to fuse together. The process is highly controlled, so you can make precise, strong welds without affecting the surrounding areas of the jewelry.

3️⃣ What materials can be welded with this machine?

Benchtop jewelry laser welders are typically used for welding precious metals like gold, silver, platinum, and their alloys. Some models can also handle base metals such as copper and stainless steel, although the settings may need to be adjusted accordingly.

4️⃣ What are the advantages of a Benchtop Jewelry Laser Welding Machine?

- Precision: The laser’s focused energy allows for precise welds, even on intricate jewelry designs.

- Minimal Heat Affected Zone (HAZ): The heat generated by the laser is concentrated only on the weld area, reducing the risk of damage to surrounding material.

- No Need for Filler Material: In many cases, the laser welding process doesn’t require filler material, which preserves the piece’s aesthetics.

- Clean, Smooth Welds: The welding process produces a clean and smooth finish, eliminating the need for additional finishing work.

- Compact Size: Benchtop models are smaller and more versatile, taking up less space than larger machines, making them ideal for smaller workshops or jewelry stores.

5️⃣ Is the Benchtop Jewelry Laser Welding Machine easy to operate?

Yes, most benchtop models are designed with user-friendliness in mind. They typically feature intuitive touchscreen controls, adjustable power settings, and fine-tuning options for different materials. While training may be required to get familiar with the machine, it is usually quick to learn for most users.

6️⃣ Can the machine be used for jewelry repair?

Absolutely. Benchtop jewelry laser welders are commonly used for repairing jewelry, such as resizing rings, reattaching stones, fixing clasps, and even restoring damaged pieces. Their precision allows for repairs without disrupting the overall design of the jewelry.

7️⃣ What safety measures should be followed when using the machine?

- Eye Protection: Always wear laser safety goggles to protect your eyes from the high-intensity light produced by the laser.

- Ventilation: Ensure proper ventilation in the workspace to eliminate any harmful fumes that may be produced during welding.

- Protective Gear: Wear appropriate gloves and clothing to prevent burns or injury from the laser or molten metal.

- Machine Safety Lock: Many machines have a safety lock feature that prevents accidental activation, enhancing overall safety.

8️⃣ How does the Benchtop Jewelry Laser Welding Machine compare to other types of welders?

Benchtop jewelry laser welders are smaller and more precise than larger industrial laser welders, making them ideal for delicate work on jewelry. They also provide more control over the heat output, which helps preserve the fine details of the jewelry. In comparison to traditional welding methods, the laser welding process is cleaner, faster, and more accurate, with minimal distortion of the material.

9️⃣ What is the price range of a Benchtop Jewelry Laser Welding Machine?

The price of a benchtop laser welding machine typically ranges from $3,000 to $15,000 USD, depending on the brand, features, and power capabilities. While the initial cost may seem high, the machine’s precision, speed, and ability to eliminate the need for additional labor or repairs make it a worthwhile investment in the long run.

🔟 How often should the Benchtop Jewelry Laser Welding Machine be maintained?

Regular maintenance is key to keeping the machine in optimal condition:

- Clean the laser lens and mirrors to ensure clear, effective welding.

- Check and maintain the cooling system to prevent overheating.

- Ensure the machine is properly calibrated for accurate welds.

- Regularly inspect the system for any signs of wear or damage, such as worn-out parts or faulty electrical components.

Jewelry Laser Welding Video

Request a Quote for a Jewelry Laser Welding Machine

SISMAR LASER has laser welding machine and other solutions for many industrial applications. Our solutions can serve as an upgrade to your existing laser welding system or an excellent choice for your first laser machine.

Request a quote for a high-quality jewelry laser welding machine that exceeds your expectations. You can also schedule a demo to see how jewelry laser welding machine works.

welcome to SISMAR laser. very glad to answer any questions about our fiber laser marking/cutting machines.