Author Archive for: linda

About linda

This author has yet to write their bio.Meanwhile lets just say that we are proud linda contributed a whooping 106 entries.

Entries by linda

3D laser marking machine

September 15, 2020 /0 Comments/in Blog /by linda14 Websites to find DXF/PLT files for laser engraving,marking cutting

July 28, 2020 /0 Comments/in Blog /by lindaHow to laser cleaning machine works?

July 2, 2020 /0 Comments/in Blog /by lindaSISMAR LASER Hand-Held/Portable Laser Cleaning Machine FAQ

July 1, 2020 /0 Comments/in Blog /by lindaHandheld Laser Cleaning Machine

June 30, 2020 /0 Comments/in Products /by linda

Portable/Handheld Laser Cleaning Machine

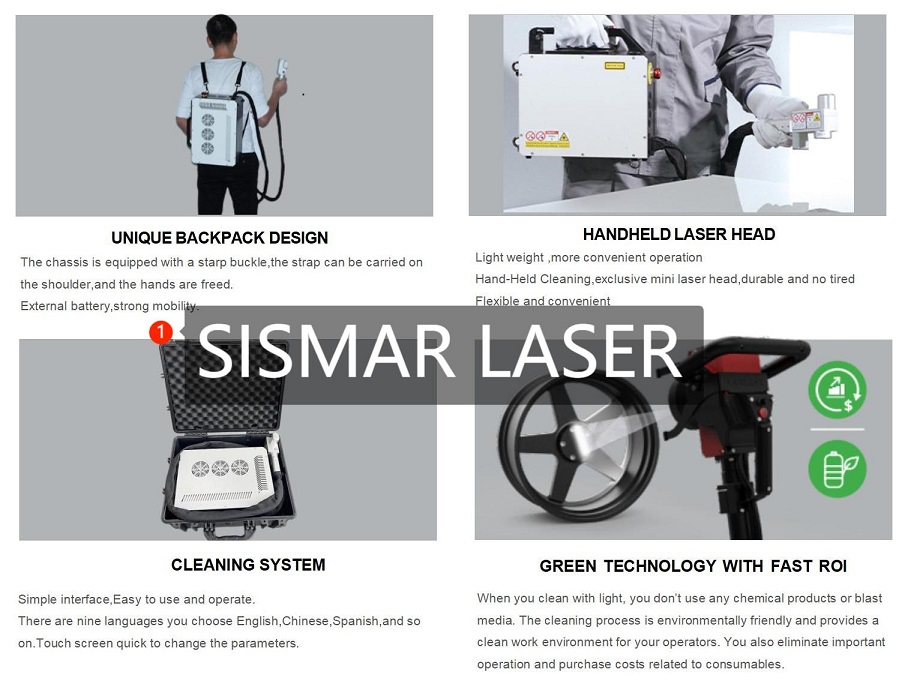

The Backpack handheld pulsed laser cleaning machine for rust paint oil removal portable laser cleaner,also called Laser Rust Removal System.

1. 50w 100W backpack handheld laser cleaning machine is a “Environmental friendly” cleaning machine. It does not need to use any chemicals and cleaning fluids. The cleaned waste is basically solid powder, small in size, easy to store, recyclable, and can easily solve chemical cleaning problems.

2. Its biggest advantage is that it is light and portable. Compared with large machines, it is more suitable for home use, does not take up space, and is easy to operate. Using laser technology to quickly peel off rust, oil, paint, and a wide range of applications.

The backpack laser cleaning machine is a pulsed Gaussian laser cleaning machine with the minimum power (50W/100W)

At the same time, it is equipped with the function of a backpack. If you go out for cleaning services, or take it out to meet customers, it is a very good economical pulsed laser cleaning machine.

The weight of the whole machine is not To 8 kg, anyone can learn and use it within 1 hour without any skills and professional skills.

Advantage of Handheld/Portable Laser Cleaning Machine

- It’s a non-contact, non-abrasive process. Home remedies are messy and unhealthy. Scrubbing off rusted surfaces exposes you to impurities which could lead to respiratory complications. Laser cleaning, on the other hand, relies on the laser beam to ablate the surface. There is no physical contact between you and the rust.

- No use of chemicals. Rust remover chemicals can get the job done, but the health implications on their use outweigh their benefit. Such chemicals are not only harsh and abrasive but also emit intense fumes. You will need to wear protective gear such as a respirator, goggles and rubber gloves before using them. However, laser cleaning does not rely on any chemical application. It is the better choice as it does not put your health at risk.

- No secondary waste is produced. Scrubbing off rust from surfaces only disintegrates the rusty particles from the substrate, leaving you with a toxic lump of rust dust at the end of the process. Electrolysis leaves the rust particles floating in the water, which you later have to dispose of. In comparison, laser cleaning is a cleaner process as the rust particles are either vaporized or turned into plasma, leaving no evidence of waste.

- High precision. The focused laser beams have an extremely precise focal edge, allowing you to ablate rust from tough spots that would otherwise be harder to clean with other apparatus. Such include the rust that develops around bolts and rails. Additionally, the high precision allows you to focus the laser beam repeatedly over a specific area to achieve the required depth and result.

- It’s effective on all surfaces. Unlike other rust removal procedures, laser cleaning works on all surfaces that are prone to rusting, including stones, concrete, iron, aluminum (bauxite) or copper.

- It does not degrade the substrate. Scrubbing rusted surfaces significantly degrades the substrate due to friction. Rust removing chemicals, on the other hand, are harsh and corrosive, causing wear and tear that could spoil delicate metals or even weaken their robustness. Laser cleaning in comparison ablates the surface while leaving the substrate untouched.

- It is a long-term solution. A laser cleaning machine will serve you longer than any scrubber or rust removing chemical will. The laser does not suffer any wear or tear, and thus can be used and reused over its lifetime.

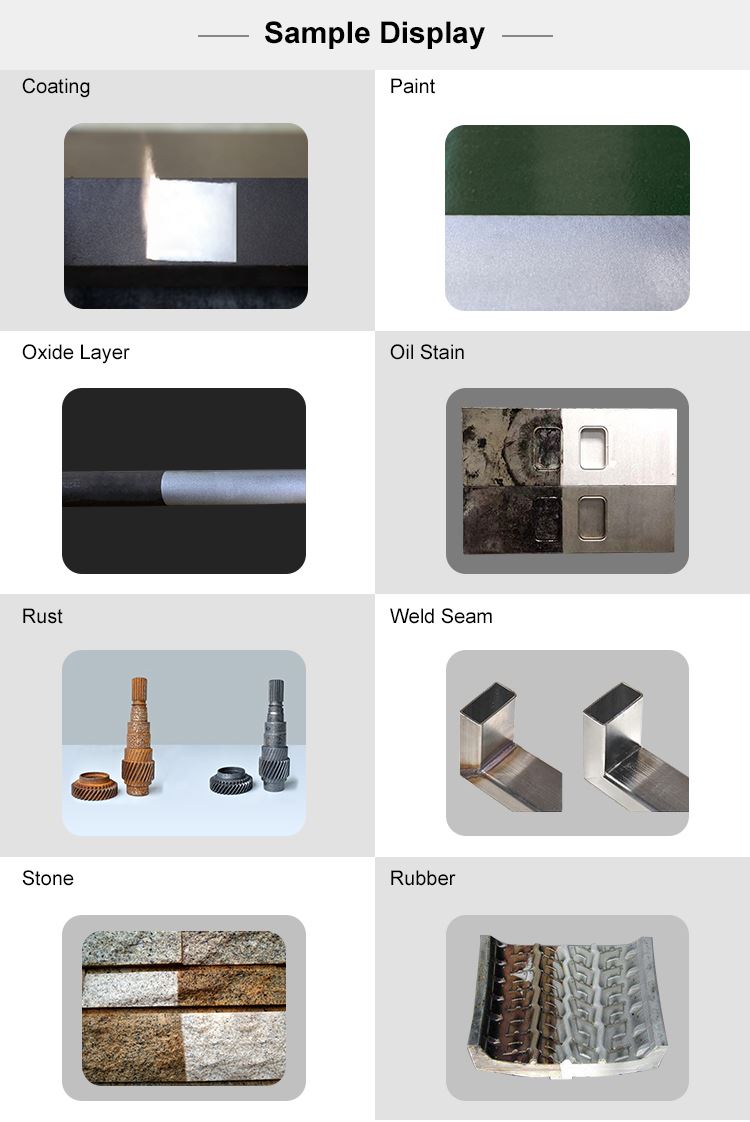

1.Metal surface rust,

2.Surface paint stripping treatment,

3.Surface oil, stains, dirt cleaning,

4.Surface coating, coating removal,

5.Welding surface / spray surface pretreatment,

6.Stone surface dust and attachments removed,

7.Rubber mold residue cleaning.

Videos of Backpack laser cleaning machine

CCD Visual Localization Laser Marking Machine

May 31, 2020 /0 Comments/in Products /by linda

Visual Localization Laser Marking Machine

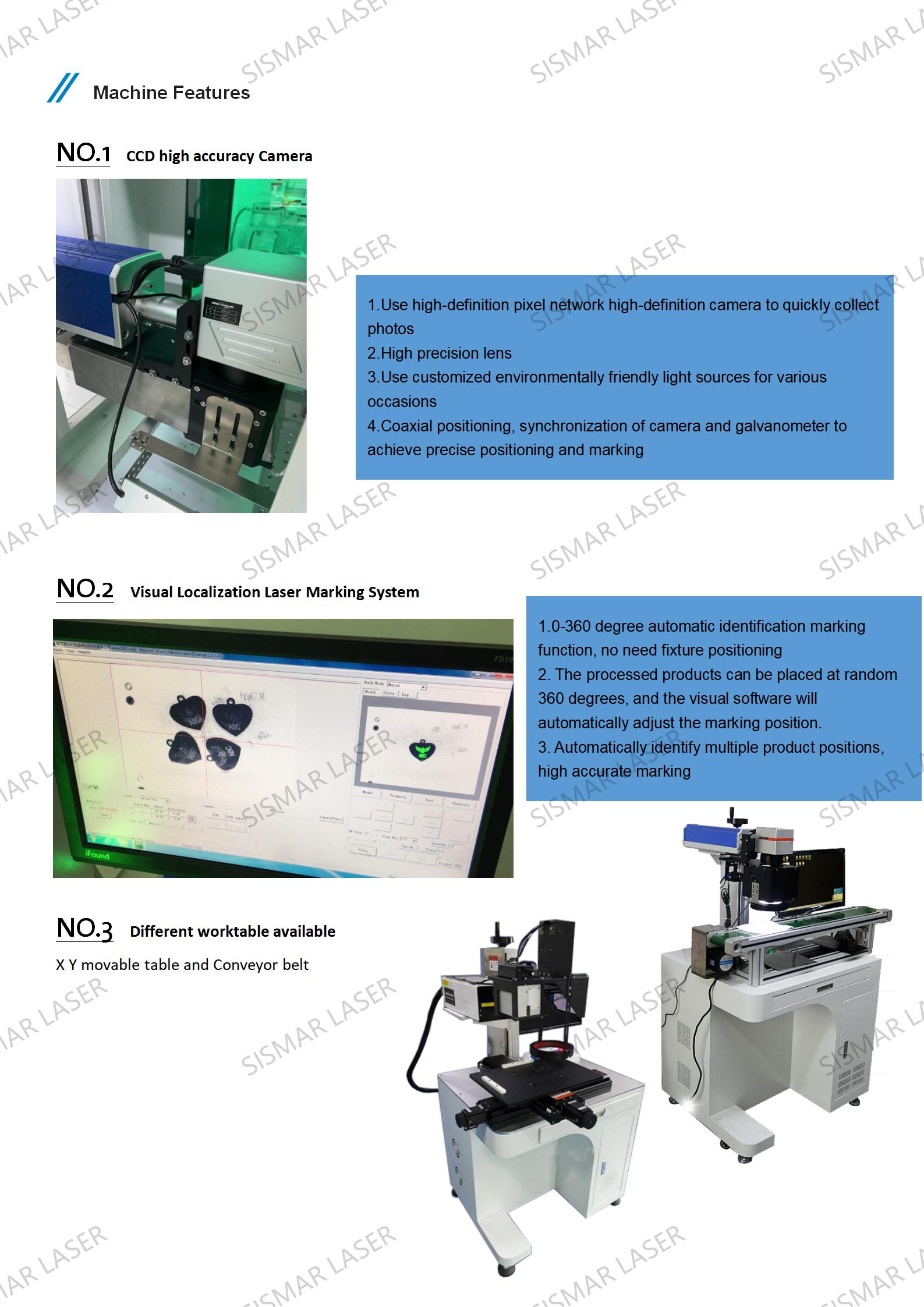

Visual Position Laser Marking machine also called CCD laser marking machine and CCD Visual Position Laser Marking Machine.

CCD laser marking machine is actionable to locate the printing position and angle of the targeted parts and achieve the precise marking without the position fixture, and the marking accuracy can be controlled among 0.01mm.

CCD laser marking machine is suitable the use of marking irregular, different and small sizes parts and parts that need lots of location fixtures at high costs.

CCD visual Position Laser Marking Machine Photo

During the marking process, the processed parts must be in a fixed position and must not be shaken during the process.

The processed patterns can be processed to the designated position of the product. These are our common knowledge of the processing technology of traditional laser marking machines.

In the process of product marking, traditional laser marking machines need to customize simple or complex jigs for positioning, and will encounter the following problems.

When the traditional laser marking machine needs to realize automatic production, it has high requirements on mechanical accuracy. Making a complex automation supporting line can only be applied to one or a few products. For new products, it is necessary to make new production lines, which is not only long-term but also very unfavorable to the cost management of the factory.

The core function of the CCD visual positioning laser marking machine is the CCD visual positioning function. This function can automatically identify product features for laser marking to achieve fast positioning, and even small objects can be marked with high precision, without the need to use fixtures, reducing With manual participation, work efficiency is improved.

CCD Visual Position Laser Marking Video

3D Fiber Laser Marking Machine

May 30, 2020 /0 Comments/in Products /by linda

3D Fiber laser Marking Machine

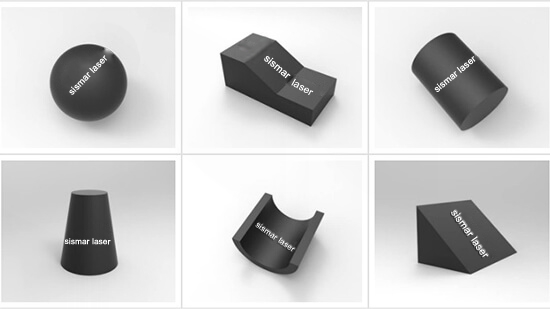

SISMAR LASER 3D Fiber Laser Marking System can laser mark and engrave over curved and irregular surfaces. This Laser Engraving and Marking machine incorporates an RAYCUS/JPT/IPG Fiber Laser. This is a low maintenance laser with a life expectancy of 50,000 to 100,000 hours of worry free operation.

SISMAR LASER fiber laser marking machine adopt imported core components, with high-speed, high precision 3D galvo, and with our 3D specified software and control system, it can engrave on any curved workpieces in a fine process, there is no off-focus problem. It can also adjust focus length any time for deep engraving, which makes process efficiency and marking quality much better than traditional 2D fiber laser marking machine. We make real 3D marking function come true, leading a new era of laser processing.

|

model |

SL-3D30W |

SL-3D50W |

SL-3D100W |

|

Output power |

30W |

50W |

100W |

|

Pulse power |

1MJ |

1MJ |

1MJ |

|

Repetitive Rate |

30K-200KHZ |

50K-200KHZ |

50K-200KHZ |

|

Wavelength |

1064nm |

||

|

Guide laser |

Red light/655nm wavelength/output1.0mw |

||

|

Marking range |

140mm*140mm |

||

|

Optional marking range |

70mm*70mm/100mm*100mm/170mm*170mm/200mm*200mm/300mm≤400mm |

||

|

Hight/Depth range |

±20mm |

||

|

Marking model |

XYZ axis dynamic focusing |

||

|

Min line width |

0.03mm |

||

|

Marking speed |

≤10000mm/s |

||

|

Operate system |

WIN7/WINXP |

||

|

Support font |

True type,AUTOCAD,Others |

||

|

1D barcode |

CODE39/CODE128/TIF/CODABAR/EAN/UPC |

||

|

2D barcode |

QR/PDF417/DATA Matrix(ECC220) |

||

|

Support format |

PLT/DXF/DWG/SVG/STL/BMP/JPG/PNG/TIF |

||

|

Working environment |

Temperature:10℃-35℃ Humidity 5%/75% |

||

|

Power consumption |

Single phase 110v/220v optional/50-60HZ |

||

|

Cooling way |

Air cooling |

||

Differences between 2D and 3D laser marking machine

1). 3D means Dynamic focusing, compare with ordinary 2D laser machine, 3D laser marking machine adopts different galvo head. Ordinary 2D scanning head only have two mirrors, but 3D scanning head have three mirrors. The third mirrors can move forward and backward. This is the key technology of 3D laser marking machine.

2). 3D laser marking machine outstanding functions are deep engraving, relief engraving and curve metal marking.

3). When 2D laser need to mark curve surface, it should be added one rotary fixture. However,3D laser marking machine can mark curve metal directly. Higher speed and higher precision. Mostly, easy to operation.

4). 3D laser marking machine is coming with 3D galvanometer head and 3D software. Other parts almost the same as 2D laser marking machine.

SISMAR LASER 3D fiber laser marking machine allows you to be able to do relief engraving,so you can get phenomenal amount of textures and detail by importing an STL file,the process that we use is very similar to 3d printing,and it’s really unlimted on how deep you can go with 3D laser machine.

It is able to mark on a complex curve,so you’re able to mark on a sweat surface,on a sphere or even a 45-degree angle,no longer do you have to be on 2d plane you’ve got full freedom on marking on any complex shape that you would like.

CCD Camera Laser Marking Machine With Visual Localization system

April 22, 2020 /0 Comments/in Blog /by lindaCan you clearly identify the ” laser ID card “of the surgical mask?

April 18, 2020 /0 Comments/in Blog /by lindaCONTACT US

Add: Kaituo Road, High-tech Zone, Jinan City, Shandong Province

Tel: +86-531-88804407

Fax: +86-531-88804407

Email: sales@sismarlaser.com

LATEST PRODUCTS

- Comparision of Laser glass drilling machine Green Laser VS M8 fiber laserApril 28, 2024 - 3:25 am

- Comparison of three processes for glass cutting/drilling MachineApril 28, 2024 - 3:10 am

- 3D Subsurface Laser Engraving Machine For Crystal & GlassApril 9, 2024 - 7:09 am

- Why Glass Sandlasting with fiber laser marking machine?March 29, 2024 - 1:26 am

- The difference between single mode and multi-mode in laser cleaning machineJanuary 23, 2024 - 7:17 am